Hot

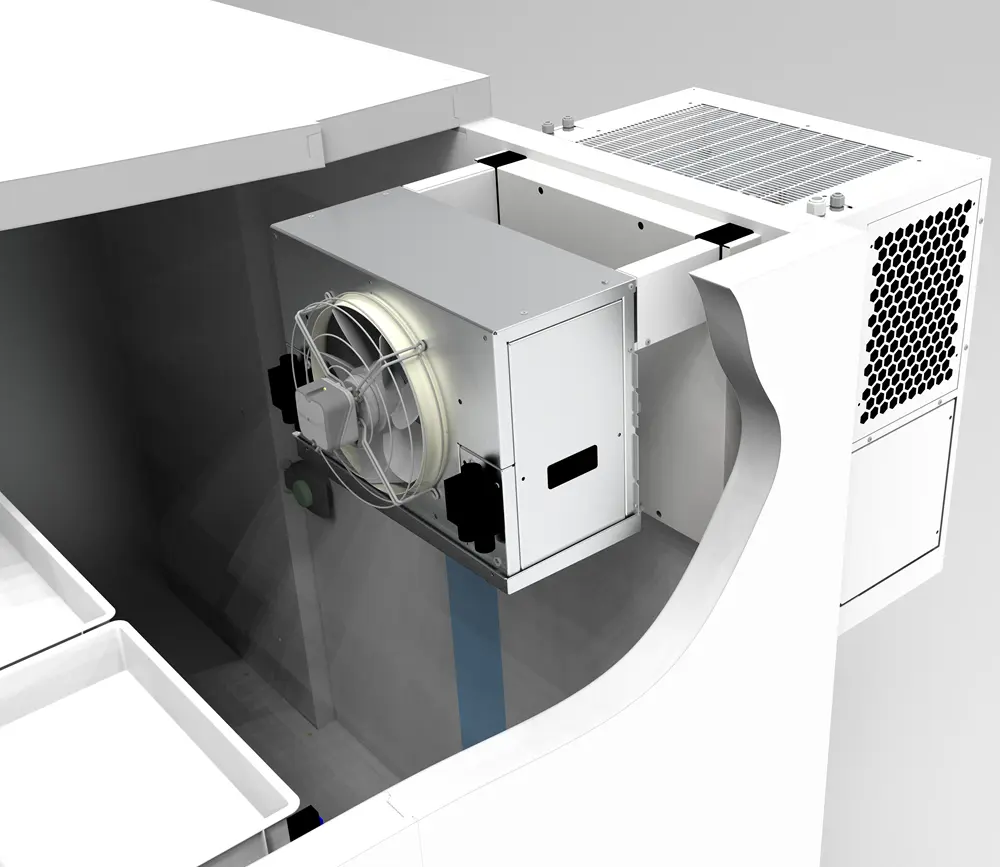

intarblock PRO R290

Compact refrigeration equipment

Compact units designed for mini refrigeration and wall freezers with R290.

