Refrigeration in olive oil production

The low harvest expectations for the next season, and the trend towards an early harvest to obtain oil, increases the interest in new harvesting, conservation and extraction techniques for the production of a higher quality oil. This situation means that refrigeration in oil production plays a fundamental role in obtaining a higher quality product.

History

The greatest degree of olive deterioration occurs between harvesting and processing.

Traditional harvesting techniques allowed for a staggered arrival of the fruit at the mill, with no waiting time for processing. The technique of “shaking” and dragging of nets results in the breaking and bruising of the fruit, being the initial sources for the propagation of rot during storage.

At present, the milling industry cannot process all the product immediately, piling the fruit in piles called “trojes” or in hoppers. This results in a caking that causes the physical destruction of the olives in the lower zone, releasing organic material that constitutes an excellent breeding ground for the proliferation of micro-organisms. In addition, the respiration of the fruit causes an increase in temperature, accelerating the whole degradation process, so it is not surprising that the oil obtained from these fruits is not suitable for consumption without prior refining. As highlighted by the University of Seville (CSIC) where: “Nearly 80% of the oils produced in the Mediterranean region have defective characteristics that make them unsuitable for consumption in the form in which they are obtained, if they are not previously subjected to the refining process” (Khaled Yousfi, 2008).

In order to obtain a high quality oil, the ideal method will be the one that preserves the integrity of the fruit to the greatest extent. This is why refrigeration in oil production can play an important role in obtaining a quality product.

Actuality

The characteristics defining the quality of the oil extracted (acidity, peroxide value, absorbance or sensory analysis) depend more on the quality of the olive than on its degree of ripeness.

As a result of climatic changes, the phenology of the olive tree is changing, bringing forward the optimum harvesting point. Furthermore, super-intensive farming with early varieties such as Arbequina and the growing interest in the “gourmet” market require early harvests to obtain the “green” or premium oil so highly endorsed by international competitions, this “green” name having more to do with its fruitiness and more intense and aromatic flavour than with the presence of chlorophylls that give it its colour.

All this is linked to the high temperatures that may occur at the beginning of the harvesting season of these varieties, daytime temperatures above 30 ºC. These are increased during transport because the fruit is breathing and giving off heat. In addition, caking leads to hypoxic conditions (absence of oxygen) which induce anaerobic respiration, causing undesired fermentations that develop oxidised compounds, giving the extracted oil detectable sensory defects and which may react with free fatty acids, leading to high levels of alkyl esters.

Furthermore, the increase in technology through the use of shakers, umbrellas or harvesters, and the current extension dedicated to its cultivation has increased the amount of fruit to be processed. Harvest peaks lead to the need for storage upon receipt, and thus to a higher probability of fruit degradation.

