Low charge R717 refrigeration

INTARCON2022-11-11T09:55:08+01:00Introduction

Technological progress in refrigeration in recent years has focused on a number of well-known strategies, such as energy efficiency, the use of natural refrigerants, in this case with low-charge R717, and the integration or prefabrication of systems.

In addition to the fight against climate change, there is another important driver behind these strategies, which we have recently become more aware of than ever, and that is the scarcity of natural resources: energy and materials. This is why it is so important in the coming years to focus on these strategies: energy efficiency, natural refrigerants and optimisation of systems.

One of the natural consequences of these strategies is the reduction of the refrigerant charge of the systems, either due to a reduction of the greenhouse effect of fluorinated refrigerants, or due to safety criteria for natural refrigerants, flammable or toxic as in the case of propane and ammonia respectively.

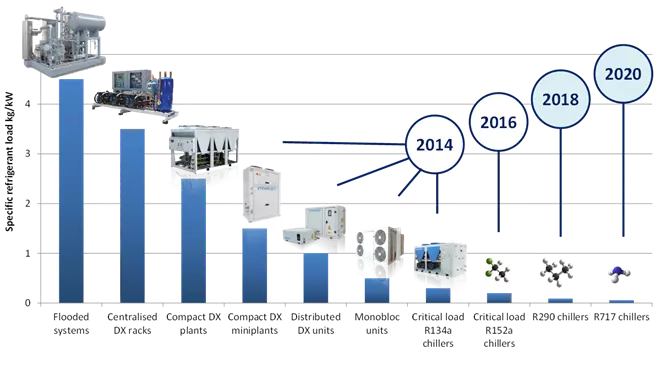

At Intarcon we have seen how, since we started our business 15 years ago, the refrigerant charge of the systems has been reduced with each new development: from overfeed ammonia systems to the most innovative critical load chillers, through a large number of increasingly compact systems. The charge reduction between the two extremes is more than 50 times for the same cooling capacity, that’s to say, less than 2% of the original charge.

Low-charge R717

The question is, what is the definition of low charge for ammonia?

