Water cooling in food and post-harvest processes

INTARCON2024-12-11T13:33:08+01:00By water cooling we mean the use of refrigerated mains water to counteract rising temperatures in food processes. This allows the control of fermentation, the proliferation of micro-organisms and the guarantee of food safety in the production of products (bakery, meat preparations, etc.).

Post-harvest treatments are also applied in order to obtain a food product with the best organoleptic qualities. Techniques such as hydrocooling help to maintain these qualities during storage and transport. This technique stands out for its capacity to slow down the ripening of the fruit by pre-cooling it quickly and efficiently by cooling it with water. In addition to reducing the thermal load in the chambers, this also helps to reduce one of the great problems of post-harvest: discards.

Water cooling in food processes.

In addition to water cooling for ice production, tap water cooling is applied in order to control temperatures during the production process. This allows to control the growth of micro-organisms, or to perform a thermal shock by mixing it with chilled water, highlighting the following stages of food processes:

- Dilution of concentrates in the production of drinks (juices and soft drinks) and the production of sauces and dressings.

- Mixing of dry ingredients, and temperature control in baking, for fermentation control.

- Mixing of dry ingredients with water to maintain proper temperature and adjust consistency in the production of ice cream, sorbets and bakery products.

- Preparation of pharmaceuticals.

- Cooling of perishable products such as soups and broths.

- In the sausage industry to avoid temperature increase during the mixing process of ingredients.

- Seafood processing for cooling, thawing, cooking or holding.

In addition to temperature control, water quality control must also be carried out. There are parameters that must be controlled by sensory analysis (such as odour, taste, colour and turbidity) and other physicochemical parameters (such as pH, conductivity, ammonium, bacteria, free residual chlorine and some metals).

In these systems, the use of removable food-grade plate heat exchangers stands out, which, thanks to their design, facilitate cleaning and thus the efficiency of energy transfer and water quality.

The importance of water pre-cooling in post-harvest.

Temperature is the most relevant factor affecting the deterioration of harvested fresh produce, directly affecting its respiration rate and the release of ethylene that promotes its ripening. Temperature lowering is one of the most efficient post-harvest techniques to maintain the quality of fruit and vegetables and extend their marketing period. This technique is based on the need to reduce the temperature quickly to the minimum safe value. In addition, water pre-cooling reduces the thermal load in cold storage and transport systems.

Water pre-cooling is a service increasingly demanded by the most demanding consumers. This technique makes it easier to obtain a product of the highest quality by making it possible to harvest at the optimum point of harvesting, and to increase the shelf life of fresh produce.

This reduces moisture loss, allows for higher sugar content, greater firmness and texture and limits the increase in fibre content.

The use of other harvesting techniques, such as harvesting at the ripe green stage, results in fruit without the organoleptic characteristics that are currently in demand by consumers. Another aspect to highlight is the commercial opportunity for crops of early varieties that are harvested in summer or early autumn, by allowing the reduction of high environmental temperatures and the heat coming from the field.

Pre-cooling techniques.

Pre-cooling techniques for rapid removal of heat from the field include:

- By air, it consists of the forced passage of air through the product at a speed of between 1 and 5 m/s, which increases the heat transfer process, highlighting the use of cooling tunnels.

- By water (or hydrocooling), consists of spraying or immersing products in cold water, removing heat from the product and reducing its temperature. This technique stands out for its efficiency and rapid cooling, thanks to the increase in the heat transfer coefficient with the surface of the product. There are two types, by showering or immersion of the product.

- With ice, it consists of the direct application of ice in the product container.

- Vacuum cooling consists of cooling by evaporation of moisture from inside the product under vacuum or low pressure conditions.

- In a chamber, the heat is removed slowly, requiring chambers with a higher installed power and a high air circulation capacity. Normally with a reduced height and lower load.

Water pre-cooling by hydrocooling.

Hydrocooling consists of the application of cold water in the temperature range of 1 to 5 ºC, in order to carry out a rapid cooling of the product thanks to the high thermal exchange capacity of the water. This system reduces the typical dehydration generated by air cooling in the refrigeration chambers, and allows obtaining a product of greater firmness and texture, reducing the losses during post-harvest.

The hydrocooling technique can be applied by different equipment designs and application methods such as: cold shower, water basin, immersion, drencher, washing machine, etc.

At the moment, it is being implemented in:

- Fruits (peaches, cherries, pears, nectarines, etc.).

- Vegetables (potatoes, beetroot, carrots, peppers, etc.).

- Other fruits (e.g. strawberries, red berries, blueberries) because of their easy application.

- Fish.

- Meat.

- Ready meals and sauces.

Beneficios del hidrocooling

The high heat transfer capacity of the water increases the energy efficiency of the system to lower the high reception temperatures of the fruit coming from the field (from 30 to 2 ºC) in order to reduce fruit respiration and increase storage time without deterioration. This allows harvesting at its optimum point, obtaining the best organoleptic properties. The time the product needs to cool is related to the size, the skin and the flow rate of the cooled water. The benefits of hydrocooling include:

- Scalable, modular and mobile system at the harvest.

- Increased energy efficiency in product cooling.

- Reduction of product cooling time.

- Reducing the sizing of equipment for cold room refrigeration and electricity consumption.

- Maintenance of fruit integrity (texture, colour, etc.) and less weight loss.

- Reduction and delay of the onset of cold damage.

- Delaying the appearance of browning inside the product.

- Increased product shelf life.

- Disinfection and preservation products can be applied.

- Cooling of a large quantity of product in the same day, as in-line cooling is possible.

