Defrost on refrigeration evaporators

INTARCON2024-07-01T08:43:35+02:00Defrost on refrigeration evaporators is an essential procedure to preserve the efficiency and optimum performance of refrigeration systems. Inspection and maintenance guarantee an efficient heat exchange inside the evaporator and ensure its correct operation.

Why does frost form?

The formation of frost on refrigeration evaporators is mainly the result of condensation and freezing of moisture in the air. This process starts when the air, circulating through the evaporator coil, cools down to its dew point, condensing the moisture present if we go below that temperature, transforming it into frost.

What is defrost on refrigeration evaporators?

Defrost is a process by which ice or frost build-up on the evaporator surface of a refrigeration system is removed. This process is part of the maintenance and proper operation of the equipment.

Types of defrost on refrigeration evaporators

The most commonly used types of defrosting in refrigeration evaporators are:

- Air defrost.

- Water defrosting.

- By electrical resistances.

- By gas or hot liquid.

Psychrometric analysis: A look at the process

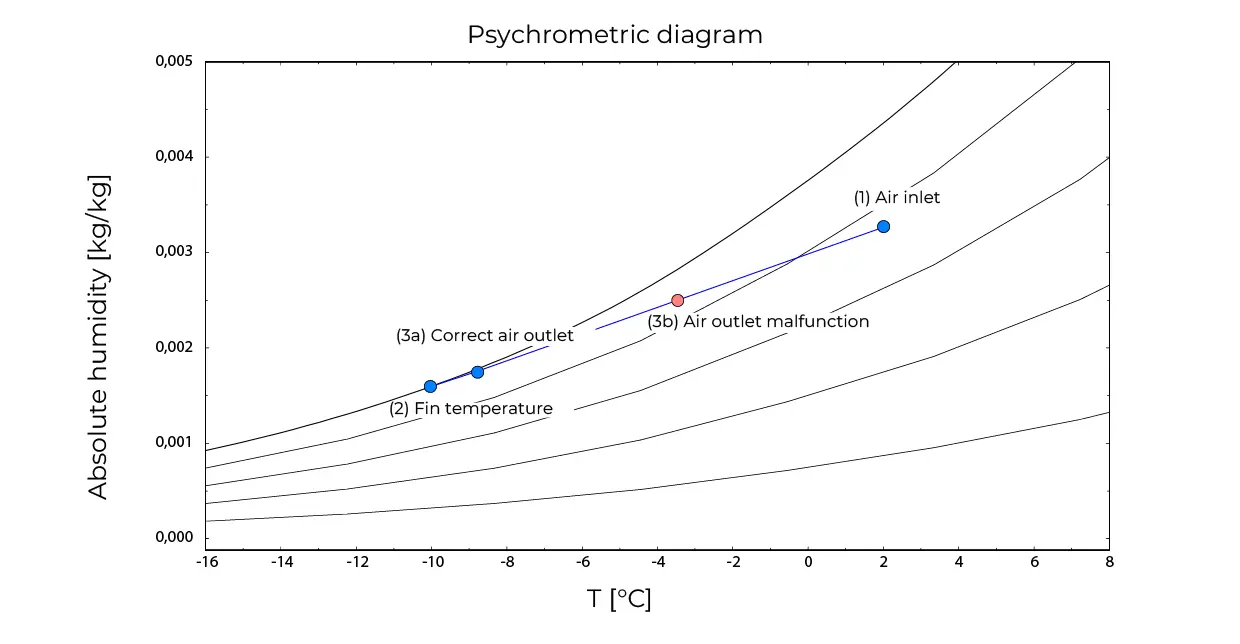

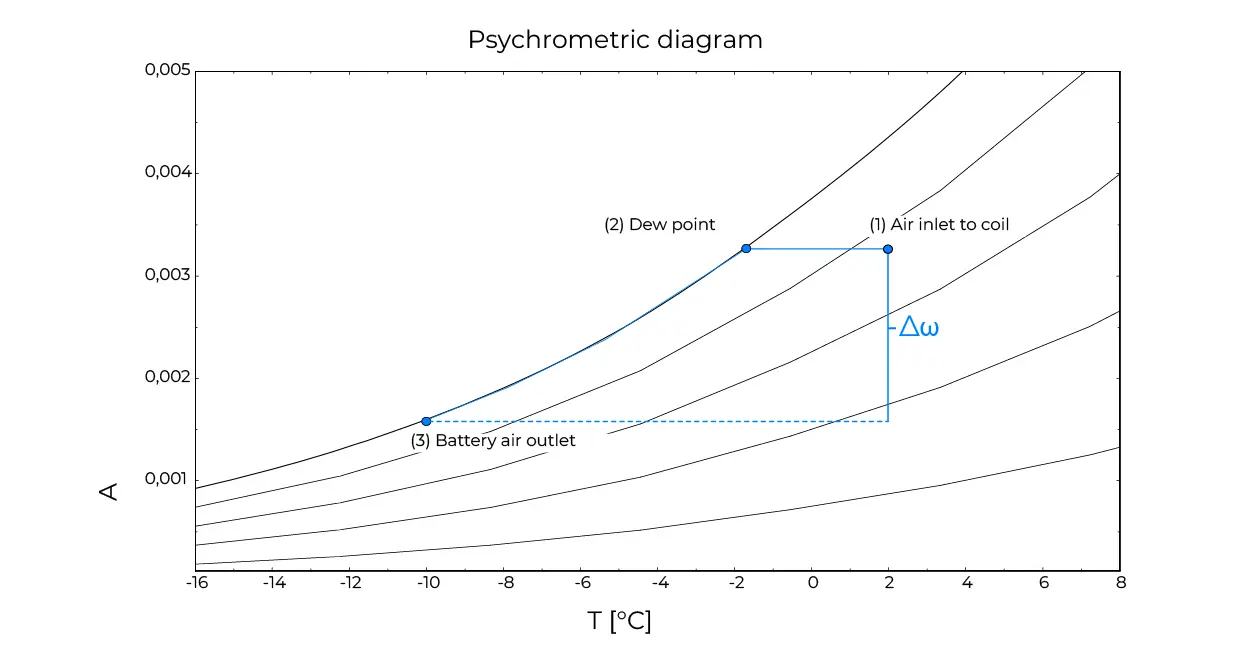

We use a psychrometric diagram to visualise this process. Here, sensible air cooling is represented as a horizontal movement to the left, from the air inlet to the dew point. Beyond this point, any further cooling leads to a reduction in the absolute humidity of the air, represented by a vertical downward movement in the diagram.

Practical example: Impact on cold rooms

Consider a cold room set at 0°C. With the air inlet temperature being slightly higher, e.g. 2°C, and the coil outlet temperature being -10°C, we observe that during sensible cooling, the absolute humidity remains constant until the dew point is reached. As cooling continues and crosses this point, the humidity condenses and subsequently freezes, forming frost.

