What is the right equipment for a cold room?

INTARCON2024-12-11T13:57:42+01:00It is very important not to make a mistake in the choice of refrigeration equipment for a cold room, as the optimal functioning and preservation of our products will depend on it.

Types of cold rooms

There are various types of cold rooms depending on their application, size or configuration.

Application

Depending on their application, cold rooms can be used as working rooms, pre-cooling rooms, product preservation rooms or freezing rooms. Depending on the type of product to be preserved, the cold room will have certain climatic conditions, temperature and humidity controlled so that the product does not lose its properties. In general, if we differentiate cold rooms according to the operating temperature range, we find high, medium and low temperature cold rooms, and freezing cold rooms.

Size

If we differentiate the cold room according to its size, we find small, medium and large cold rooms.

Configuration or construction

If we differentiate them according to the type of construction, we find insulated and non-insulated cold rooms, with or without insulation on the floor. We can also talk about modular cold rooms, built or industrial panels.

Which equipment is appropriate for which cold room?

Depending on the application or the operating temperature range of the cold room, we have: high and medium temperature cold rooms to preserve fresh products between 0 and 18ºC; low temperature or negative temperature cold rooms to preserve products between -28º and 0ºC; and freezing tunnels with temperatures of -30ºC.

Refrigeration equipment for high temperature rooms.

For small and medium sized cold rooms and for product preservation applications between 8 and 18 ºC, split or semi-compact systems are available in silent or vertical construction, with dual flow evaporation unit that allows air circulation in the room without directly influencing the product. These units are available with compressors of between ½ and 10 HP with a cooling capacity of between 1.5 and 17 kW.

For larger cold rooms, the solution would be based on water, glycol or brine chillers with a low charge of R290 refrigerant for industrial applications. These chillers can integrate the hydraulic unit, being a Plug & Play system that provides high efficiency to the installation. These chillers are available for a cooling capacity between 7 and 800 kW, depending on the chiller model.

Refrigeration equipment for positive and negative temperature rooms.

For small and medium-sized cold rooms for fresh product preservation applications between -5 and 10 °C, and product freezing between -5 and -25 °C, compact units or wall, door or ceiling monoblocks with R290, a natural refrigerant, can be the ideal solution. These units are available with a refrigeration capacity between 0.6 and 2.5 kW.

If the installer decides to install an HFC unit, he can always do so with compact units or monoblocks that are available for a cooling capacity between 0.5 and 4 kW, or with split or semicompact systems that have a cooling capacity range between 0.6 and 14 kW.

For larger industrial cold rooms, it is possible to install compact R290 or HFC equipment, direct expansion systems or indirect systems, depending on the regulations in force in each country, as there are installation limitations depending on the refrigerant charge, or the kws of power.

Refrigeration equipment for tunnel freezers.

For freezing tunnels with temperatures down to -30°C, it is recommended to install a compact ammonia direct expansion unit with low NH3 refrigerant charge technology, no water consumption and Plug & Play installation.

Which refrigerant is suitable for which cold room?

