Industrial cubic type

- Description

- Technical features

- Options

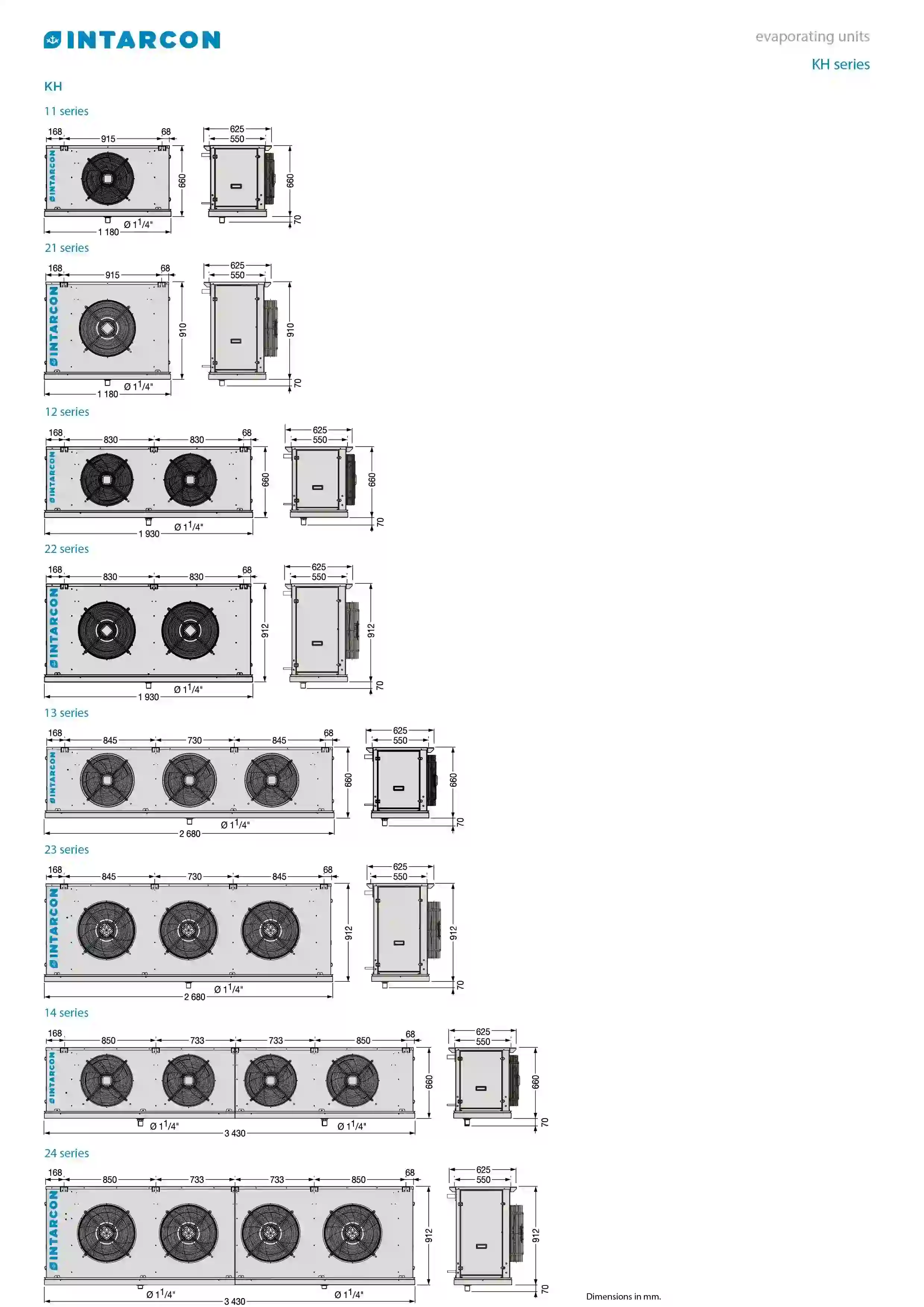

- Dimensions

- Documentation

Description

Industrial cubic type evaporating units, with built-in control valves and control board, for positive, negative and high temperature cold rooms, built in galvanised steel structure and bodywork with thermosetting polyester coating. These equipments are characterised by :

- High efficiency coils.

- Expansion and solenoid valves, and suction siphon integrated.

- 100 % factory tested and adjusted units for the highest performance.

- Double condensed liquid pan, insulated in low temperature models.

- 400V 3N 50Hz power supply. Available in 60 Hz. Other voltages on request.

- Air defrost.

- Air-cooled high efficiency coils, in copper pipes and aluminium fins, with 4, 5, 7 and 10 mm fin spacing.

- Double stainless steel draining pan and insulation for negative temperature.

- Built-in solenoid valve in liquid line and thermostatic expansion valve.

- High-flow axial motor fans operating at 1300 rpm.

- Ready-to-solder refrigeration connections, with built-in suction oil trap.

- Flexible drain pipe heater (only for negative temperature models).

- Electrical defrost heater inside the coil and over the drain pan.

- Hot gas defrosting.

- Electrical expansion valve.

- Control and power panel with electronic microcontroller and digital display, with differential protection MCB switch for heaters and fans, 6 relays for control, cold room and defrost temperature probes, and operation LEDs.

- Built-in humidification / deshumidification / heating kit.

- Anti-corrosion coil coating.

- Long range air stream fan.

- Fan collar heater.

- ATEX fans.

- Textile ducts Warm-up.