Efficient refrigeration installations in the service sector

INTARCON2024-09-25T14:17:45+02:00The constant search for maximum energy efficiency and better use of cooling energy consumption in the service sector leads to a centralisation of cooling systems, and in some cases to the integration of air conditioning in the same system, thus reducing the initial investment and annual electricity consumption, allowing a shorter return on investment.

The European Union is leading the transition to a more sustainable economy by implementing new legislation aimed at drastically reducing CO2 emissions. This drive has led to significant changes in the refrigeration sector, with the goal of increasing energy efficiency and reducing the carbon footprint. In the industrial sector, electricity consumption is one of the main costs, which has a direct impact on the competitiveness of products. Therefore, the focus on energy efficiency has intensified in order to cope with variations in energy costs and to promote greater sustainability.

In addition, the EU strategy includes improving energy efficiency as a central pillar for achieving climate neutrality, ensuring a just and prosperous transition. Energy efficiency measures not only avoid greenhouse gas emissions, but also reduce the demand for and price of valuable energy resources. According to the International Energy Agency’s report, doubling energy efficiency could reduce greenhouse gas emissions by almost a third by 2030.

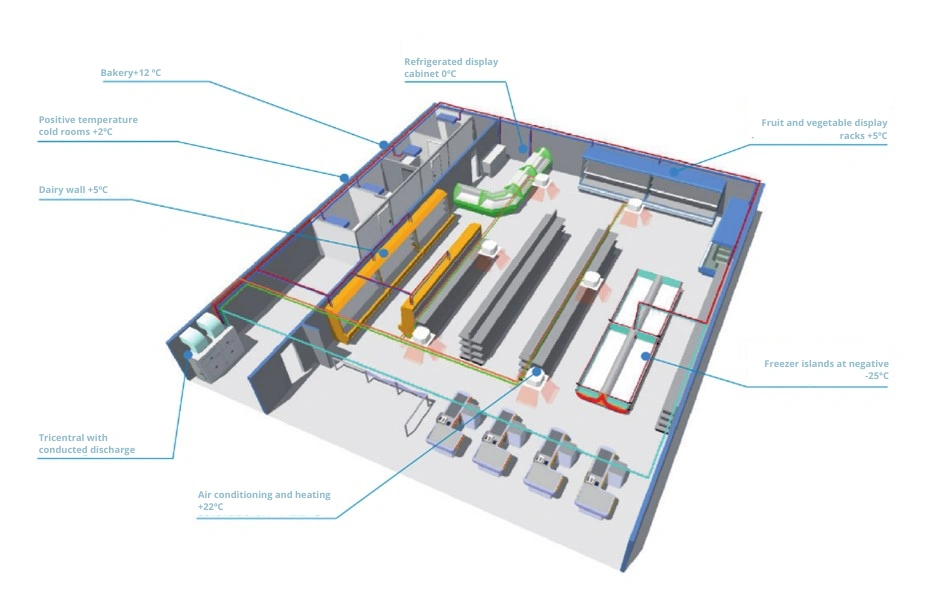

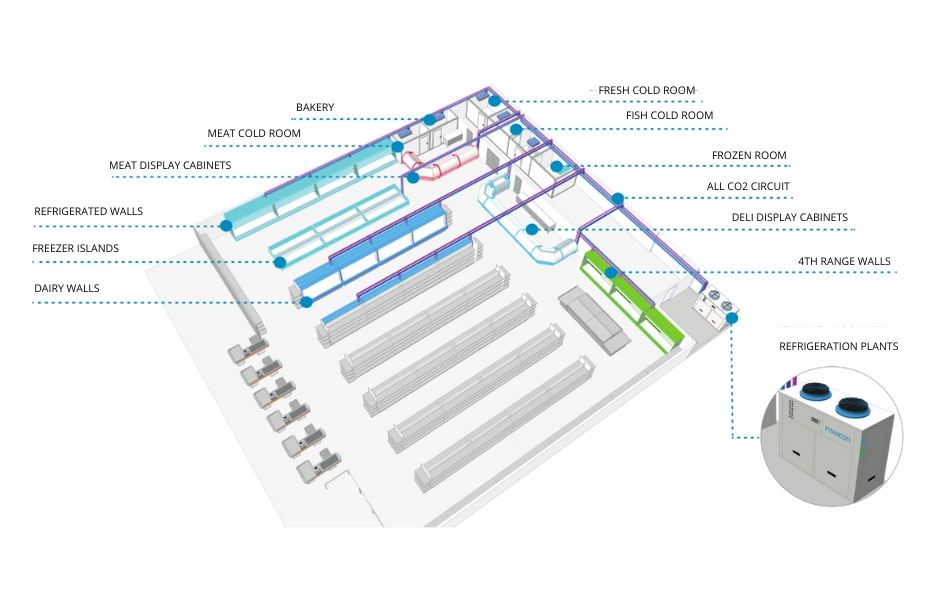

In the case of refrigeration in the service sector, where the retail, restaurant, hotel and catering, etc. sectors are found, chambers are required at different temperatures depending on the product they preserve or process, and air conditioning requirements, in addition to hot water needs (DHW) for surface sanitisation, support for the hot water circuit or heating.

One of the best and most widely used strategies in the refrigeration and air-conditioning sector is the use of centralised systems, as this reduces the resources needed to provide the same required cooling capacity:

- Cascade systems, which increase the SEPR of the installation.

- Variable speed drives, which reduce electrical consumption peaks and increase the useful life of the motors.

- Several suction lines to provide service at different temperatures simultaneously.

- VRC (Variable Refrigerant Capacity) system for refrigeration capacity regulation.

- Condensation heat recovery.