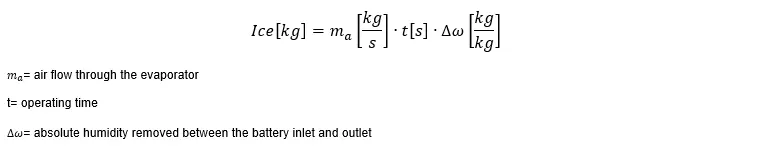

Calculation of frost formation

The amount of ice formed can be calculated using the following formula:

What is defrost on refrigeration evaporators used for?

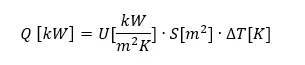

In refrigeration systems, ice or frost build-up on evaporators is a serious problem that significantly reduces the efficiency and operability of the system. When ice forms on evaporators, it acts as a thermal insulator, increasing the thermal resistance and decreasing the heat transfer capacity, which can be calculated by the following equation:

U= heat transfer coefficient in the evaporator

S= available heat exchange surface

ΔT= temperature difference between air inlet and evaporation (we consider equal fin)

As more ice forms, the heat transfer coefficient decreases, forcing the system to operate at lower temperatures and pressures to compensate. This not only increases energy consumption, but can also lead to unplanned system downtime, operational failures and accelerated component wear.

Importance of defrosts

Defrosting of refrigeration evaporators is crucial to maintain the operational efficiency of refrigeration systems. By regularly removing accumulated frost, it is achieved:

- Restore heat transfer capacity. Defrost on refrigeration evaporators allows the evaporator to operate at full capacity, allowing the system to operate under optimum design conditions.

- Reduce the need to operate in extreme conditions. By keeping evaporator surfaces free of ice, it avoids the need for the compressor to run off-design to compensate for transfer loss, reducing energy consumption.

