Industrial or commercial refrigeration compressors

INTARCON2022-07-20T11:07:17+02:00Industrial or commercial refrigeration compressors are the fundamental part of the equipment and systems responsible for supplying and satisfying the refrigeration needs of a specific space, chamber, process…

Compressors: the core of refrigeration systems

What is a refrigeration compressor?

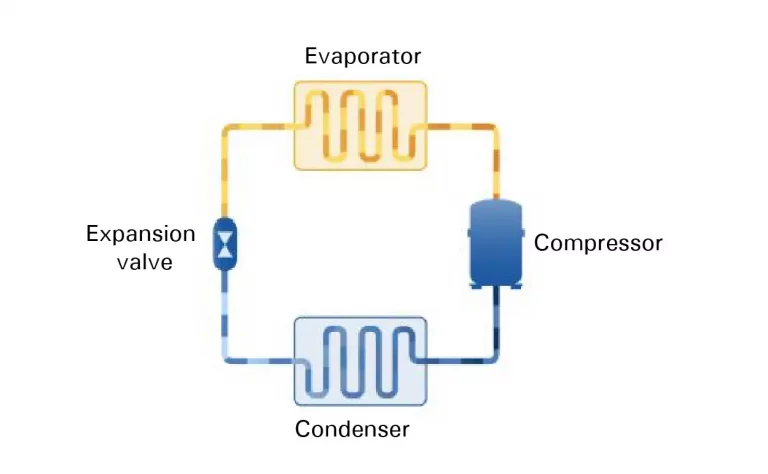

The compressor is the main component of refrigeration equipment, its function is to compress the refrigerant gas or fluid, thus allowing pressure changes to occur in the refrigerant gas or fluid, causing it to move along the refrigerant circuit.These changes in pressure and temperature along the refrigerant circuit lead to changes in the state of the refrigerant gas or fluid as it passes through the condenser, expansion valve and evaporator. With these changes in conditions, the refrigeration process takes place in a basic refrigeration circuit. The compressor is thus responsible for the refrigerant or refrigerant fluid to run through the entire refrigeration circuit, increasing the pressure and temperature of the refrigerant, causing the other elements to change state.

Compressor operation is identical in both commercial and industrial applications, the only difference between the two could be the size of the compressors used and the types of compressors depending on the refrigeration equipment selected. Similarly, the compressor power will depend on the refrigeration field, which can be commercial or industrial.

What is the function of an industrial or commercial refrigeration compressor?

- This is the component that transports the refrigerant gas through the refrigerant circuit.

- The compressor has the function of compressing the refrigerant coming in from the suction side and pushing it to high pressure and temperature.

