Hot

R290 intarCUBE

R290 chillers

Chillers in compact construction with glycol, water or brine and a low charge of R290.

- Description

- Technical features

- Options

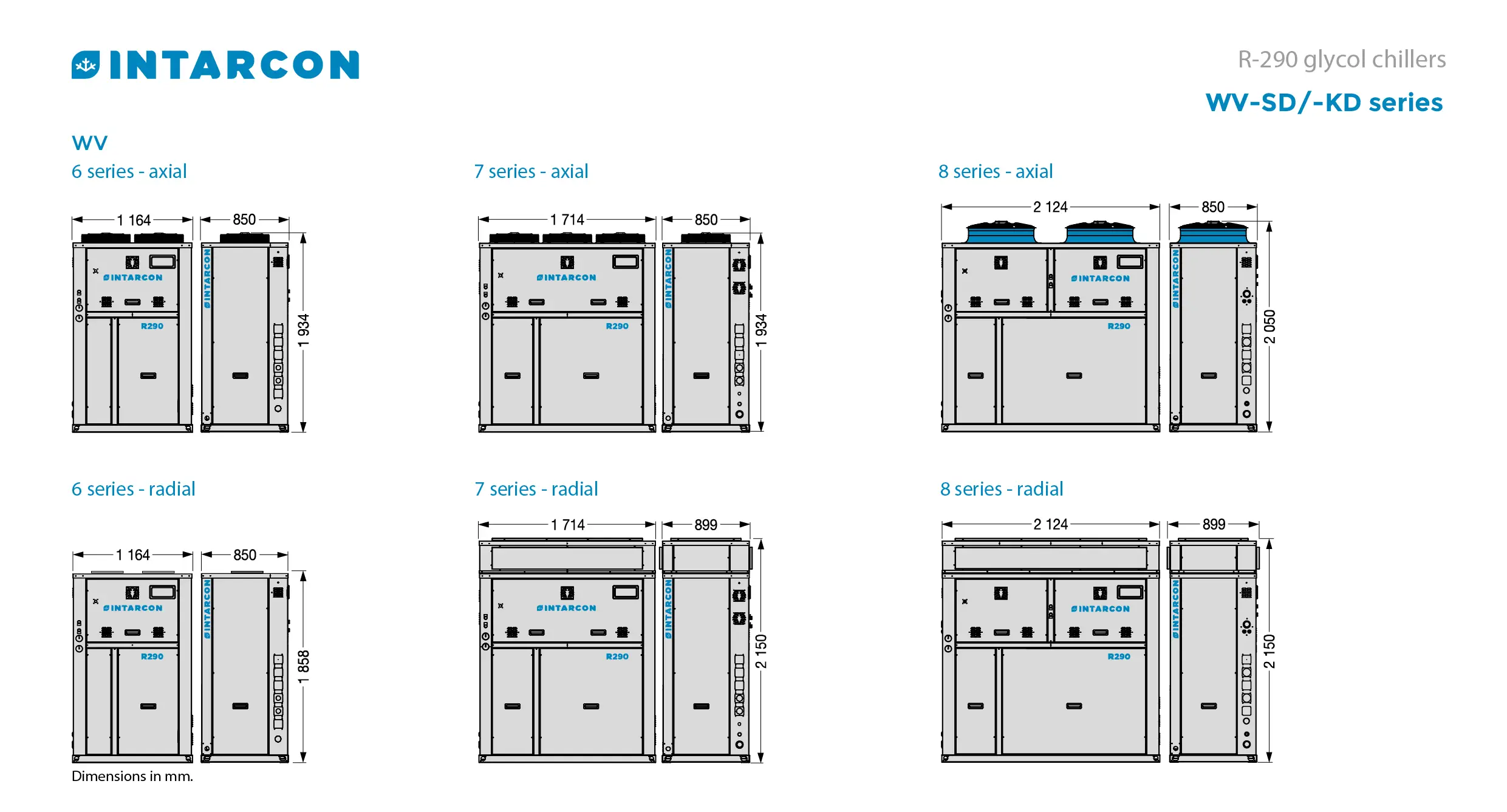

- Dimensions

- Documentation

Description

Water or glycol chiller for commercial and industrial refrigeration applications with reduced R-290 load, in vertical footprint construction with optional built-in hydraulic unit. These equipments are characterised by:

- Natural refrigerant R-290.

- High energy efficiency.

- Easy installation.

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- R-290 refrigerant.

- Self-supporting body made of galvanised steel sheet with polyester paint for outdoor use, with thermo-acoustic insulation of elastomeric foam. Side panels that can be opened around the entire perimeter.

- Separate compressor compartment with leak detector and ATEX extraction fan.

- Tandem or trio of scroll compressors for R-290 with acoustic insulation; or tandem of semihermetic compressors for R-290 with capacity control and unloaded start, with crankcase unloaded, with crankcase heater.

- Refrigerating circuit made of annealed copper tube with soldered joints, filter drier, pressure filter drier, ATEX high and low pressure switches, pressure transducers and temperature probes.

- Condenser coil of copper microtube and aluminium fins.

- Electronic fans.

- Electrical control and power panel with magneno-thermal and differential protection independent of compressors, fans and pumps.

- Stainless steel plate evaporator with electronic expansion valve.

- Economiser by means of internal heat exchanger.

- Programmable Emerson electronic control unit with refrigeration control, condensing fan control with floating set point, pump control, etc.

- Threaded hydraulic connections.

- Glycerine pressure gauges.

- Machine room version with EC radial fans for exhaust air ducting.

- Anti-corrosion treatment based on polyurethane coating for the condensing coil.

- Electronic control and spare driver.

- Silentblocks for equipment installation.

- Heat recovery (20 or 80 % heat from the condenser) for hot water generation.

- Built-in hydraulic group made of copper pipe with threaded connections, with glycol circulating pump with stainless steel body and impeller, and optional backing pump, expansion vessel, safety valve, mesh filter, thermometers and pressure gauges, air vent and drainage inlet (except 8 series and units with heat recovery).

- External hydraulic group.