- Preventing unwanted downtime. Effective frost removal prevents unwanted downtime due to low pressure or activation of safety measures related to excessive ice build-up.

How to solve the frost build-up on the evaporator coil?

Frost formation on evaporators in refrigeration systems can lead to a number of operational problems, significantly reducing system efficiency. Identifying and addressing the factors that contribute to this phenomenon is crucial to maintaining optimal performance. Below, we explore the main factors that encourage frost formation and strategies to mitigate them:

Moisture ingress in cold rooms

Cold rooms are not completely airtight; ingress of warm, moist air from the outside can be significant, especially through doors during opening or poor seals.

| Origin | Problem | Solution |

| Inadequate sealing and airtightness | Air leakage | Correct sealing and airtightness, inspection and identification |

| Doors, Curtains and Pre-Chamber | Frequent opening | Automatic doors, air curtains and strips, pre-cameras |

| Product packaging | Moisture release | Packaging techniques, pre-cooling of products… |

| Outdoor climate | Hot and humid climates | Physical barriers, entry control. |

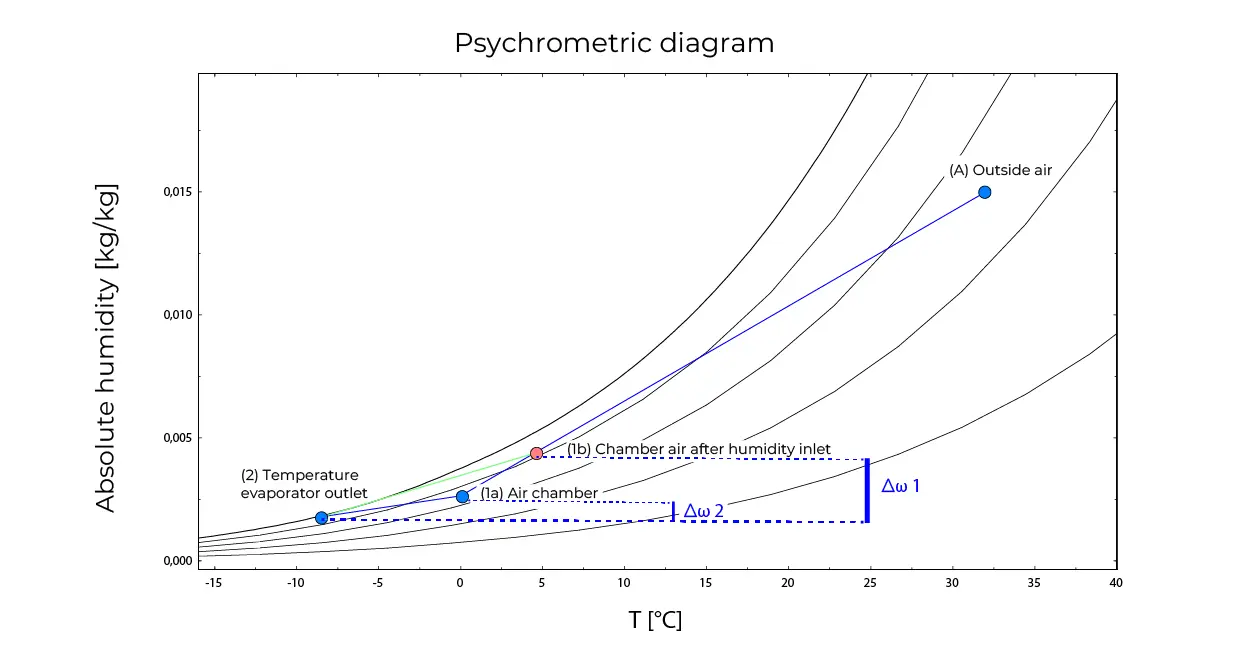

Imagine that the temperature of the air inside the cold room increases, moving from an initial state (point 1a) to a state with higher temperature and humidity (point 1b). This change is clearly illustrated in figure 3. At this new point, the absolute humidity is higher, which implies that more water vapour is available in the air.

With increasing humidity, as the air passes through the evaporator, the amount of moisture that reaches the dew point and subsequently condenses also increases (from Δw1 to Δw2).