Problematic

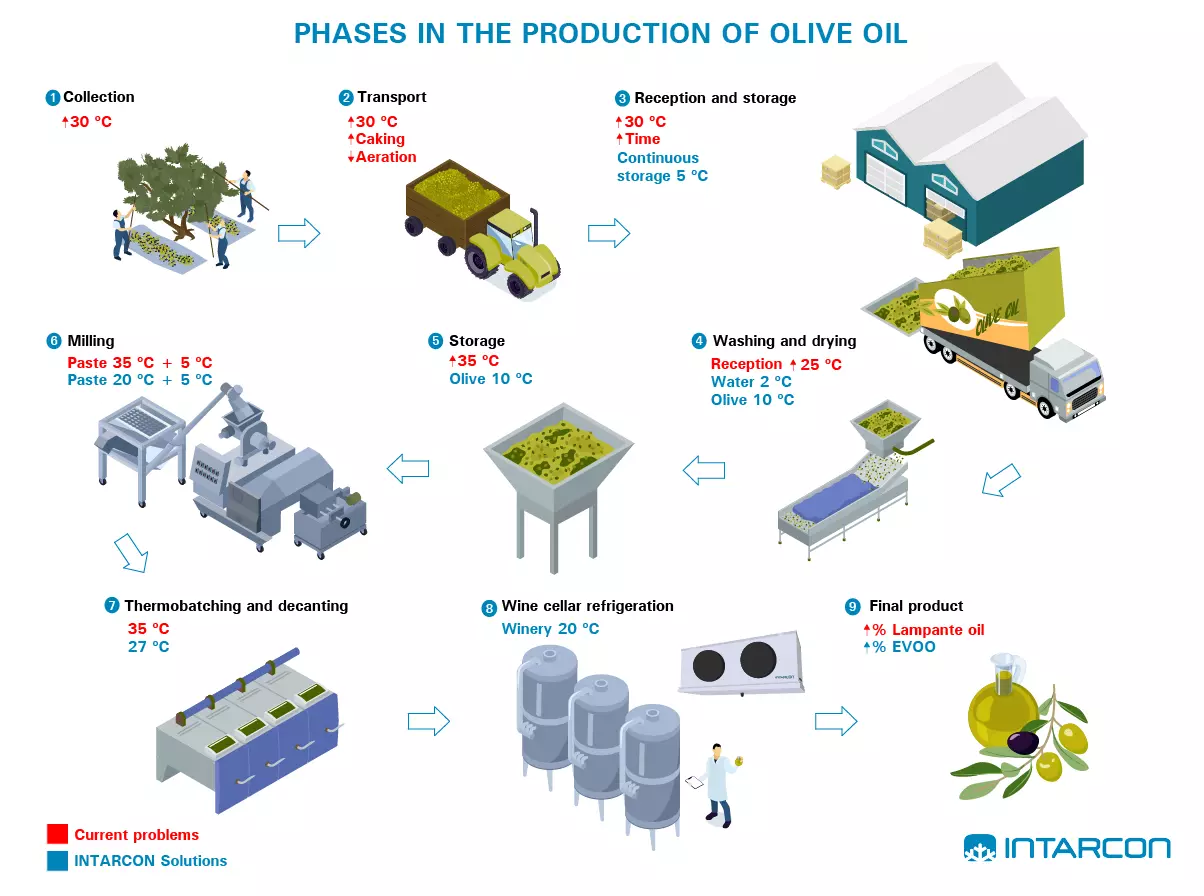

INTARCON’s collaboration with the different olive mills and farmers has made it possible to detect customers’ problems throughout the olive oil production phases:

- Harvesting, by shaking or shakers (with bales or inverted umbrellas) compared to the use of harvesters, with a considerable difference in the integrity of the fruit.

- Storage and transport, in large containers, suffering caking, hypoxia and increase of the temperature of the fruit, giving rise to deterioration reactions and loss of quality.

- Washing, of olives from the ground resulting in clouding of the wash water, with less clouding detected when using umbrella or harvester harvesting techniques.

- Milling, where the temperature is increased by 5 ºC due to the effect of friction, being a critical point in the chain due to the loss of volatile components linked to high temperatures.

- Thermo-beating, detecting high paste temperatures, defining the optimum temperature range for beating between 25 ºC and 29 ºC for optimum oil separation.

- Final product, large proportion of oil with refining requirements for consumption by extraction at high temperatures.

Refrigeration solutions in olive oil production

From Intarcon, thanks to the accumulated experience, together with the collaboration with the different oil mills in the area, and research and experimental cases by the scientific community. The need has been detected to control the temperatures to which the product to be processed is exposed, requiring refrigeration in the production of oil, to control the high temperatures, in order to slow down the conditions that degrade the product, allowing a higher quality product to be obtained.

Given that the fruit is of the non-climacteric type, refrigeration in oil production causes a delay in ripening, but not its complete interruption. According to the conclusions of the CSIC, “Under these conditions, the fruit dries out, inhibiting the enzymatic activities and thus reducing the intensity of bitterness, while the oil contained in the fruit remains unaltered, protected by the cell structure itself.” (Khaled Yousfi, 2008).

