Hot

R290 superblock

Industrial refrigeration compact units

Packaged refrigeration units for refrigerated storage designed for outdoor installation through a cold room wall

- Description

- Technical features

- Options

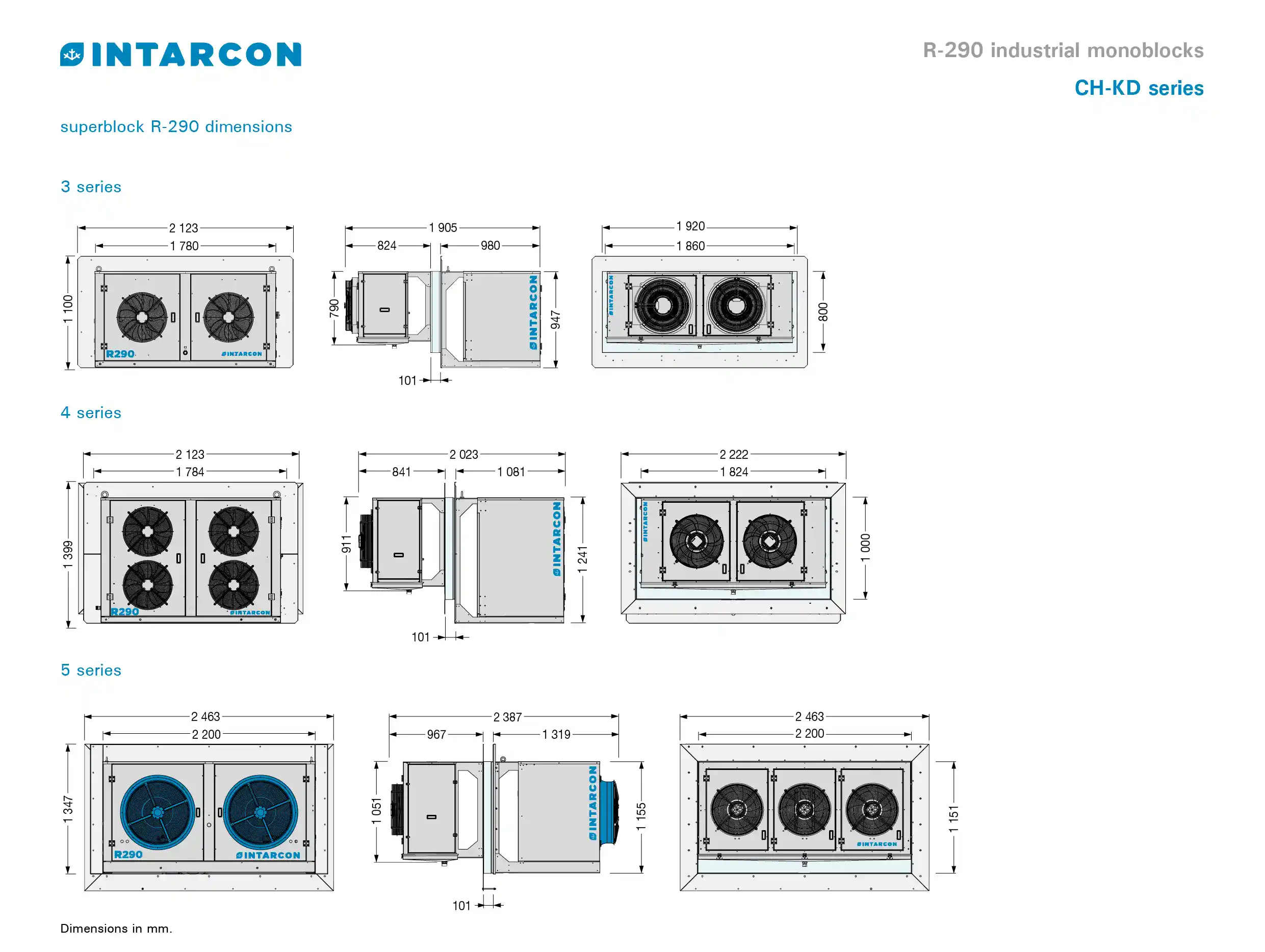

- Dimensions

- Documentation

Description

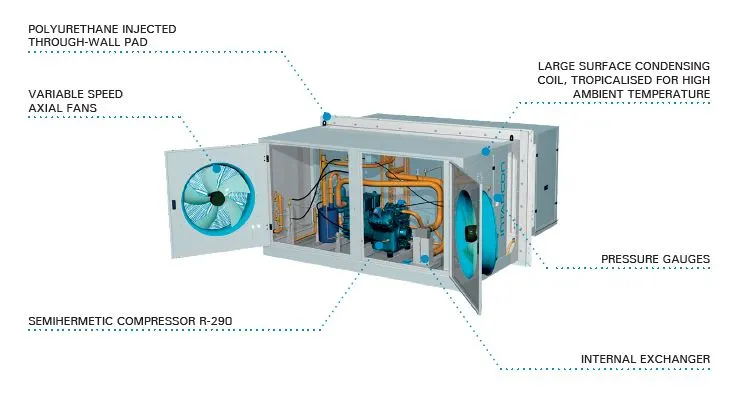

Compact industrial refrigeration equipment, manufactured in galvanised steel structure and bodywork with thermosetting polyester paint, designed for outdoor installation on the cold room wall, with easy maintenance access through hinged panels. These equipments are characterised by:

- Energy-efficient R-290 natural refrigerant.

- Tropicalised design for ambient temperature up to 45 ºC.

- 100 % factory tested.

- High cooling capacity in reduced volume.

Series:

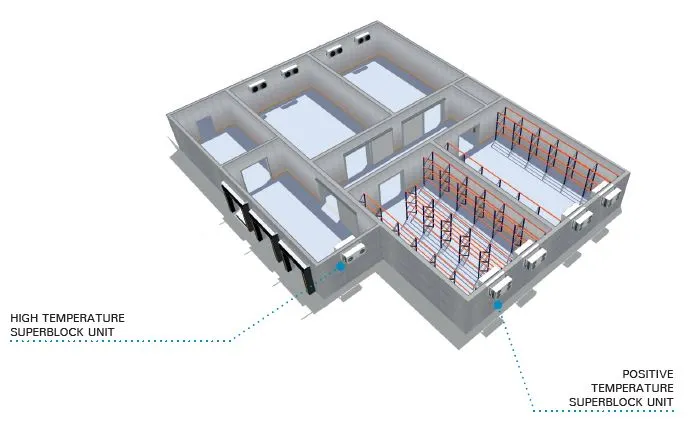

- ACH – High temperature (9 ºC…15 ºC) Monoblock units designed for high temperature application cold rooms, handling and process rooms, ante rooms and refrigerated loading docks.

- MCH – Positive temperature (-5 ºC…10 ºC) Monoblock units designed for preservation of generic products in medium temperature cold rooms.

- BCH – Low temperature (-30 ºC…-15 ºC) Monoblock units designed for preservation of frozen products in negative temperature cold rooms.

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Semihermetic reciprocating compressor, air flow, with discharge silencer, oil separator, mounted on dampers, with internal clixon and ATEX crankcase heater, multi-stage capacity control and unloaded start.

- Large area condensing coil, in copper pipes and aluminium fins, tropicalised for ambient temperature up to 45 ºC.

- High efficiency evaporating coil, in copper pipes and aluminium fins.

- Aluminium hinged condensate tray.

- Low-speed condenser motor fans, with internal electronic protection, mounted on nozzle, dynamically balanced blades and external protection grille.