Influence of the temperature range and impact of thermal bridging

The temperature range within a chamber determines whether the air will reach the dew point on the evaporator surfaces. In systems configured to stay above the dew point, the vapour does not condense, which prevents frost formation. However, with medium and low temperature requirements, reaching and exceeding the dew point is more common, increasing the risk of frost formation.

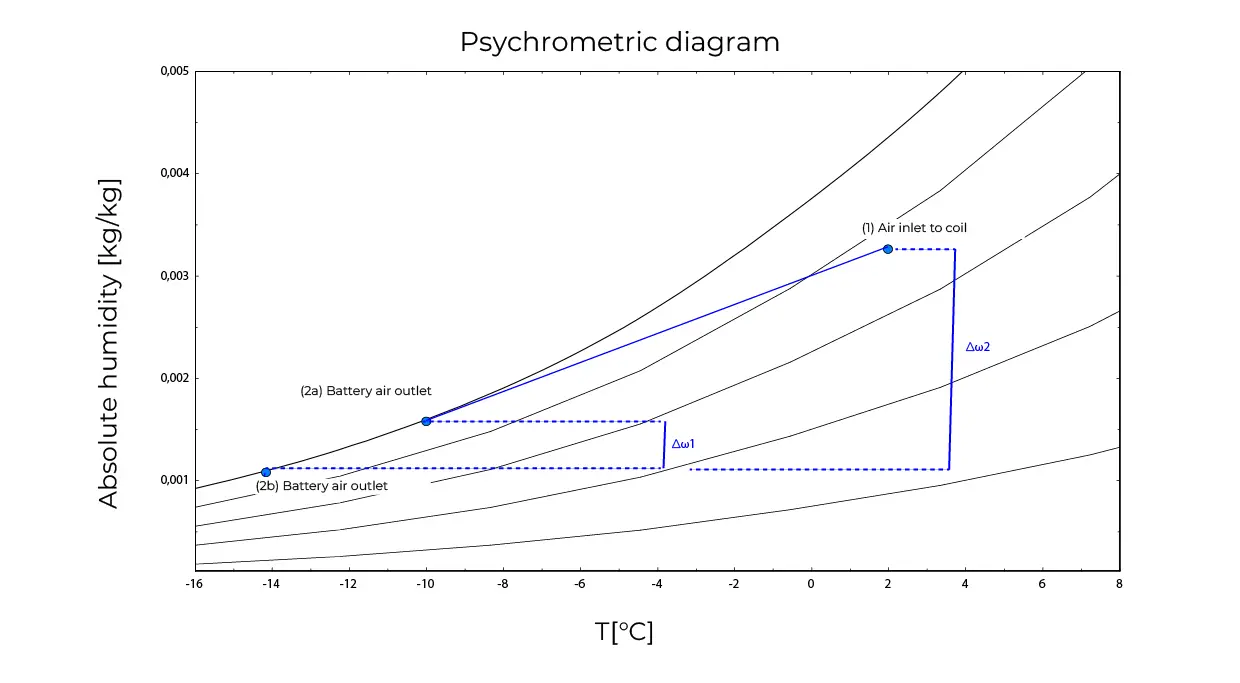

In addition, the thermal gap, defined as the difference between the air inlet temperature and evaporator temperature, directly influences the intensity of dehumidification. A higher thermal gap can lead to more moisture condensing and eventually freezing in the evaporator, as illustrated in the figure. As the thermal jump increases, the amount of absolute humidity that is removed also increases, moving from an initial state point 2a to a more critical state point 2b. This results in a change of the absolute humidity of the air from Δw1 to Δw2 leading to increased dehumidification.

Type of refrigerant and phase change slip

Some refrigerants experience what is known as “slip” during phase change, which means that the evaporating temperature is not constant throughout the evaporator. This can create colder spots where condensation and freezing of moisture is more likely.