- Subcooling of the liquid line, which improves system performance.

- Use of natural or low GWP refrigerants.

- Indirect systems to reduce refrigerant charge.

INTARCON, given its experience in the centralisation of services, defends the use of natural refrigerants, such as propane (R-290), carbon dioxide (R-744) and ammonia (R-717), as a solution for the future in accordance with F-Gas regulations, as well as for its greater energy efficiency.

R-744 and R-717 are mainly used in direct expansion systems for negative temperature chambers due to their high cooling capacity thanks to their thermodynamic characteristics. And R-290 and R-717 are used in indirect expansion systems with the idea of providing safety in the installation by reducing the load and confining the gas in a specific area, increasing safety, minimising the possibility of leaks and reducing the environmental impact. Most direct expansion installations have an indirect expansion alternative.

Although in refrigeration in the service sector, indirect expansion installations tend to be used for larger installations or projects, while direct expansion tends to focus on smaller projects.

Advantages and disadvantages of centralisation

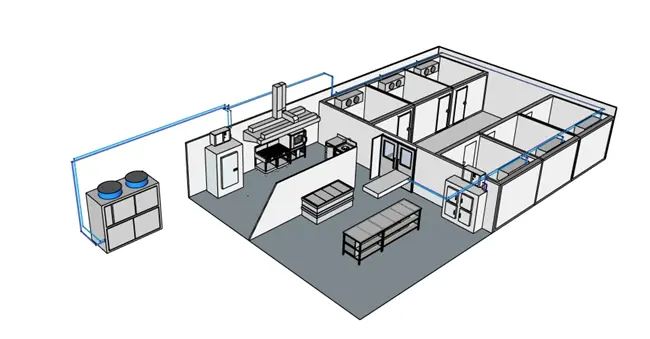

A suitable solution from a technical and economical point of view when it is necessary to provide cooling for numerous services is the centralised installation. This option is ideal when more than three or four evaporators need to be installed and a machine room or terrace is available close to the cooling supply points.

Advantages of centralised installation compared to stand-alone systems:

- Integral control of the system.

- Significant energy savings, facilitated by systems such as condensation and floating evaporation, variable speed drives, or hot gas defrosting, among others.

- Simplified maintenance due to the joint location of all cooling production components in a single zone or machine room.

- Cost reduction due to:

- Capacity for power staggering, which reduces the need for a compressor for each chamber or service.

- Use of common components such as condenser and liquid receiver.

- Lower installed power thanks to the application of the simultaneity factor.

Disadvantages of centralised installation compared to stand-alone systems:

- Best qualified refrigeration personnel.

- Specific regulations according to RSIF and F-Gas:

- Necessity of a technical project for electrical installations above 30 kW (RSIF).

- High costs and restrictions for HFC refrigerants (F-Gas).