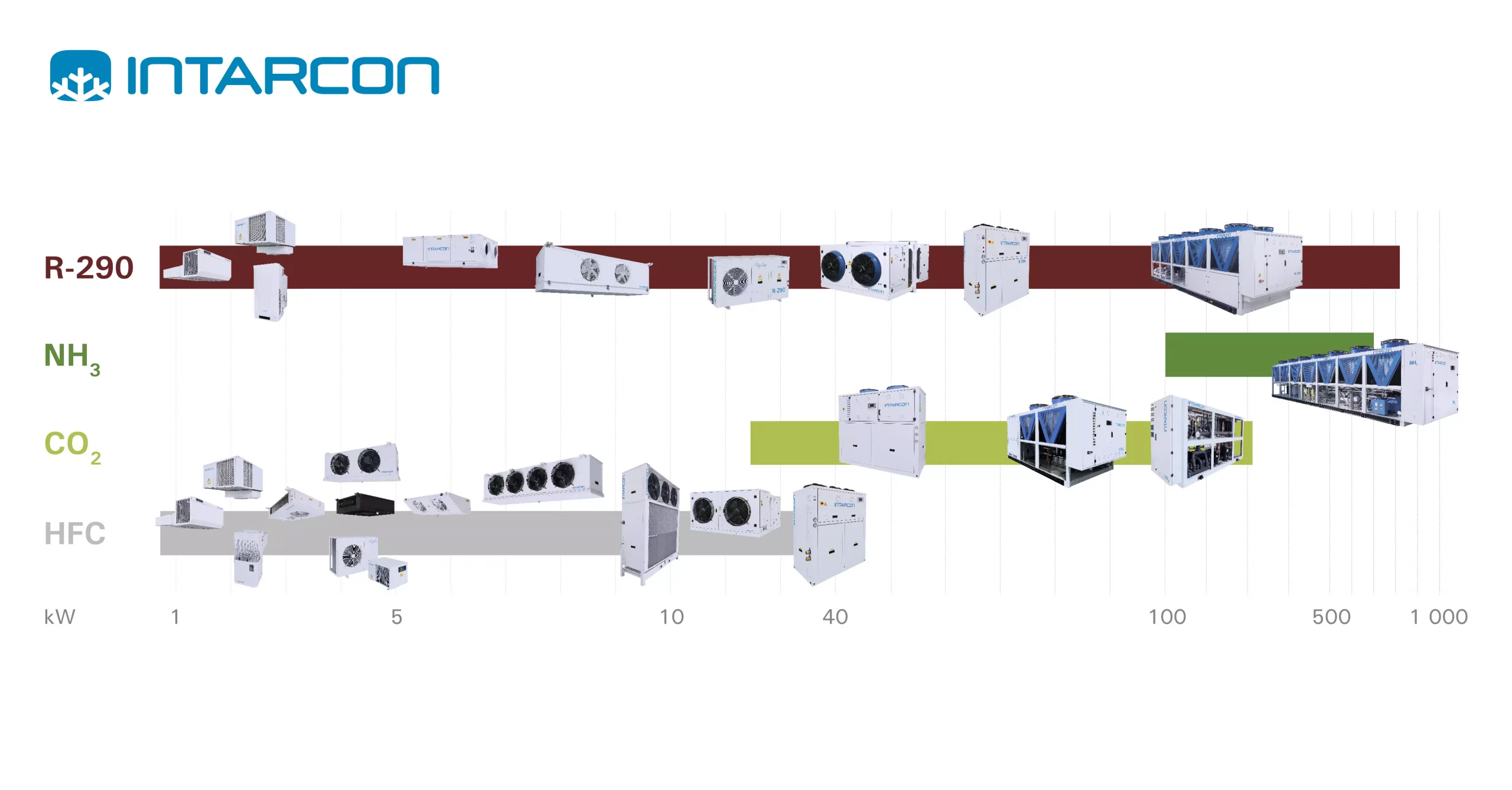

Depending on the type of refrigerant used for the refrigeration equipment, we could talk about equipment with technologies for natural refrigerants such as R290, CO2 or NH3, or technologies for HFC refrigerants.

How to choose the right refrigeration equipment for your cold store?

When selecting the refrigeration equipment, the heart of the cold room, we must take into account the regulations in force in the country where it is going to be installed, as it may have limitations depending on the refrigerant charge and the kws of power.

INTARCON has the Calcooling tool, a software package developed to calculate the refrigeration needs of a cold room and select the appropriate refrigeration unit. After entering certain parameters, such as the type of cold room (modular, refrigerated cabinet, display cabinet, site cabinet…), the type of insulation and the size, the software displays the calculated values.

In addition to indicating the type of cold room, the database of our software has the standard preservation parameters for all types of products (meat, vegetables, cereals, dairy products, fruit, pharmaceutical products, bread, wine, seafood…), and allows us to change the number of door openings, air changes, external humidity or even the load of products to be cooled in the cold room. With all this data, the tool gives us the cooling capacity needs of this room to conserve the product in an optimal way.

With these technical requirements, and taking into account the regulations for the installation of refrigeration equipment, we can select the ideal equipment for the cold room.