Strategies to reduce energy costs in refrigeration systems

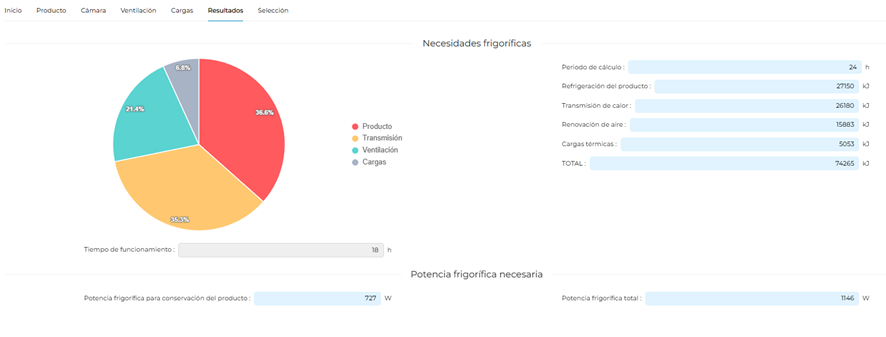

INTARCON2025-03-13T14:28:33+01:00Did you know that the thermal demand of a cold store or cold room depends on the following factors?

Key factors:

- Thermal loads due to heat transfer and ventilation: these depend directly on the outside temperature, the quality of the enclosure and the use.

- Product and internal loads: vary according to the use profile of the cold store and type of product.

The following is a strategy for reducing refrigeration costs:

On hotter days, the power requirement increases due to higher heat losses.

For installations with secondary fluids, CO₂ or ammonia in direct expansion, the power of the evaporators or evaporators will depend on the thermal jump. Raising the fluid temperature requires more time to deliver the same energy.

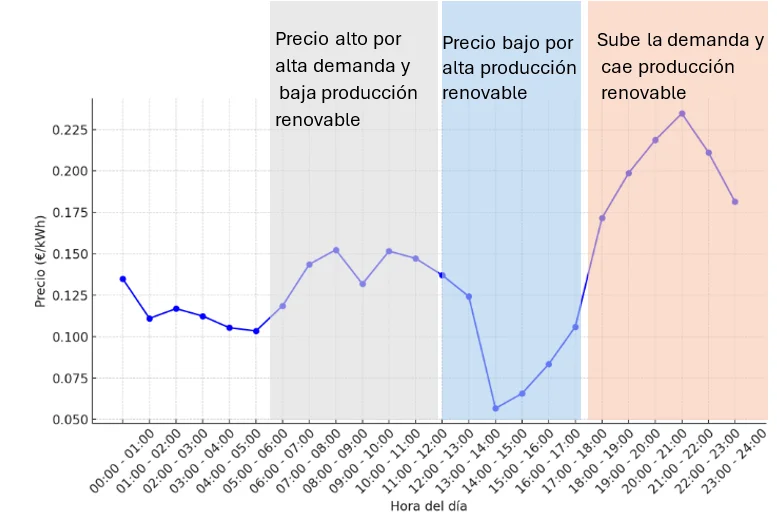

Summer price trend: an operational opportunity

On summer days, the price of electricity is usually lower in the middle hours of the day, thanks to the renewable mix. This opens up a great opportunity for the refrigeration industries. Why? Because the hottest hours of the day coincide with lower energy costs, creating significant savings potential

This price trend in the market is very interesting, especially if we are able to take advantage of the operational opportunities that refrigeration equipment allows us.

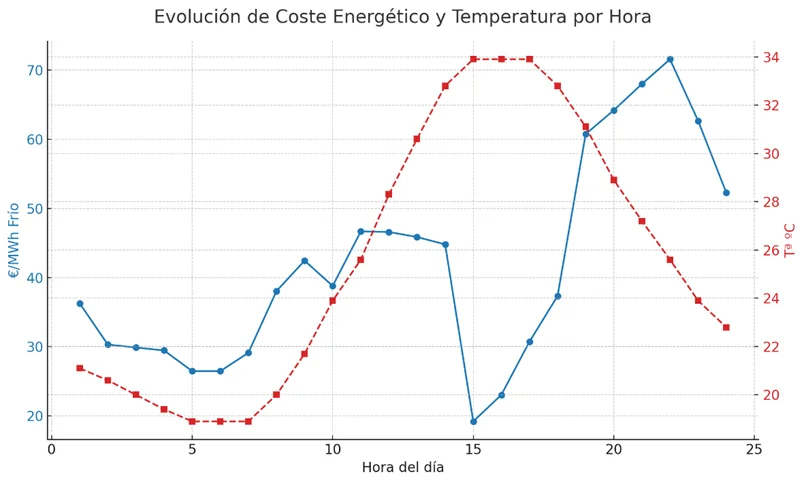

Practical example: Let’s analyse the energy cost per MWh refrigeration, hour by hour, during a summer day in Madrid. We consider:

- The COP of the compressors according to the outside temperature.

- The energy cost of the hourly market.

Results: The central hours of the day, with the highest thermal load, have the lowest energy cost.

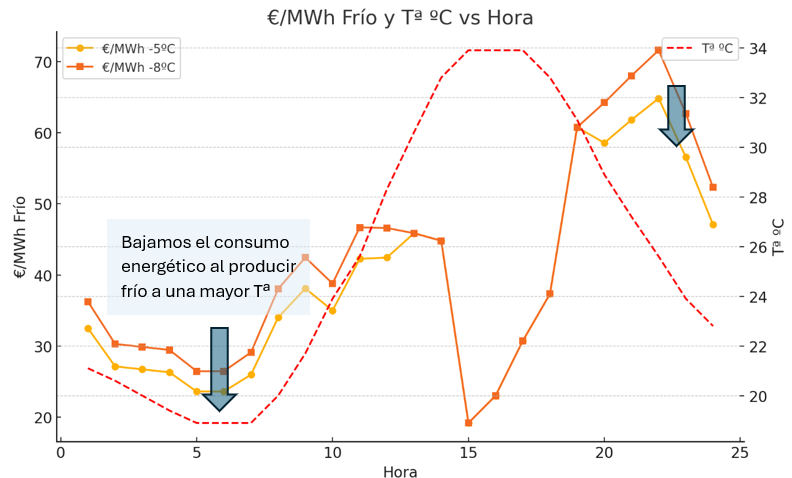

If we go further, this allows us to implement strategies such as changing the set point (glycol delivery or evaporation temperature) depending on the outside temperature. Thus, operating costs go down, since during hours with moderate temperatures, the evaporators or aeros are able to give the required power (which is lower) with less thermal jump.

This strategy leads to economic savings of between 6 and 8%, depending on how the external temperature and the price curve varies. Other strategies that can be interesting and make a lot of sense to implement:

- In case of having low temperature chambers, the thermal inertia of the chambers can be used to lower consumption in high cost hours and shift them.

- Depending on the defrosting method, it is interesting to analyze in which hours to focus it. For example, if we have electric defrosting, clearly we must force them in the central hour of the day to clean the ice in evaporators and cool again before the energy price rises again.

- If we have photovoltaic production, or other consumption in the installation, analyze the overall strategy that will improve the energy cost of the whole.

Intelligent control: the future of cooling

Increasingly, the control strategy will have more weight in operating costs. When investing in equipment, make sure that it allows you to implement optimization strategies in the future. Otherwise, you run the risk of acquiring equipment without the level of control needed to maximize efficiency.

- Conclusion: These simulations not only help to reduce costs, but also to choose the most appropriate energy tariff for each case.

Prepared by: Manuel García Jímenez