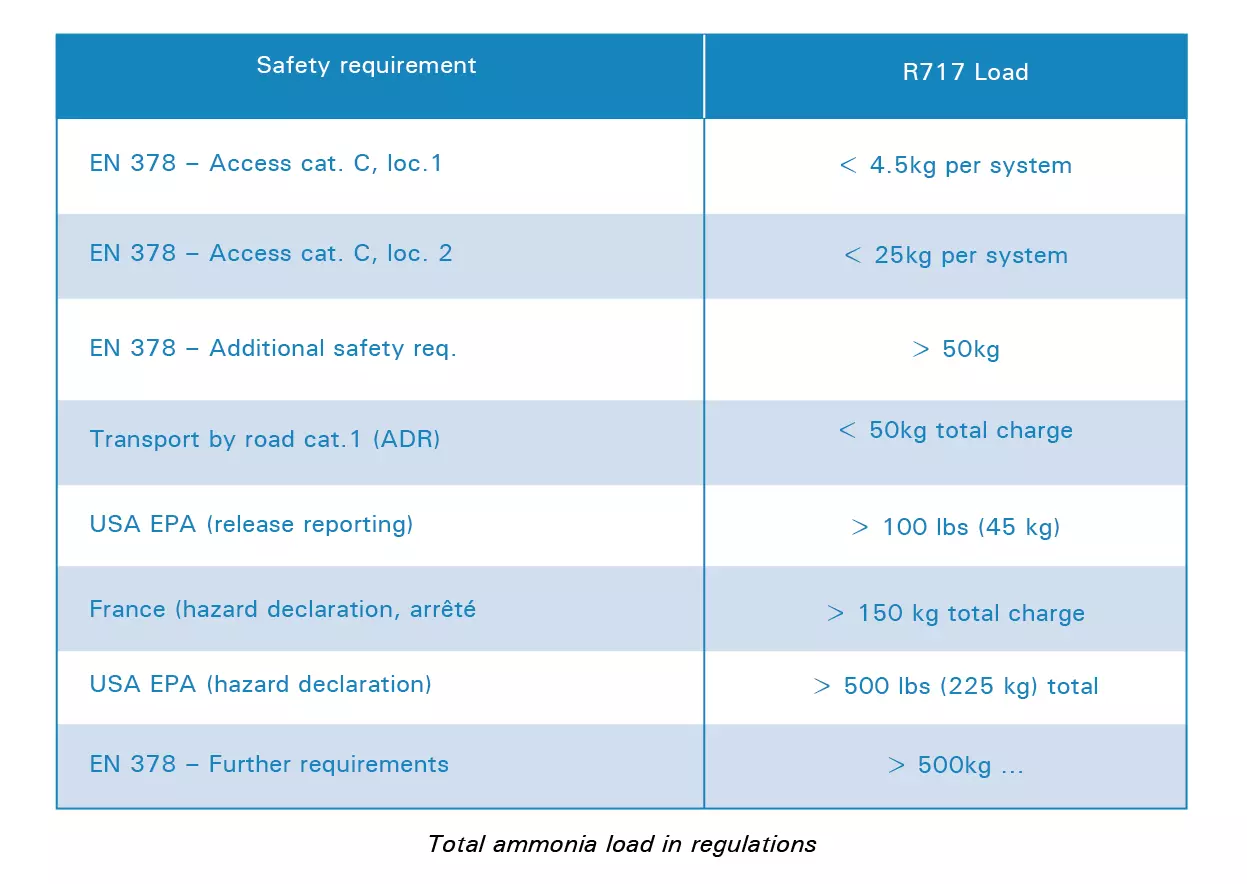

On one hand we have the regulations. In the United States, following certain accidents at ammonia facilities, Health and Safety and environmental risk thresholds were established based on the ammonia content of the facility, such as the value of 500 lbs (225 kg) above which the facility is required to register the hazard with the EPA.

In Europe there is no similar common regulation in this respect, but some countries such as France do have a similar policy (e.g. from 150kg an environmental risk declaration is required). Other safety standards such as EN 378, for the design of refrigeration systems, do set safety requirements depending on the refrigerant charge of each circuit. There are some other regulations setting load thresholds for ammonia, such as the European road transport regulation (ADR), which would require a special transport above 50kg of ammonia.

So, from a regulatory point of view, there is no clear criterion for what constitutes a low-charge R717, although for example here in Europe, less than 50kg of ammonia has great advantages. You can make pre-charged systems that are transported by road and the safety requirements in the design are lower.