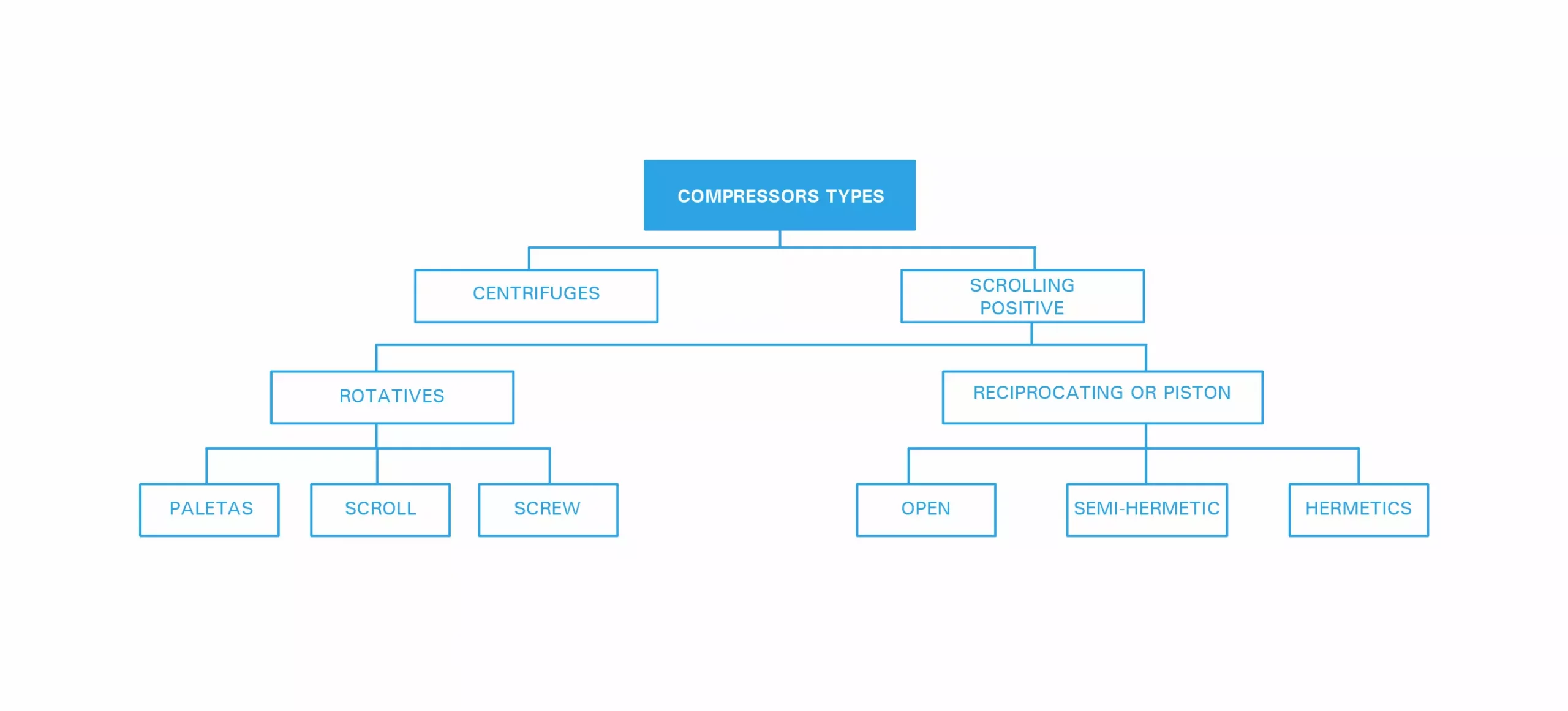

Types of refrigeration compressors

For a correct classification of the types of compressors for both industrial and commercial refrigeration and their basic operation, we must take into account two main criteria that differentiate the type of compressor, these are its compression technology and its structure. Although in a general way the classification of compressor types is based on:

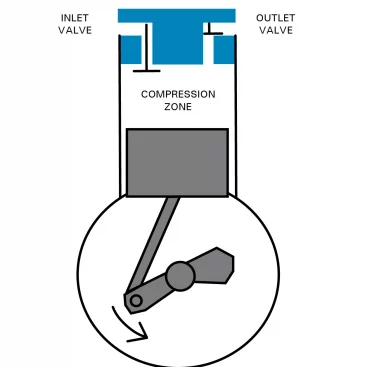

Reciprocating or piston compressors.

The refrigerant is compressed inside a cylinder thanks to the reciprocating motion of a piston by means of a crankshaft driven by an electric motor. This type of compressor is characterised by:

- They have inlet and exhaust valves that allow a more constant flow.

- The use of silent-block, in order to mitigate the high vibrations to which this type of compressor is subjected.

- Oil level sight glass and crankcase resistance.

- Connection for oil balancing.

- Possibility of individual, tandem, trio or rack mounting.

Hermetic. They are used in small commercial applications and are characterised by the fact that their structure is covered by a single casing containing both the compressor and the drive motor, which is totally sealed, thus preventing possible refrigerant leakage. However, as a result of the contact between the components and the drive motor, refrigerants such as ammonia cannot be used which could damage the materials of which it is composed. They also have the disadvantage that they cannot be repaired in the event of a breakdown.

