Superblock

Industrial refrigeration compact units

Packaged refrigeration units for refrigerated storage designed for outdoor installation through a cold room wall.

- Description

- Technical features

- Options

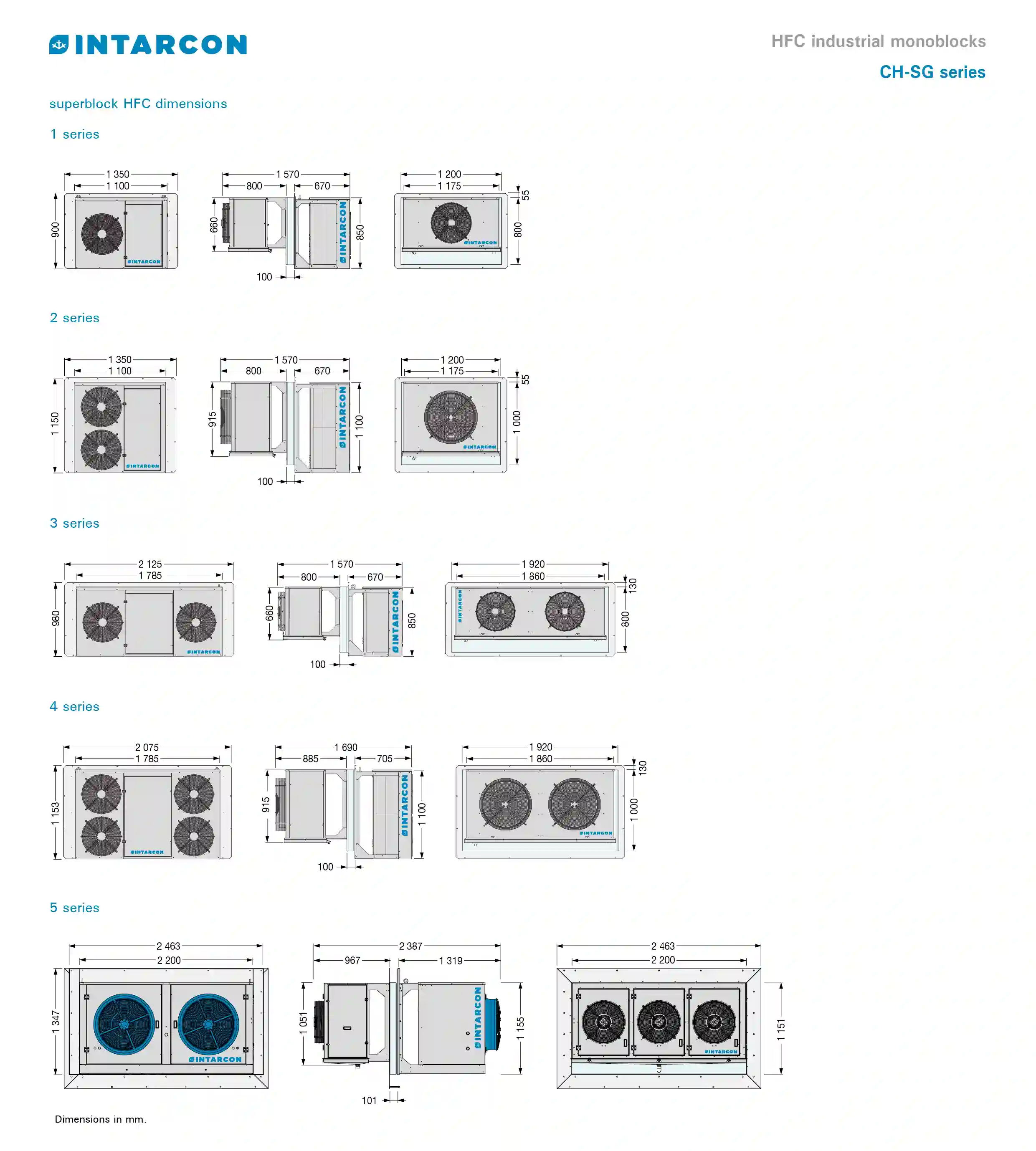

- Dimensions

- Documentation

Description

Refrigeration monoblock units built in a galvanised steel shell with polyester coating, designed for outdoor installation through a cold room wall, with easy maintenance access through thinged panels. These equipments are characterised by:

- High cooling capacity in reduced volume.

- Tropicalised design for ambient temperature up to 45 ºC.

- 100 % factory tested.

- Scroll compressors, with noise insulation.

Series:

- ACH – High temperature (9 ºC…15 ºC) Monoblock units designed for high temperature application cold rooms, handling and process rooms, ante rooms and refrigerated loading docks.

- MCH – Positive temperature (-5 ºC…10 ºC) Monoblock units designed for preservation of generic products in medium temperature cold rooms.

- BCH – Negative temperature (-30 ºC…-15 ºC) Monoblock units designed for preservation of frozen products in negative temperature cold rooms.

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Scroll compressors with noise insulation, mounted on shock absorbers, with internal klixon and crankcase heater.

- Large area condensing coil, in copper pipes and aluminium fins, tropicalised for ambient temperature up to 45 ºC.

- High efficiency evaporating coil, in copper pipes and aluminium fins.

- Low-speed condenser motor fans, with internal electronic protection, mounted on nozzle, dynamically balanced blades and external protection grille.

- Proportional control of condensation temperature by fan speed control.

- Long-range evaporator axial motor fans, mounted on nozzles, dynamically balanced blades and external protection grille.

- Refrigeration circuit equipped with high and negative pressure switches, ceramic dryer filter, sight glass and thermostatic expansion valve pre-adjusted at factory.

- Hot gas defrost for MCH, and BCH series, and air defrost for ACH series.

- Full control and power electric panel, with thermal and differential magneto-thermal protection for compressor/s, fan/s and heaters.

- Multifunctional electronic control with remote control keyboard.

- Mounting template for installation on insulation panel (4 and 5 series).

- Indoor/outdoor insulated panel injected polyurethane with 45 kg/m3 density.

- Liquid and vapour injection system for negative temperature models with R449A.

Special features

- ACH – High temperature (9 ºC…15 ºC): Air defrost and oversized condenser.

- MCH – Positive temperature (-5 ºC…10 ºC): Hot gas defrost and oversized evaporator to keep a relative humidity between 80 % and 85 %.

- BCH – Negative temperature (-30 ºC…-15 ºC): Hot gas defrost and oversized evaporator to keep a relative humidity around 95 %.

- ACH:

- Made-to-measure extension structure for through-wall assembly.

- Anti-corrosion coil coating.

- Mounting template for installation on insulation panel (included 4 and 5 series).

- Protection system for voltage drops and phase failures.

- Long range air streamer in evaporating fans.

- MCH:

- Made-to-measure extension structure for through-wall assembly.

- Anti-corrosion coil coating.

- Mounting template for installation on insulation panel (included 4 and 5 series).

- Protection system for voltage drops and phase failures.

- Long range air streamer in evaporating fans.

- BCH:

- Made-to-measure extension structure for through-wall assembly.

- Anti-corrosion coil coating.

- Mounting template for installation on insulation panel (included 4 and 5 series).

- Protection system for voltage drops and phase failures.

- Long range air streamer in evaporating fans.

- Bi-temperature. Equipment for medium and low temperature operation (except 15 and

30 HP models).