intarCUBE A2L approved

Compact condensing unit

Ultra-compact, sound-insulated condensing unit with progressive capacity control for commercial refrigeration.

- Description

- Technical features

- Options

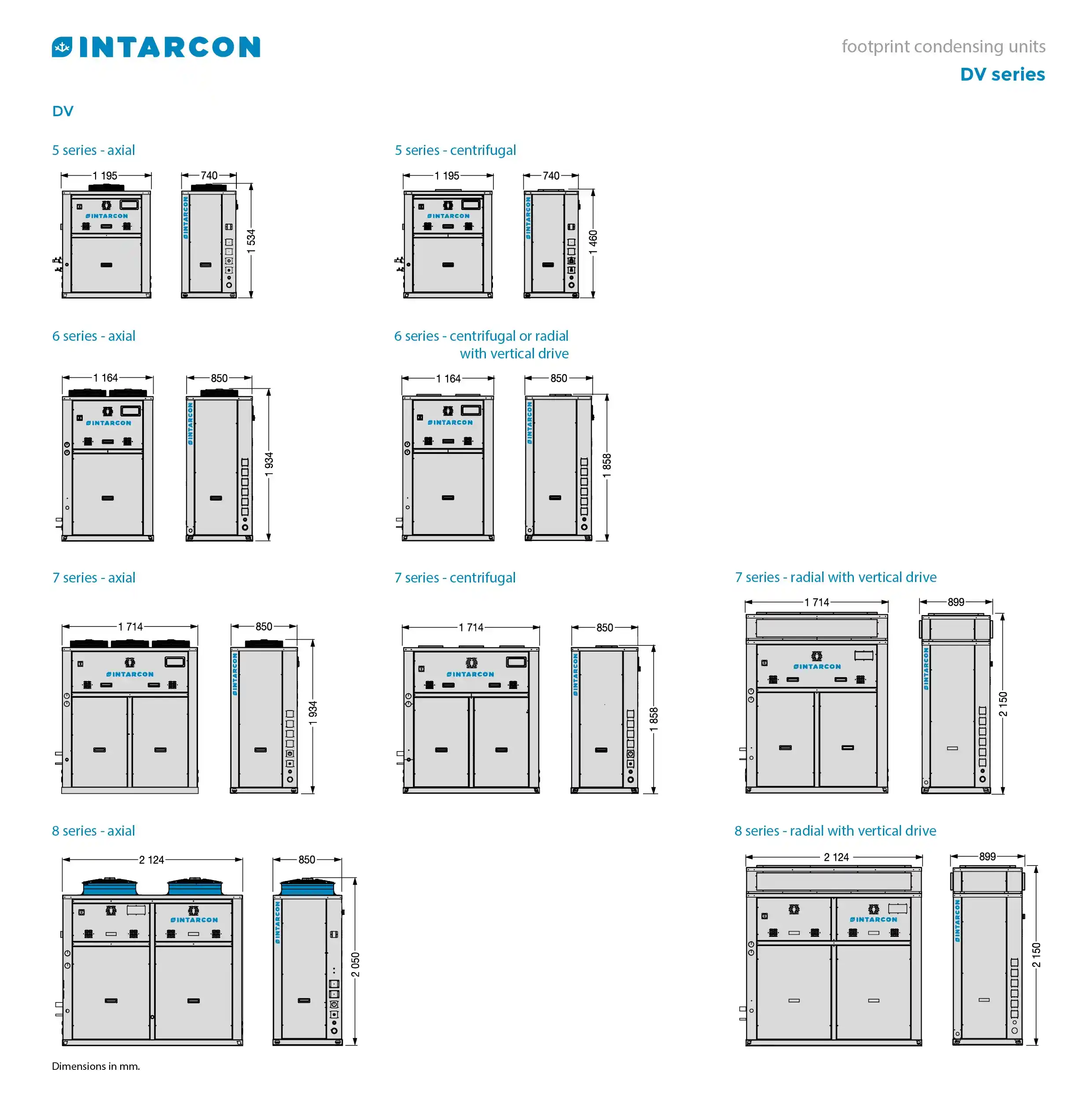

- Dimensions

- Documentation

Description

intarCUBE A2L Approved condensing units has been designed for medium capacity centralised commercial refrigeration applications, equipped with semi-hermetic compressors and designed to operate with either R-449A refrigerant or low GWP (< 150) slightly flammable R-454C refrigerant. The new intarCUBE A2L approved condensing units are positioned as an efficient and safe, low-cost investment, becoming a very good alternative to comply with the medium-term regulatory framework on fluorinated gases in the European Union. These equipments are characterised by:

- A2L certified units.

- R-449A and R-454C refrigerants.

- Free of F-Gas tax (R-454C).

- F-Gas 2022 and Ecodesign compliant.

- 400V 3N 50Hz power supply. Available in 60 Hz. Other voltages by request.

- Semi-hermetic Bitzer Ecoline compressors, with rotalock service valves, mounted on dampers, with crankcase resistance.

- Compressor compartment with safety ventilation against the risk of explosive atmospheres.

- Condenser coil with copper pipes and aluminium fins, with air circuit separated from the compressor compartment.

- Axial or EC radial condensation fans, with independent air volumes

- Refrigeration circuit equipped with high and low pressure switches, ceramic dryer filter, liquid receiver and sight glass.

- Individualised electronic oil injection system per compressor (on 2-compressor models)

- Full control panel integrated in the unit, with differential, MCB protection for compressors and fans.

- Certification of the condensing unit as a whole (Ecodesign, pressure equipment, etc.).

- CRII capacity control system on compressor.

- Anti-corrosion coating of condenser coil.

- Automatic emergency manoeuvre.

- Low voltage and phase change protection.

- Heat recovery (20 or 80 % condenser heat) for hot water generation.

- Safety system for monitoring the risk of explosive atmospheres, for installation in machinery rooms.