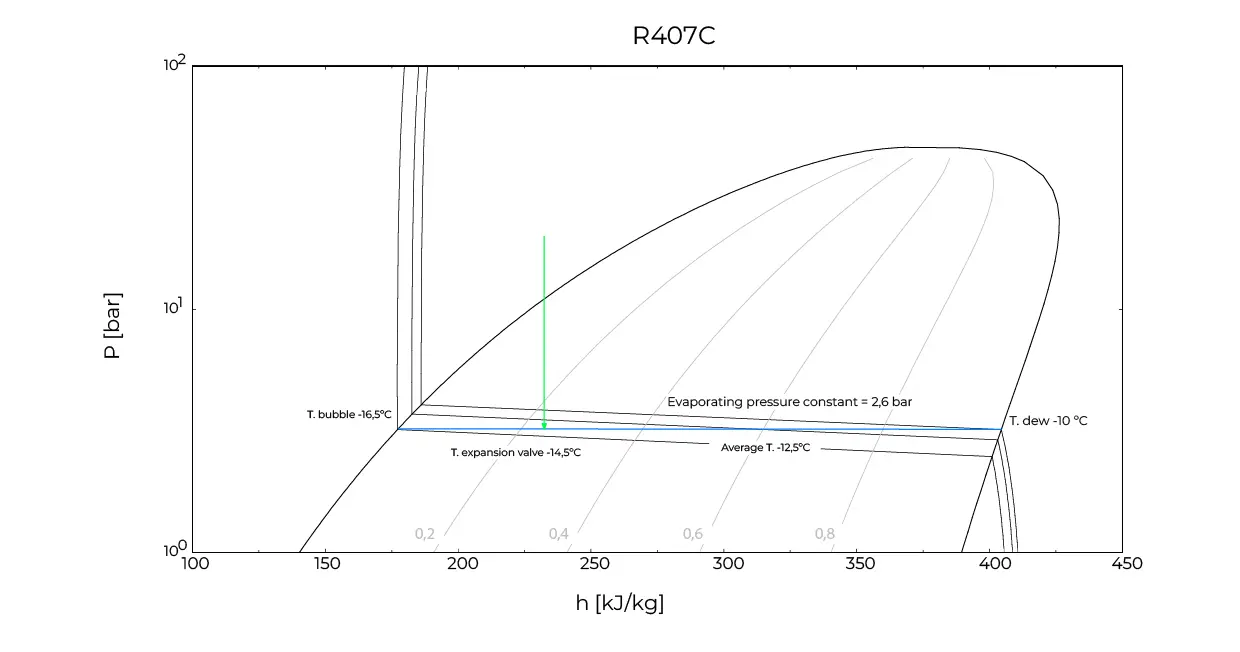

An analysis of the Mollier diagram as in figure 3 for R-407C refrigerant can help to visualise how the thermodynamic properties of the refrigerant affect evaporator operation and frost formation in a medium temperature situation, where the (refrigerant) dew temperature is -10°C, the average evaporating temperature is -12.5°C, the refrigerant expansion temperature is -14.5°C and the bubble temperature will be -16.5°C at a relative pressure of 2.6 bar.

Factors contributing to frost formation on evaporators

Frost formation on evaporators can also be caused by specific operational and maintenance problems. Each of these problems contributes differently to the phenomenon of frost formation and requires specific attention for its solution:

| Origin | Problem | Solution |

| Evaporator refrigerant leakage | Loss of pressure in refrigerant circuit and temperature loss | Regular inspections |

| Dirty and clogged evaporator | Imposibilidad de intercambio térmico | Schedule regular maintenance and cleaning |

| Lack of air flow through fans | Reduced heat exchange | Check fan operation |

| Plugged TEV or filter | Loss of pressure in refrigerant circuit and temperature loss | Inspect and adjust TEV. Replace filter. |

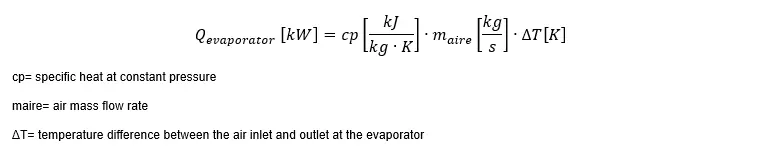

Evaporator cooling capacity

Dirt acts both as an insulator, reducing the transfer coefficient, and as an airflow obstruction, reducing the air mass flow rate. This relationship can be clearly seen in the equation of the cooling capacity offered by the evaporator.

This will require a lower outlet air temperature (higher gradient) and consequently, as we have seen in the case of the increase of the thermal jump, we increase the absolute humidity removed from the air in the chamber.

