Refrigeration in cheese dryers

INTARCON2024-03-14T08:42:44+01:00The cheese-making process begins with the production of milk, which must be of high quality, depending on animal health, hygiene and feeding. Once the milk is obtained, it must be kept at a low temperature and protected from sunlight and ultraviolet radiation in the cheese dryers to prevent bacterial growth.

To produce cheese, several kilograms of milk are needed, depending on the type of cheese desired. At the cheese factory, the milk is then tested for quality and cooled before being stored in tanks for processing. Before the manufacturing process begins, the milk is homogenised and clarified, removing foreign matter and standardising its microflora by centrifuging.

These steps are similar for both raw and pasteurised milk, although additional precautions must be taken for raw milk to ensure food safety.

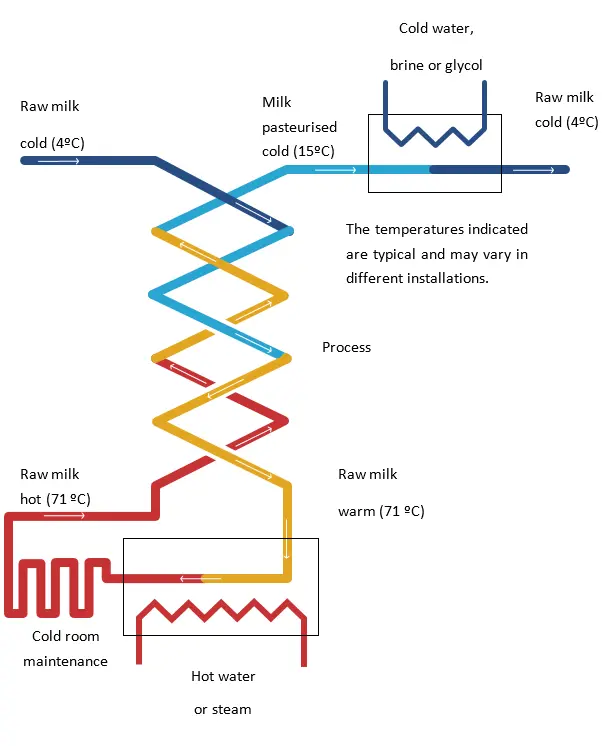

For cheeses made from pasteurised milk, pasteurisation is essential to eliminate germs and pathogens. Two methods are used: a slow method at 65 °C for 30 minutes and a fast method at 71 °C for 15-20 seconds. Pasteurisation is carried out with cross-flow heat exchangers to save energy and to avoid defective coagulation of calcium.

In summary, raw milk cheeses have a more intense flavour and require longer ripening time (more than 60 days) as they preserve beneficial micro-organisms. On the other hand, pasteurised milk cheeses can be consumed with less ripening time due to the elimination of pathogens, and can still achieve excellent quality.

Cheese production processes

The milk, either pasteurised or raw, is heated to 25-30 °C and ferments, moulds and/or flavourings are added. For coagulation, rennet is added, which acts on casein, the main protein in milk, causing enzymatic coagulation. Another option is acid coagulation, increasing the acidity of the milk to produce a “cut milk” appearance, typical in soft cheeses.

During enzymatic coagulation, the rennet breaks down the casein and forms a gel-like protein lattice. In acid coagulation, microorganisms produce lactic acid, changing the structure of the milk to a porous and fragile network. Cheeses can be made with enzymatic, acid or mixed fermentation, depending on the desired properties.

There are other stages during the cheese making process such as:

- Moulding and pressing.

- Turning.

- Salting.

- The airing

Refrigeration in the ripening process in cheese dryers

The last stage in the cheese-making process is maturing, also known as refining, drying or curing. It is at this stage where the cheese acquires its final properties and where it obtains that differentiating character provided by each manufacturer. This is where the smells, flavours, textures and even colours are refined. All the parameters that influence the identity of the cheese are provided here. This stage of production can take several hours or even several years, as in the case of the well-known Italian Parmiggiano Reggiano cheese.