Intarcon therefore proposes different points of action for temperature control, as shown in the illustration and discussed below:

Phases and applications of refrigeration in olive oil production

Refrigerated storage

The respiration of the fruit and the accompanying heat production induces a self-induced accelerated process of the internal atmosphere of the container. This causes an increase in its temperature and, consequently, a severe deterioration process. According to studies carried out by the Department of Agricultural Chemistry of the University of Seville, “The efficacy of applying pre-cooling to olives, which were then stored at 5°C in 400 kg containers, has been demonstrated” (Eddy C. Plasquy, 2022).

And analyses carried out by the Instituto de la Grasa (CSIC) of the University of Seville, where “The quality of virgin oils obtained from olives stored at 5 ºC remained within the extra category for 18 days in all the parameters analysed, including acidity values” (M. Canet and J.M. García, 1999). They conclude that refrigerated storage counteracts fruit respiration, resulting in a delay in ripening during storage, as well as a delay in weight loss, changes in skin colour and softening of the stored fruit.

Washing and drying

Washing with cold water and drying with refrigerated air, being a very efficient method due to its high heat exchange capacity. Finally, allowing the removal of excess heat from the field quickly, and respiration during transport and storage.

Molturado

Water cooling of models with cooling systems included in their design.

Refrigeration of pasta

Temperature control at the outlet of the grinder by using double tube heat exchangers.

Thermo-whipping

Temperature control of the pulp during churning to allow extraction of the highest quality, with optimum temperatures between 25 and 29 ºC.

Final product

The use of cooling techniques that compensate for the respiration of the fruit results in a higher quality product without the need for refinement.

INTARCON Solutions

The permanent contact and collaboration with the oil mills has allowed Intarcon to propose solutions that adapt to the requirements and capacities of the customers.

Research in this area highlights the need for temperature control in the earliest stages of the process. In order to avoid the degradation of the fruit and volatilisation of volatile compounds, in order to obtain an extra category product.

INTARCON chiller plants

- Chiller plants for the application of a water loop serving:

- Cooling of the water basin in the washing stage.

- Aeration and conservation by means of air coolers condensing on the water loop.

- Adaptation to milling machine cooling systems.

- Refrigeration of the paste as it leaves the milling machine.

- Temperature control of the thermo-blender.

For this purpose, Intarcon presents the Full-Inverter chiller plants, which are characterised by their ability to modulate the cooling capacity. These units provide precise control over the glycol supply temperature in the face of a variable refrigeration demand. Thanks to the speed variation of the compressors, thus avoiding start/stops, with significant energy savings. In addition to using environmentally beneficial natural refrigerants and low charge as they are indirect systems, thus saving on maintenance costs.

Optional heat recovery

Solution to control the temperature at the inlet and during the beating process, for optimum oil extraction during the different harvesting periods. In addition to high temperature support, thanks to free heat recovery, for the extraction of the maximum volume of lower quality oil.

Conclusions

We have observed how the price of olive oil has increased considerably in recent years, highlighting the economic benefit of refrigerated storage. In order to avoid oxidation and loss of quality and, consequently, the loss of its market value over time, allowing the investment to be amortised in a shorter period of time.

We understand that refrigeration implies a cultural and dynamic change in the production of oil, although it entails an unavoidable investment, it is necessary. If quality is to be improved, this implementation can make these oils competitive with seed oils in the maximum development of their quality.

It is not necessary that all the production is destined to a top category oil, but by producing a part of it as the “Premium” range, it allows the creation of a brand which in turn serves as an umbrella for the rest of the oil.

Bibliography

- Development of post-harvest olive treatments to regulate the bitterness of virgin olive oil. Khaled Yousfi. Doctoral thesis. University of Seville (CSIC), 2008.

- Optimisation of harvesting and management of the temperature of the harvested olives. Guidelines for the production of high quality oils by small producers. Eddy Charles Albert Plasquy. Doctoral thesis. Department of Crystallography, Mineralogy and Agricultural Chemistry. University of Seville. 2022.

- Impact of the cold storage of mill olives on the virgin olive oil production process. Miguel Canet and José M. García. Cooperativa comarcal, Valencia. Instituto de la Grasa (CSIC), Seville. 1999.