- Semi-hermetic. Their application is mainly commercial and their construction has two independent housings so that we would have access to the maintenance and repair of the compressor. However, there is also contact between the motor and the refrigerant fluid, so certain refrigerants cannot be used and there is a higher risk of leakage.

- Open. Their structure divides the motor and compressor into two independent modules, linked by a mechanical transmission. They stand out for their total accessibility for repair and maintenance, also admitting any refrigerant fluid and avoiding the overheating of vapours before admission to the cylinder. On the other hand, they present a higher risk of leakage.

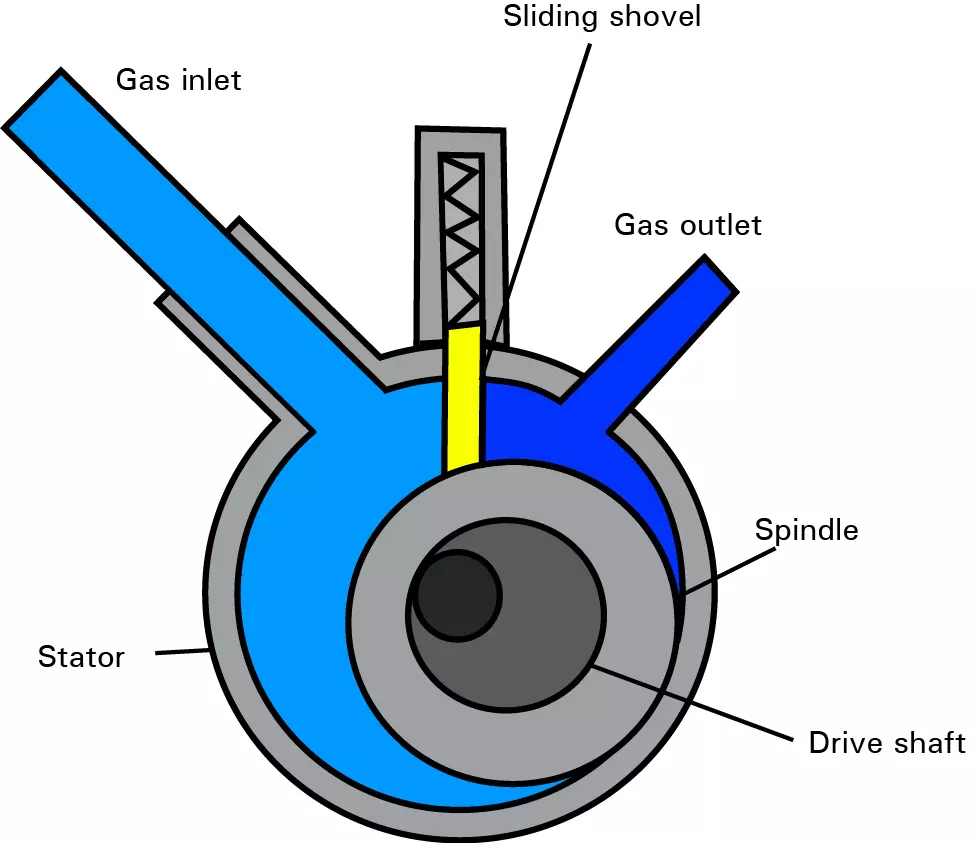

Rotary compressors.

They are characterised by a continuous compression flow, as they do not have suction valves. In addition, oil plays an important role in this type of compressor, as it is responsible for lubrication and sealing. Several types can be distinguished according to the type of rotor movement, although the most common ones:

Paletas or Vane. The refrigerant fluid fills the space between the compressor rotor and stator, driving the movement of the motor shaft. The fluid is compressed as its space decreases at the point of minimum diameter inside the compressor. This type of compressor has a spring-loaded vane located in a slot in the cylinder. This spring is responsible for dividing the suction phase and the discharge chamber of the compressor.