- Proportional control of condensation temperature by fan speed control.

- Long-range evaporator axial motor fans, mounted on nozzles, dynamically balanced blades and external protection grille.

- Refrigeration circuit equipped with high and low pressure switches, ceramic dryer filter, sight glass and thermostatic expansion valve pre-adjusted at factory.

- Hot gas defrost for MCH and BCH series, and air defrost for ACH series.

- Heat exchanger for liquid subcooling and suction superheating.

- Independent IP55 electrical power and control panel, with thermal differential and magneto-thermal protection for compressor, fan(s) and heating elements.

- Multifunction electronic control with digital remote display.

- Mounting frame for panel mounting (4 and 5 series).

- Indoor/outdoor insulated panel injected polyurethane with 45 kg/m3 density.

Special features

- ACH – Air defrost and oversized condenser.

- MCH – Hot gas defrost and oversized evaporator to keep a relative humidity between 80 % and 85 %.

- BCH – Hot gas defrosting in coil and tray, and drain heater.

Depending on the series:

- ACH:

- Made-to-measure extension structure for through-wall assembly.

- Anti-corrosion coil coating.

- Mounting template for installation on insulation panel (included series 4 and 5).

- Protection system for voltage drops and phase failures.

- MCH:

- Made-to-measure extension structure for through-wall assembly.

- Anti-corrosion coil coating.

- Mounting template for installation on insulation panel (included series 4 and 5).

- Protection system for voltage drops and phase failures.

- BCH:

- Made-to-measure extension structure for through-wall assembly.

- Anti-corrosion coil coating.

- Mounting template for installation on insulation panel (included series 4 and 5).

- Protection system for voltage drops and phase failures.

- Bi-temperature. Equipment for medium and low temperature operation.