Cooling capacity of the circuit

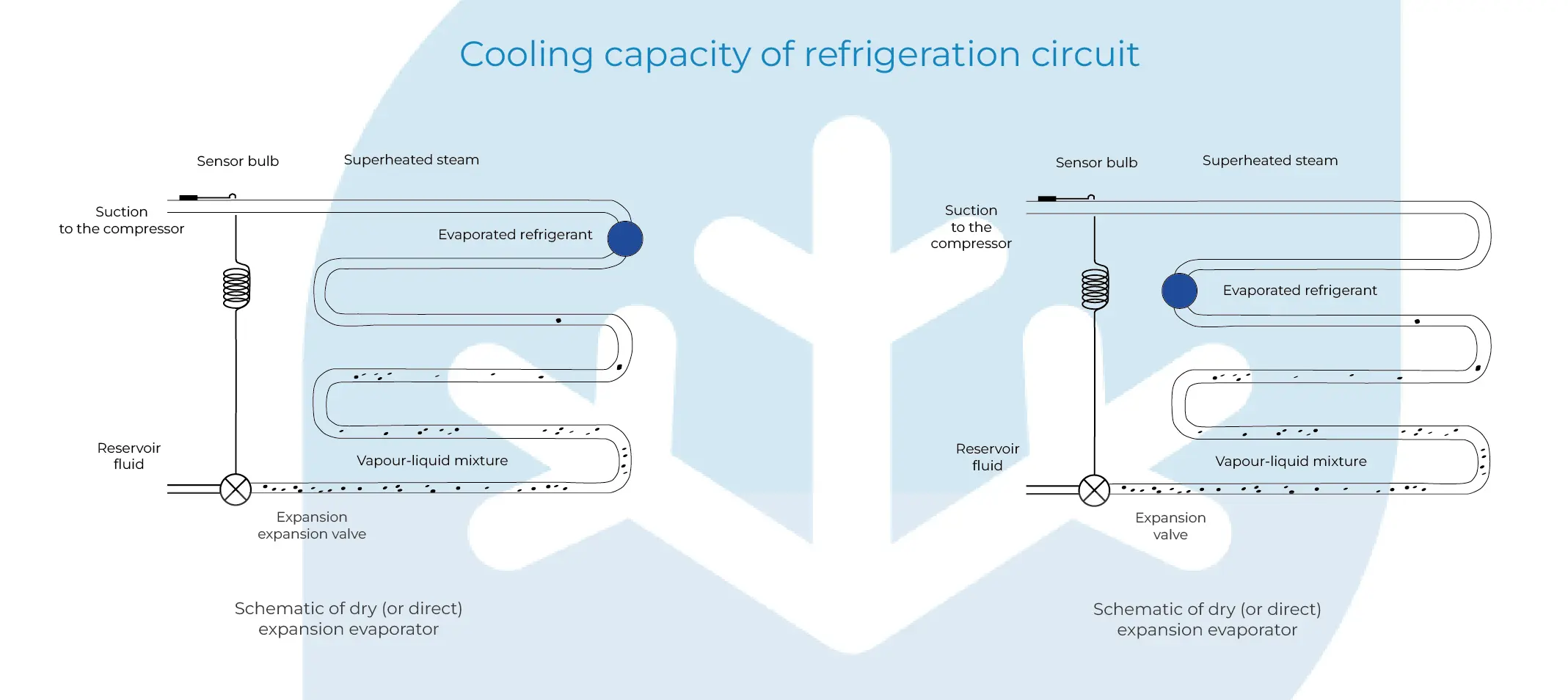

In the equation, if the mass flow rate circulating through the system is reduced, the cooling capacity of the equipment decreases. As a consequence, the cooling capacity of the evaporator will also decrease.

m_ref = refrigerant flow rate

Δh= enthalpy jump between refrigerant expansion to compressor suction

In a dry expansion evaporator, the refrigerant evaporates later, which increases the proportion of gas instead of liquid. This decreases the heat transfer coefficient and brings the outlet air temperature closer to the inlet air temperature, thus reducing the temperature difference in the air flow.