- Alternative: Use of natural refrigerants such as CO2 in direct expansion, or converting the plant to an indirect expansion system, which significantly reduces the refrigerant charge in the system and allows maintaining an installation as Tier 1, simplifying the regulatory requirements for the installer.

| LEVEL 1 | LEVEL 2 | |

|---|---|---|

| System composition | They will not serve artificial atmosphere chambers and must use refrigerants from group L1, additionally fulfilling one of the following two conditions:

|

They must meet one of the following conditions:

|

| Requirements for the refrigeration company |

|

In addition to the 5 requirements required for a Level 1 refrigeration company, they must:

|

| Technical documentation prior to the execution of the installation |

|

|

Benefits of centralisation

Benefits of centralisationHow does a centralised system reduce the return on investment in the service sector?

- Integral management: it allows complete management of the installation, facilitating its operation and preventing possible failures.

- Energy optimisation: it favours efficient energy use and distribution, which translates into significant savings.

- Ease of maintenance: by bringing all the equipment together in one place, maintenance and repair tasks are simplified.

- Lower power demand: the centralised installation takes advantage of the simultaneity of the equipment, resulting in a reduction of the power required.

- Heat recovery: the thermal energy generated during cooling production can be used to cover the DHW demand and support the hot water loop free of charge.

- Efficient pumping systems with flow variation: allows modulation of the flow of the hydraulic circuit allowing it to be adjusted to the needs of the system, thus reducing electrical consumption and increasing the useful life of the component.

- Hybridisation with other technologies: allows the coupling of technologies such as thermal storage, renewable energy production plants through ‘Smart grid’ such as photovoltaic or solar thermal, etc.

Refrigeration solutions in the service sector

Example of installation renovation by replacement

In order to comply with the EU F-gas regulatory framework, the vast majority of centralised installations have been forced to replace their equipment and reduce the refrigerant charge or replace the HFC refrigerant with a low GWP refrigerant (<150), a natural refrigerant such as propane (R-290) or carbon dioxide (R-744), or switch to an indirect expansion system.

A clear example is the replacement of installations such as the tricentral 3pack by direct expansion systems with natural refrigerants or low GWP refrigerants such as R-744, or by indirect expansion systems using full-inverter chiller plants and indirect condensation equipment and air coolers, considerably reducing the refrigerant charge in the system, thus reducing the cost of the installation and its maintenance, and reducing the probability of leakage and thus its carbon footprint.

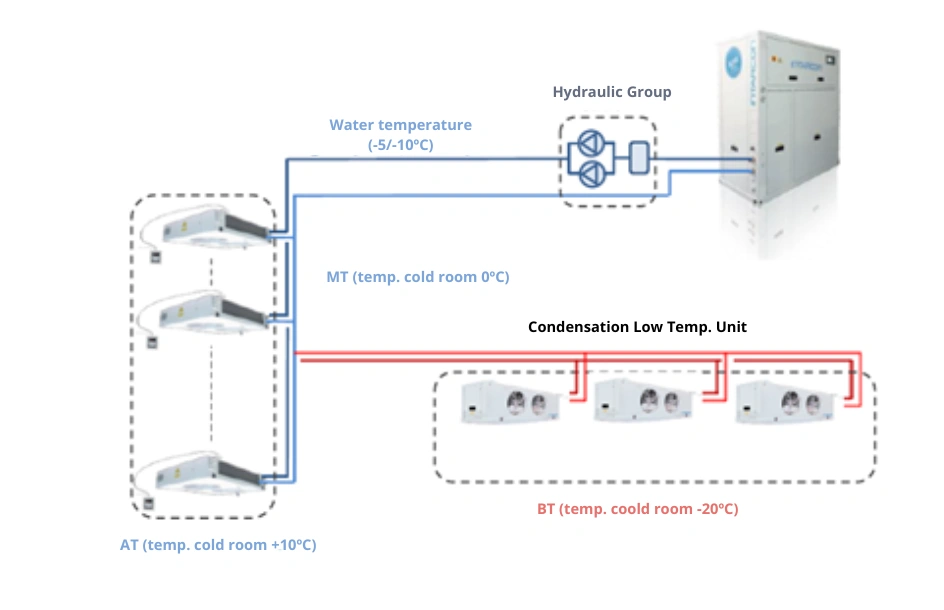

Indirect systems (full inverter air/water or water/water chiller plant ± drycooler, with air coolers and Waterloop system)

Features

- Low refrigerant charge.

- Confinement of the refrigerant in a small, localised area.

- Simple, safe and efficient installation.

- Coupling to indirect condensing equipment, air coolers, air conditioners, etc..