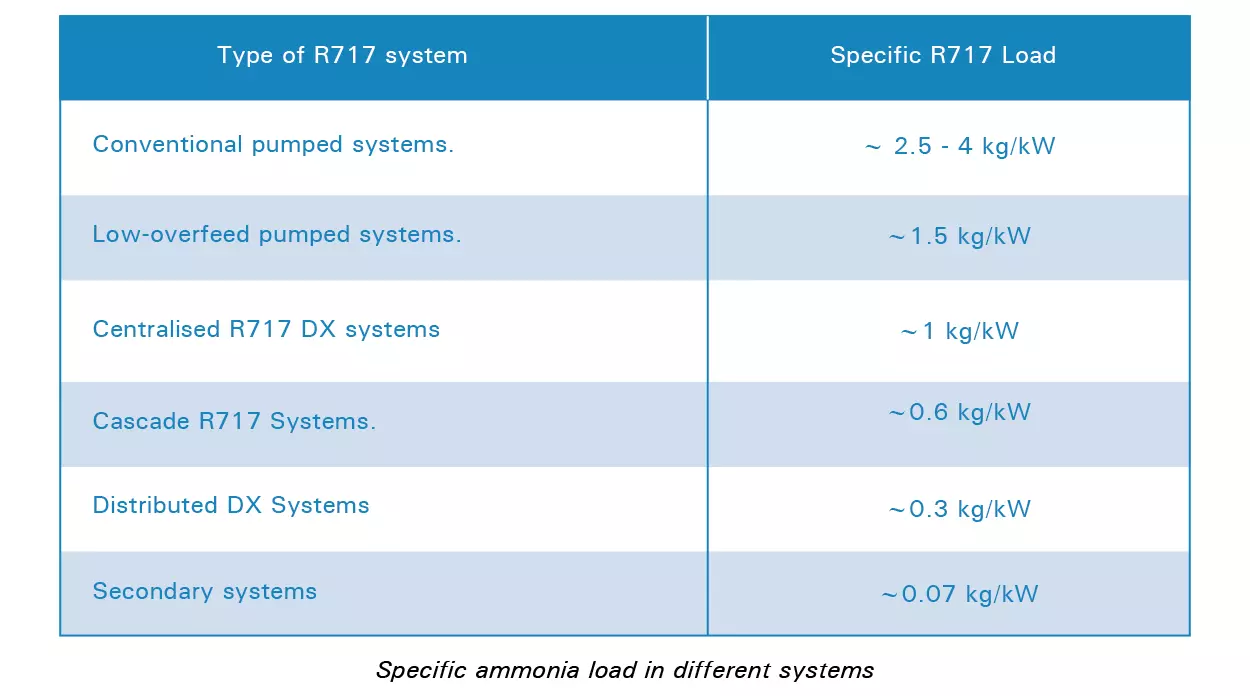

From another point of view, if we analyse the technical literature, we will see that the concept of low-charge R717 differs between different authors and between different technical practices in different countries. In the United States, flooded ammonia systems with a low overfeed rate are referred to as low charge, with a specific charge of around 1.5 kg/kW; while in Australia, centralised direct expansion ammonia systems are referred to as low charge, with a specific load of around 1 kg/kW. In Europe we usually refer to secondary systems, with a specific charge of even less than 100 g/kW, or to distributed direct expansion systems with a specific charge around 0.3 kg/kW.

Low-charge R717 technology

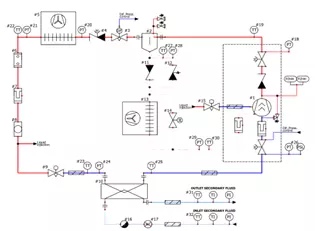

Let me begin by discussing the latter system, distributed DX. In contrast to centralised DX systems, in which parallel compressors serves multiple services, in the distributed DX system we would have a number of condensing units serving one or a few services.

This distributed installation concept not only allows to split the refrigerant charge, but the design of the plant itself also allows to reduce the charge. This is an example of the technology we have used in the Ammolite DX condensing units:

- Microchannel condensers for direct condensation of ammonia with dry air. That is, without adiabatic effect and without water consumption.

- Semi-hermetic screw compressors with variable speed permanent magnet motor, with economiser for low temperature.

- Tube and fin evaporators, direct expansion, dry expansion, with electronic expansion valve controlled by superheat.

- Direct oil cooling by air.

- Heat recovery for production of hot defrost glycol.

- Miscible oil.

It should be noted that this system requires a high-pressure liquid receiver, although a small one.

Similarly in air-cooled low-charge ammonia chillers, the technology is mostly the same, but there are some differences:

– The stainless steel plate evaporator

– The critical load design, without liquid receiver.

Key aspects of R717 DX systems:

DX evaporators, e.g. tube and fin evaporators, require a suitable refrigerant distribution design adapted to the low mass flow rates of ammonia (compared to other refrigerants) at a higher speed to counteract the increased tendency of ammonia to flow stratification. This is due to the large density difference between liquid and vapour. For the same reason, tubes with an enhanced exchange surface are often used to promote complete wetting of the tube. These in turn are very susceptible to oil fouling (in case of non-miscible oil).

A DX ammonia evaporator equipped with an electronic valve can operate adequately with a DT1 of 6 or 7K.

In low-charge R717 or ammonia systems no residual refrigerant leakage is permissible. This makes it necessary to use semi-hermetic compressors with high-efficiency gas-cooled motors.

Direct expansion systems also need to ensure subcooling in the expansion valves and avoid flash-gas in the liquid lines, which is achieved by the economiser or subcooler.

On the other hand, there is the water content in the ammonia, which is very detrimental to the operation of direct expansion evaporators. Any presence of water in the system prevents complete evaporation of the ammonia in the evaporator, leaving a residual solution of ammonia and water at 20%. There are various systems for removing the water, such as distillation, but in our case we use the oil itself.

