What is the cold chain?

INTARCON2022-06-03T09:56:20+02:00The cold chain is of vital importance nowadays. If you look at your daily consumption of food products, you will see that most of them are perishable (meat, fish, fruit, vegetables, etc.), making it essential for their safety to be guaranteed, thus preventing any potential health problems.

What is the cold chain?

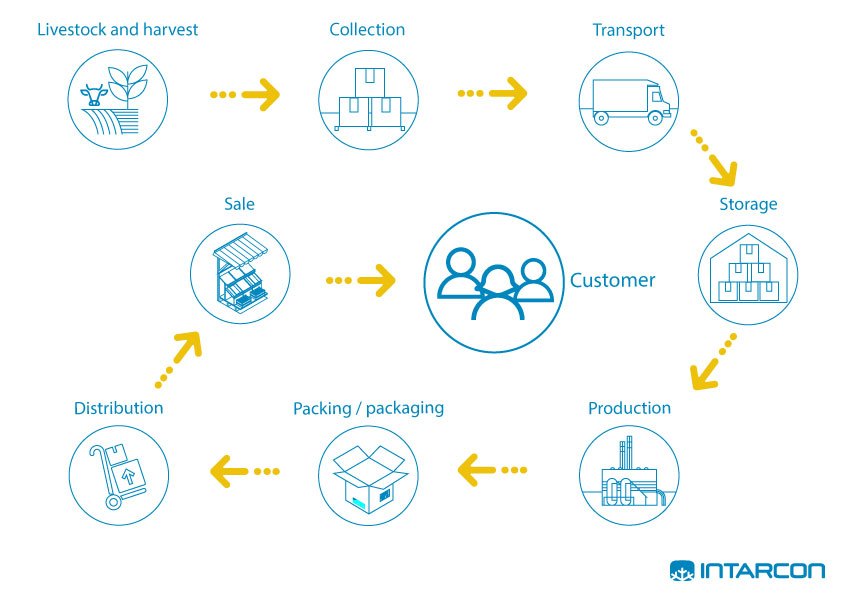

We know that it is essential to maintain and/or control the preservation and refrigeration temperature of food products within reasonable limits to guarantee the safety of food products. According to the cold chain concept, this safety will be fully guaranteed only if that temperature control is maintained during each and every phase of the food product, from the collection of raw materials to consumption of the food product by the end consumer.

Why is it important?

The cold chain of a food product is considered to have been respected when it has been subjected to constant temperature control throughout the process that occurs from production of the food product until its consumption. It must also be ensured that the temperature is kept within a set range (preventing significant fluctuations), which is specific to each type of food product.

We refer to this process as a “chain”, as it actually consists of several interrelated processes: collection of raw materials, transport of raw materials, storage, processing, packing and packaging, storage, distribution, storage at the point of sale, transport to the point of consumption and storage at the point of consumption.

The cold chain must be respected for all raw materials and food products whose stability at ambient temperature could be affected. As such, in addition to maintaining stability, we also extend the useful life, ensuring that nutritional and organoleptic properties are maintained, as well as the safety of the product for human consumption.

What happens if the cold chain is broken?

When you defrost a frozen food product (temperature > -18°C), even partially for a short time (a few minutes), microbial activity will resume to a lesser or greater extent. If you reduce the temperature again and refreeze it, this activity will stop, but there will be a greater number of micro-organisms than before and the food product will have some degree of deterioration that will be more or less noticeable. Breaking the cold chain has the following consequences:

- Risk of poisoning

- Reduced preservation time

- Loss of quality: appearance of bacteria, nutritional loss, bad smells, etc.

This is why it is very important to keep refrigerators at a suitable temperature that is as constant as possible. It should be noted at this point that any food product that has been defrosted must not be refrozen, unless it has been processed and cooked at temperatures above 70°C.

How can you tell if the cold chain has been broken?

Knowing whether the cold chain of a food product has been broken or not can be complicated for the end consumer, as there are no signs that indicate this. In the case of frozen products, there are some clues that the product has not been kept at the right temperature at some point.

- Frost formation: when you increase the temperature of a frozen product, it releases part of its content as water into its immediate environment. By refreezing it, this water will turn into frost, either on the food product itself or inside the packaging. It may even compress the food product, forming blocks.

- Condition of the packaging: in the case of products packaged in cardboard boxes, if you find a package that is too soft, that should raise suspicion.

- Defrost time: If the defrost time is very short, it may indicate that the food product was not stored at the right temperature (< -18°C).

How is it maintained and guaranteed?

To maintain and guarantee the cold chain, it is necessary to:

- Hermetically package the food products

- Store food products in specific cold rooms

- Keep food products at a temperature < -18°C in all processes

- Use specialised transport

- Measure and control the temperature throughout the chain

- We also recommend that the refrigeration installation has a monitoring and control system, such as Kiconex. Ideally, the system will feature a predictive maintenance function that can act on the refrigeration system. As such, it will be able to detect the deterioration or breakage of a device before it occurs. All of this means that food safety is practically 100% guaranteed