- Simultaneous production of cooling + heating, generation of a heating capacity 20-30% higher than the cooling capacity, which can be accumulated and used thanks to the recovery of condensation heat.

- Heat recovery makes it possible to eliminate energy consumption for DHW production, defrosting, air conditioning, etc., thus reducing the consumption of non-renewable primary energy.

- Environmentally friendly heat transfer fluid (water/glycol/brine), providing safety for the product and people when using water, glycol or brine, and eliminating the environmental contamination factor in the event of possible leaks.

- Variable speed drives in refrigeration compression systems and efficient hydraulic pumping reduce energy consumption by 20%:

- higher seasonal average efficiency,

- better control of power peaks,

- reduced oversizing,

- longer component life.

- Hybridisation with other technologies such as thermal storage systems, air conditioning, AHUs, renewable systems such as photovoltaic or solar thermal systems, etc.

- Independent refrigeration circuits, INTARCON chiller plants are designed with independent refrigeration circuits and condensers, so that during maintenance work the refrigeration capacity of essential services such as cold rooms can be maintained and to avoid interrupting the cold chain, which is essential for refrigeration in the service sector.

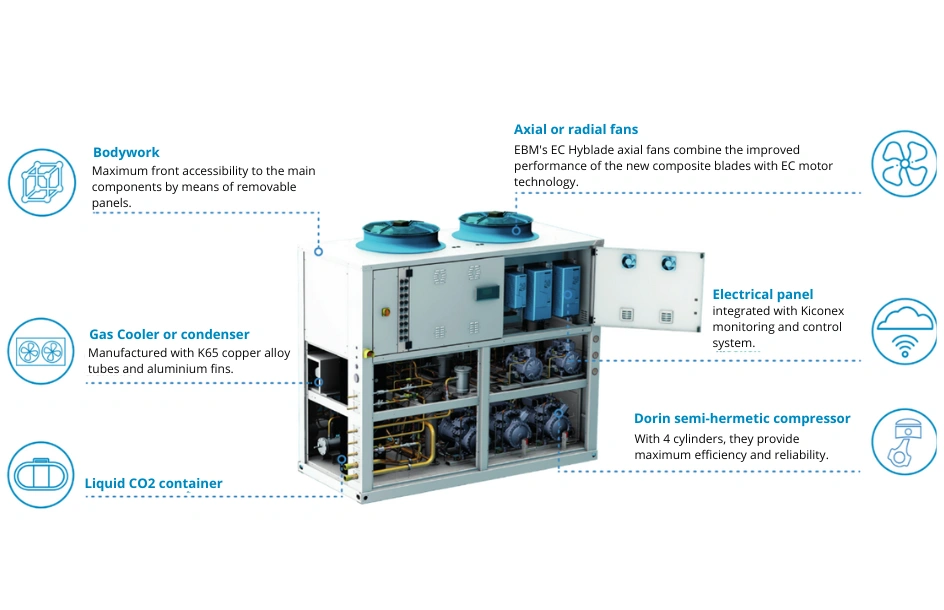

Direct system (ECO2SYSTEM with CO2 evaporators)

Features

- Compact transcritical cycle construction with built-in gas cooler, or in rack format with indirect condensing transcritical or subcritical cycle,

- Single or double suction for simultaneous production of positive and negative refrigeration,

Cascade cycle, offering excellent refrigeration performance in low temperature applications (cold rooms and freezing tunnels), - Parallel compression, in transcritical cycles improves energy efficiency at high ambient temperature,

- Economiser – subcooler, improves efficiency by cooling the liquid line,

- Hot gas defrost,

- Heat recovery, for DHW or heating.

- Emergency unit for CO2 maintenance.

Comparative table

Below is a table comparing the different systems discussed:| Recommended application (temperature) | COP | Initial investment | Maintenance | Refrigerant charge cost | |

|---|---|---|---|---|---|

| 3pack (tricentral) | Positive and negative | +++ | +++ | +++ | +++ |

| ECO2CUBE | Negative | +++ | +++ | ++ | + |

| Chiller plant + Waterloop | Positive and negative | ++ | ++ | + | + |

With these units you will save up to 20% on your electricity bill, one of the main costs of refrigeration in the service sector.

Call us and become another beneficiary of cutting-edge cooling technologies. Contact us and benefit from a differentiation in your sector thanks to our latest generation equipment.