Other benefits

Its application, in addition to the benefits obtained thanks to the rapid pre-cooling and reduction of product respiration, enables cleaning and disinfection after arrival from the field, allowing the elimination of phytosanitary products, pest control and pathogenic microorganisms such as insects, bacteria or fungi (Penicillium sp., Botrytis sp., Rhyzopus sp., Alternaria sp., Monilina sp., etc.), soluble solids in suspension and larger solids (dust, branches, leaves, etc.) that would negatively affect its sale and consumption, thus providing food safety to the product. This is why they require a water treatment system, by means of chemical disinfectants applied to refrigerated water such as sodium hypochlorite or ozone, or other non-chemical systems for pathogen control (such as UV-C light, ultrasound, etc.) and suspension of soluble solids (such as mechanical filtration).

Types of hydrocooling

There are two main types of hydrocooling:

- Static hydrocooling consists of the adaptation of a cabin with showers or a cold water tank where the product is introduced discontinuously by means of machinery external to the system, such as forklifts.

- Dinamic hydrocooling, the product is moved continuously within the system itself in hydrocooling tunnels by means of conveyor rollers or other mobile systems.

| Static | Dynamic |

| Productions up to 2,500 kg/h | All types of productions |

| Lower initial investment cost | Lower labour costs |

| Requires less equipment power | Better adaptability to food safety principles |

| Monitoring of the time spent inside the equipment | Adjusting the travel speed and length of the equipment |

INTARCON Solutions

INTARCON, thanks to its experience in the refrigeration sector, proposes different solutions for temperature control:

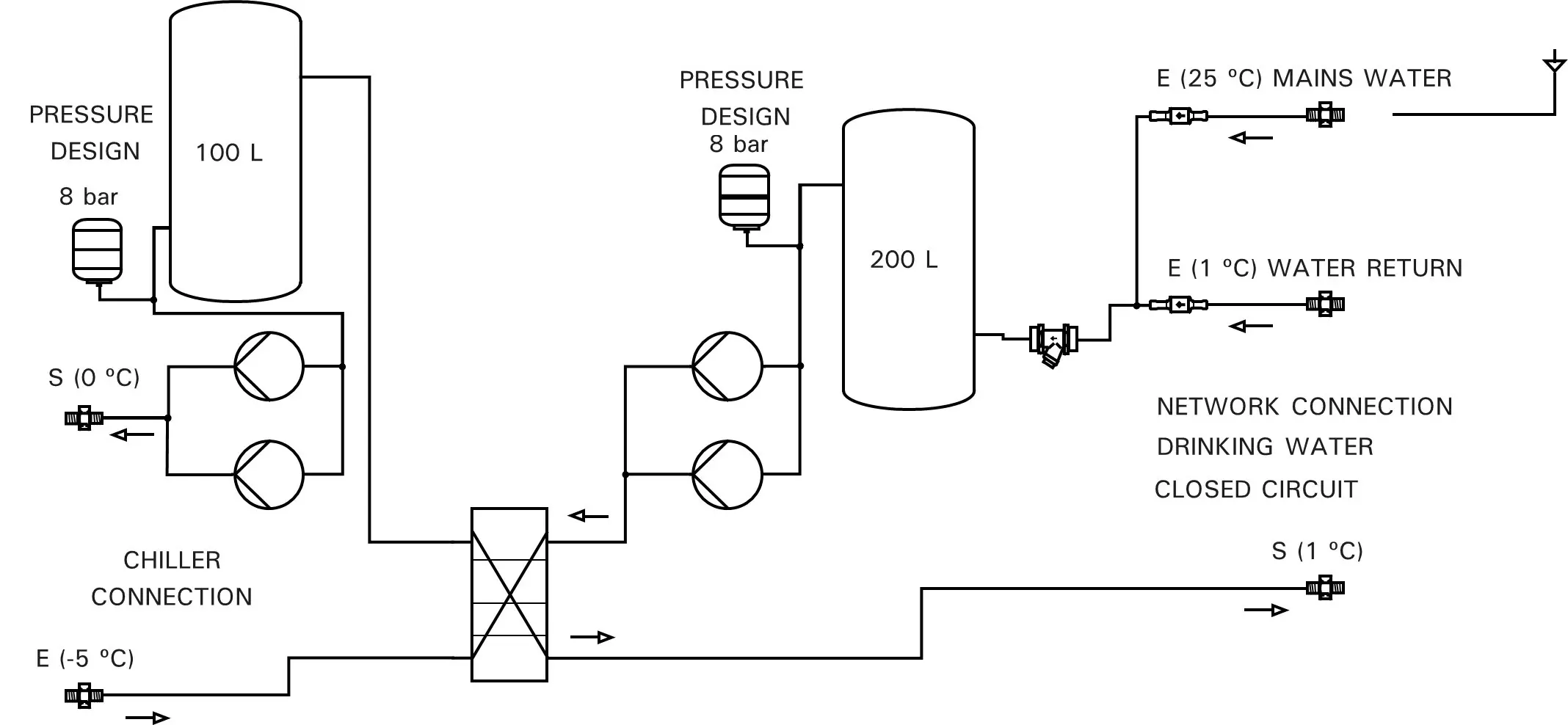

- Hydraulic units for cooling mains drinking water in a closed circuit, with a continuous recirculation system to reduce total water consumption and guarantee a constant temperature supply between +15 and +1 °C.

A schematic diagram of the principle of mains water cooling is shown below.

- Liquid chiller, notable for their reduced refrigerant charge and safety in the event of possible leaks in the refrigerant circuit. It stands out for its easy adaptation to a multi-service system by means of variations in the flow rate of the heat transfer fluid and independent cooling circuits.

Conclusions

The application of chilled water excels in its ability to control process temperatures quickly and efficiently, whether it be:

- In the lowering of product temperatures during pre-cooling in order to reduce discarding during storage and transport.

- In the control of the temperature throughout the production process by means of chilled water of a specific product that requires it, in order to obtain a product with the best qualities.