- Description

- Technical features

- Optionals

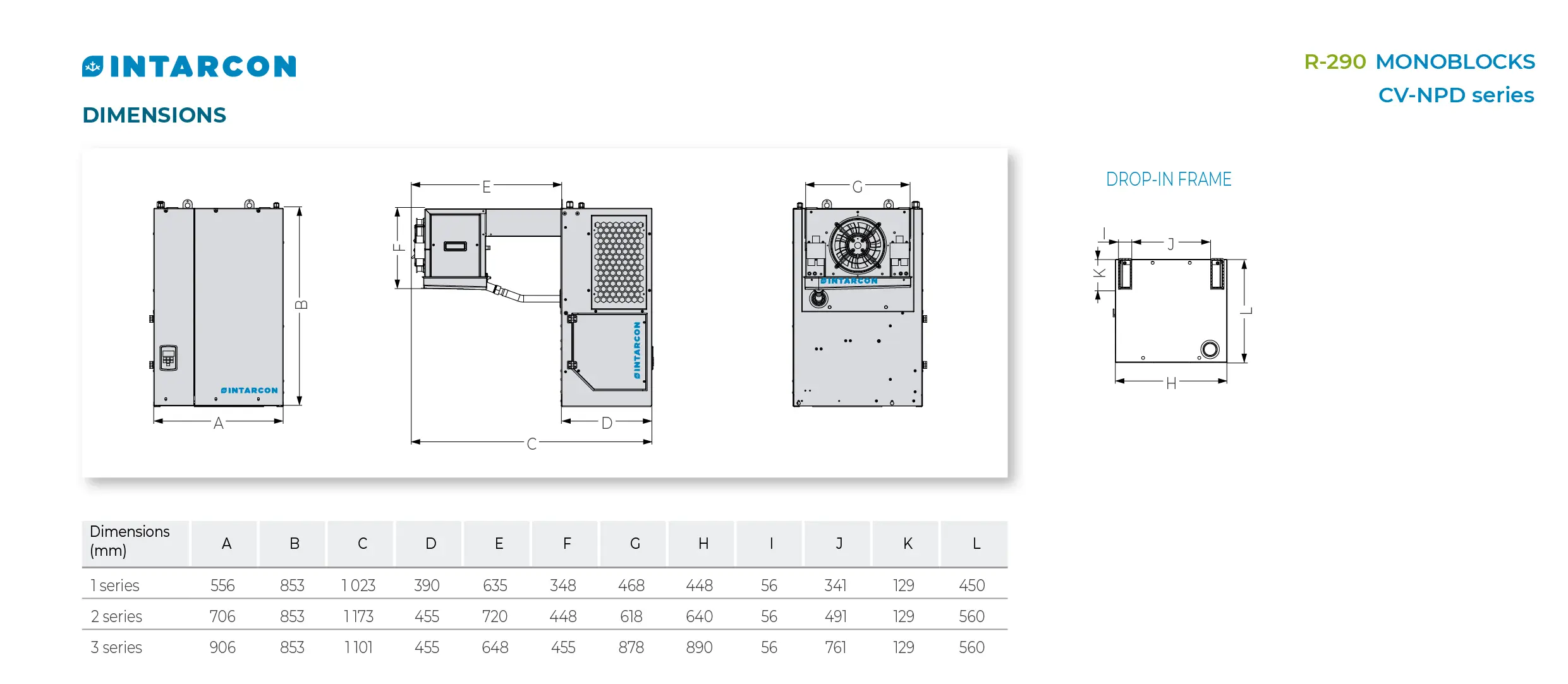

- Dimensions

- Documentación

Description

New pro wall-mounted compacts units R290 are designed by and for installers. For small and medium refrigeration and preservation cold rooms. Finished mounting on the wall of the cold room.

- Coils with protection: Tube and fin evaporator coil with cataphoresis treatment and microchannel condenser coil with polyester paint treatment.

- Electronic fans: Electronic fans with speed regulation in the condenser, reducing energy consumption as well as noise.

- Washable air filter: Accessible from the outside to avoid soiling of the condenser and the interior of the unit.

- Front register the removable of evaporator: Front panel with fans that can be access from the front of the equipment, to clean the coil and drain pan if the equipment is positioned between shelves. Ease of maintenance on all elements of the equipment.

- Hot gas defrost: Closes the liquid line, reducing defrost time and, consequently, with less start-up time and unit consumption.

- Electrical panel and Connectors: Electrical panel with front access. All protection and electronic control elements integrated. Terminal connection of the elements. All electrical elements use connectors that make them easy to replace.

- Drain pan: Condensate evaporation tray, accessible from the outdoor unit and removable. Made of stainless steel. Allows cleaning, as well as the evaporation coil. Overflow for driving.

Installation diagram.

Aluminum cubic type evaporator.

Aluminum provides better heat transfer than other materials, as well as optimum low temperature performance. The cubic type evaporators have a greater air range than the soffit type evaporators.

- R-290 refrigerant load.

- Independent refrigerant circuits per compressor.

- Hermetic compressors mounted on rails to reduce vibrations.

- Condensing coil in microchannel with polyester paint treatment.

- AC evaporator fans, and EC in condenser.

- High pressure switch.

- Stainless steel condensate tray, removable for cleaning, and stainless steel coil.

- Washable suction scren filtering mesh.

- Drainage resistance in self-regulating LT models.

- Drop-in frame mounting 80-150 mm.

- Access to electrical panel with hinged register.

- Hot gas defrosting.

- Thermostatic expansion valve.

- Aluminum plates covered with film for protection during transport in evaporator.

- Multifunction electronic control integrated in the unit.

- Cold room LED light

- Centrifugal fan with vertical impeller EC.

- Adaptation to bi-temperature.

- Water condensation. Inlet range +5 ºC / +50 ºC.

- Water condensation in the range -10 ºC / +5 ºC (only in LV models).

- Adaptation to equipment for outdoor installation.

- Halogen-free supply connection (5m).

- Male base and female schuko electrical connector base.

- Voltage control in single-phase models.

- Voltage control and phase failure in three-phase models.

- Power supply changeover to 230V 50 Hz in three-phase models.

- Drainage resistance (for chamber temperature < 0 °C in MV models).