The oil is a key aspect of the Ammolite system. Despite separation systems, there is always some oil migrating to the evaporator and must be returned to the compressor. An oil that is miscible at evaporator operating pressures and temperatures is diluted in the refrigerant liquid throughout the evaporator, and eventually returns to the compressor with a refrigerant content of between 10% and 20% which significantly reduces its viscosity. Thanks to this good oil return to the compressor, the oil separation system is simplified and there is no need for oil purging systems or maintenance.

The direct cooling of the oil compared to thermosyphon systems results in higher efficiency, lower refrigerant charge and simpler control.

Finally, the high hygroscopicity of PAG oil by trapping water molecules in its polymeric chain guarantees moisture-free operation in the circuit.

Ammolite range construction

The integration of all this technology in a compact construction is what gives rise to the Ammolite product range. Both the chillers and the air-condensing units are characterised by their modular V-shaped condensers.

Dry microchannel condensers are a key element in the Ammolite concept. It is often argued that evaporative condensing allows a reduction in energy consumption, but without considering the enormous water consumption involved (approx. 3 m3/h per cooling kW) and the cost of treated water (approx. 2 Euro per m3).

The following example corresponds to a 720kW chiller delivering glycol at -8ºC in a meat industry in Mataró (Barcelona). It has two independent refrigerant circuits with an ammonia charge of 25kg per circuit.

Ammolite also offers glycol chillers down to glycol outlet temperatures of -30ºC. At low temperatures, however, secondary systems have certain disadvantages, and this is where direct ammonia expansion is more advantageous.

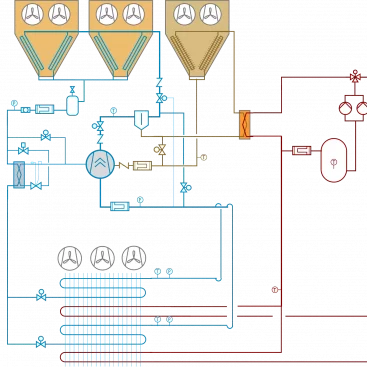

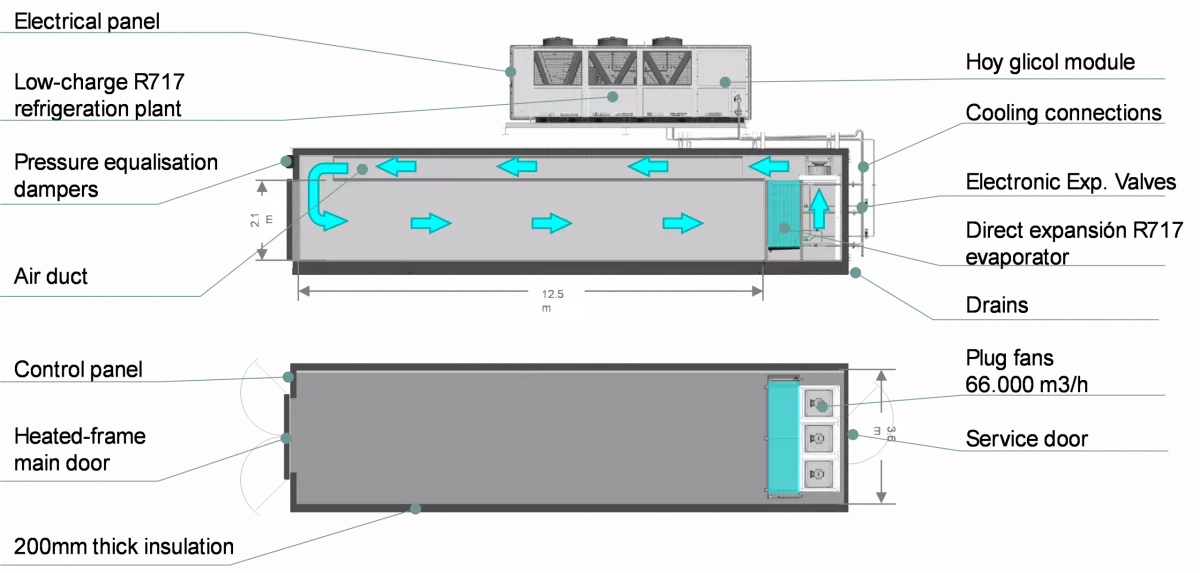

The condensing units pictured here corresponds to two independent DX systems with tube and fin evaporators in two blast-freezing tunnels. They are installed in a slaughterhouse in Tarancón (Cuenca). Each system has a total load of 50kg of ammonia for a cooling capacity of 120kW at -35ºC evaporation.