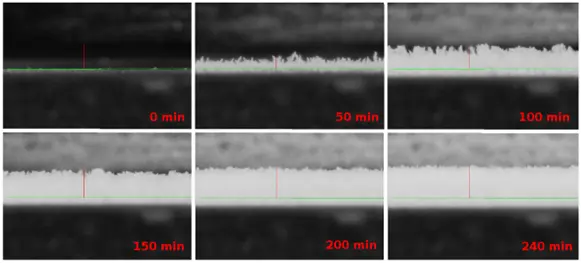

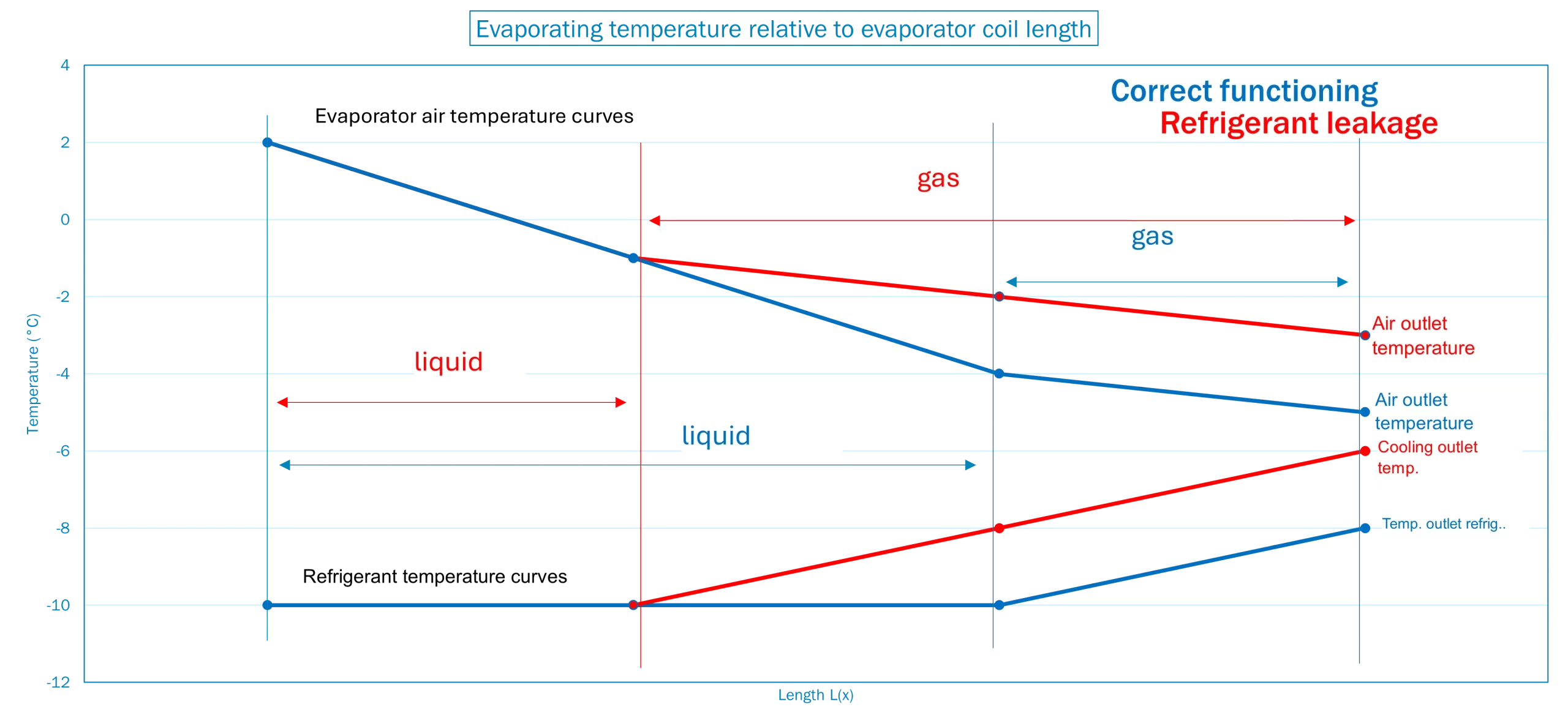

The figure shows the air and refrigerant temperature curves along the coil, in blue for normal operation and in red for a refrigerant leak. Early evaporation prolongs the time the refrigerant remains as a gas, decreasing the heat transfer coefficient. This results in less heat transfer and a higher air outlet temperature. In addition, the evaporated refrigerant becomes a superheated gas, which reduces the slope of the air temperature line.

The psychrometric diagram shows two cases: a normal case with 90% efficiency and a case with flow restriction.

- First case, the air outlet temperature is close to the evaporator fin temperature.

- Second case, with flow restriction, it moves away, closer to the inlet temperature.