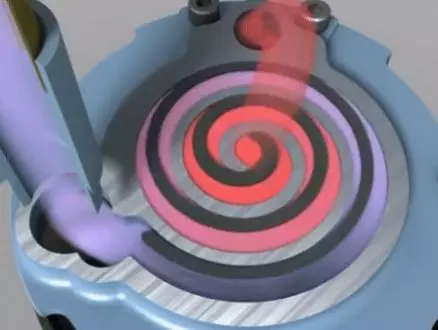

- Scroll. Its operation is based on the orbital movement of a spiral. It is therefore formed by two identical spirals, one of which is top and fixed (stator), in the centre of which the exhaust port is located. As the lower spiral (rotor) orbits inside the fixed spiral (stator), the thrust of the fluid pockets with the walls causes it to move inwards and subsequently increase its pressure.

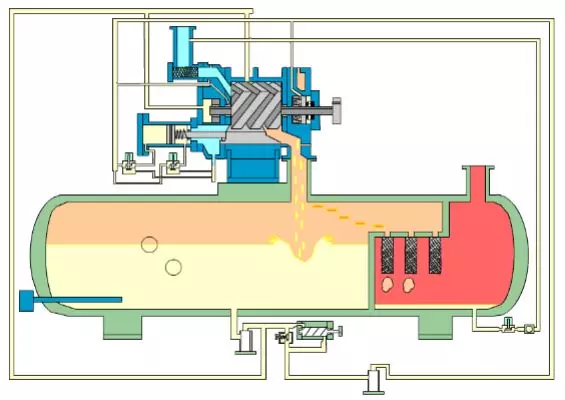

Screw type. It is used for medium and high power ranges, and its application is industrial. It is made up of two rotors of conjugated profiles, one of which, called “male” and which is coupled to the electric motor, forms lobes, while the other “female” has alveoli. Their regulation capacity ranges from 10 to 100%, thanks to a part called a slide, which opens or closes the opening of the fluid to the rotors to vary the power. These compressors are lubricated by direct injection of oil at a controlled temperature, also providing sealing and absorbing the heat of compression. They also have an oil separator and oil injection control.

Energy efficiency – Industrial refrigeration compressors.

When we talk about the compressor, we are referring to the core of a refrigeration system, so it is important that we talk about its energy efficiency and the different alternatives that exist.

The screw compressor is currently the most widely used type of compressor in industrial refrigeration, although the reciprocating or piston compressor was once the most widely used. The reasons for this change are:

- It is possible to achieve more cooling capacity with a single screw than with a reciprocating compressor, which results in a higher cooling capacity than with a reciprocating compressor:

- Although the screw compressor has a higher cost, above certain capacities, we will only need one screw compressor as opposed to several alternatives, where the initial cost and the maintenance cost would be higher.

- With the screw compressor it is possible to operate in single-stage operation from lower evaporating temperatures, thus presenting a higher compression ratio.

- It is possible to approximate a double-stage operation with a single screw compressor.

- Maintenance of the screw compressor is lower.

- Screw compressors exhibit less vibration due to the fact that they are not unbalanced, in contrast to reciprocating compressors.

Nevertheless, the piston compressor is once again a viable alternative in the industrial refrigeration sector, as it is more efficient than the screw compressor both at full and part load.

Compressor selection considerations

Now that we are familiar with the most important general aspects of industrial and commercial refrigeration compressors, we must take into account them in order to make the right choice:

- Cooling capacity of the system, depending on the operating conditions:

- Minimum condensing temperature: this would affect the lubrication of the compressor.

- Maximum evaporation temperature: would affect high mass flow rate, excessive force on bearings, connecting rods…

- Maximum condensing temperature: this would affect the maximum compressor pressure.

- Low evaporating temperature: would affect insufficient cooling of the engine due to low gas density.

- Límite térmico: afectaría a la temperatura de descarga demasiado alta.

- Dimensioning of equipment.

- Noise level.