These DX systems have been new for less than a year. A more detailed view of the blast-freezing tunnel is shown in the following diagram. The assembly is called “Turbofreezer” because of the three high-pressure turbines that force the air through the meat load. The DX evaporator has a double refrigerant circuit and a hot glycol defrost circuit produced by heat recovery from the oil.

The entire installation is monitored by the kiconex system, which is connected to the cloud and allows real-time visualisation of operation.

The blast-freezing process lasts about 24 hours and has an energy cost of about 0.1 kWh per kg of meat, approximately one third of the consumption of other R448A tunnels operated by the same owner.

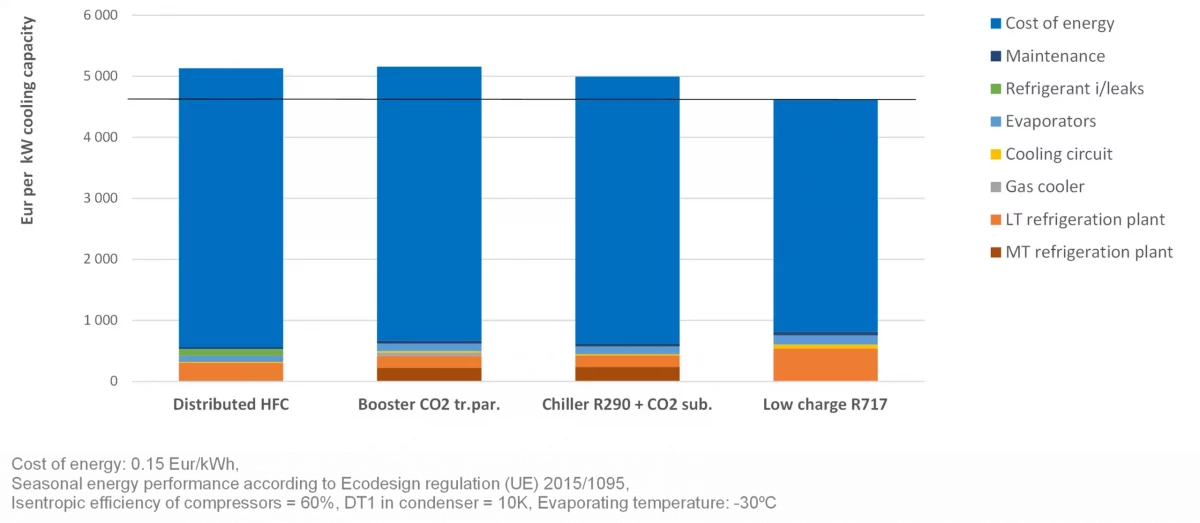

This low-charge R717 or ammonia direct expansion system is applicable to low temperature cold rooms, and for this purpose we developed the following life cycle cost analysis of the low charge system compared to other refrigerants (R449A, transcritical CO2, and R290-CO2 cascade).

The study over a 15-year life span shows how, despite the higher capital expenditure, the ammonia direct expansion system results in a lower life cycle cost due to the lower energy consumption, and thus lower operational expenditure.

Conclussion

In conclusion, this low-ammonia technology is characterised by the following advantages and benefits:

- It is an environmentally friendly solution, with no direct effect on global warming, and with minimal total equivalent warming impact due to the higher energy efficiency.

- Increased safety and reliability, thanks to the minimal ammonia charge.

- Easy and quick installation thanks to the plug & play concept.

- Equipped with the latest digital technology such as the kiconex cloud monitoring system.

- Rapid pay-back of the over expenditure compared to competitive technologies with lower initial capital cost. This is thanks to the optimal life-cycle cost.

Finally, it is important to keep in mind the initial thinking on the challenges we face in the coming years and decades. We are not only committed to reducing our impact on the environment with efficient systems, with low-energy demand and low-greenhouse effect. The new global situation we are facing will also lead us to economise on natural resources: reducing water consumption and optimising the use of materials through increasingly compact and optimised systems.