The ripening of the cheese causes a series of changes in its physico-chemical properties which result in the cheese acquiring characteristics of texture, taste and smell, known as organoleptic properties. These changes are the result of the following reactions in the transformation of the milk and its olfactory, taste and textural characteristics:

- Glycolysis: this is the transformation of lactose into lactic acid.

- Proteolysis: This is the transformation of milk proteins.

- Lipolysis: This is the transformation of the fatty acids in milk.

How is this differentiation obtained?

By modifying the characteristics of the atmosphere created in the cheese drying rooms, such as temperature, humidity, air characteristics and, as mentioned above, the length of time the cheeses remain in the chamber. Normally, the higher the temperature of the chamber, the less time the cheeses remain in it and the greater the risk of deformation of the cheeses. The lower temperature is used for cheeses with a long ripening period and mainly for cheeses produced with raw milk.

We must distinguish between two different ways of carrying out the maturing process, depending on the fermentation process, whether enzymatic fermentation or acid fermentation.

Key factors of cheese dryers

- Temperature and humidity control: Allows to regulate the development of microorganisms and enzymatic reactions, impacting the flavour, texture and aroma of the cheese.

- Homogeneity: A uniform environment ensures consistent drying of all pieces.

- Accuracy: The ability to precisely adjust temperature and humidity is crucial to obtain specific results.

- Energy efficiency: Minimises energy consumption and optimises production costs.

Beneficios

- Improves cheese quality: Greater control over sensory characteristics and food safety.

- Reduces wastage: Minimises weight loss and mould formation.

- Optimises ripening time: Allows the process to be accelerated or slowed down as required.

- Flexibility: Allows the production of a wide variety of cheeses.

Tecnologías

Cheese dryers with temperature and humidity control: Autonomous or centralised systems that adjust the environmental conditions.

Defrosting systems: Ensure efficient and continuous operation.

Monitoring and control: Enable precise management of the drying process.

In summary, refrigeration in cheese dryers is a crucial technology for the production of high quality, safe and efficient cheese.

Thermohygrometric conditions in the ripening process

| Type of camera | Type of pasta | Temperature (°C) | Relative humidity (%) | Air velocity (m/s) |

| Cold room drying (or airing) | 12 – 18 °C | 65 – 80 % | At the outlet of the evaporator: max. 3 m/s, optimum 1-2 m/s. On the surface of the cheese: | |

| Soft dough and mouldy crust | 8 – 14 °C | 80 – 90 % | At the outlet of the evaporator: 0,5 a 1 | |

| Cold Room Maturation | Soft dough and washed rind | 8 – 14 °C | 90 – 95 %At the outlet of the evaporator: 0,5 a 1 | |

| Pressed pulp | 8 – 12 °C | >95 % | At the evaporator outlet: 0,2 | |

| Cold chamber | 2- 6 °C | >80 % | At the evaporator outlet: 0,2 |

Summary of parameters influencing ripening in cheese dryers

Humidity

It favours microbial development, which is greater in wetter curds. As a result, the drier ones ripen more slowly.

Temperature

It influences regulating microbial growth and also enzyme activity. Maximum enzyme production takes place at a temperature below the optimum temperature for microbial growth.

The optimal enzyme temperature is between 35 and 45 °C. Ripening takes place at lower temperatures and always depending on the type of cheese.

Salt concentration

Salt regulates the water activity and thus the curd flora. The usual salt content in cheese is 2 to 2.5 %.

Acidity

The pH conditions the microbial development, which also conditions the pH. The pH values of cheeses range between 4.9 and 5.5 in most cheeses, although those ripened by moulds are less acidic, and the pH can be close to 7.

Air velocity

The air speed increases the surface drying speed and in general a low speed is desirable for a good result.

Air renewal

Oxygen conditions the development of aerobic microbial flora, so that its contribution to the renewal favours the growth of moulds, yeasts and some proteolytic surface bacteria such as Brevibacterivum