intarWatt

Glycol chillers

Chillers in compact construction and outdoor installation for glycol.

- Description

- Technical features

- Options

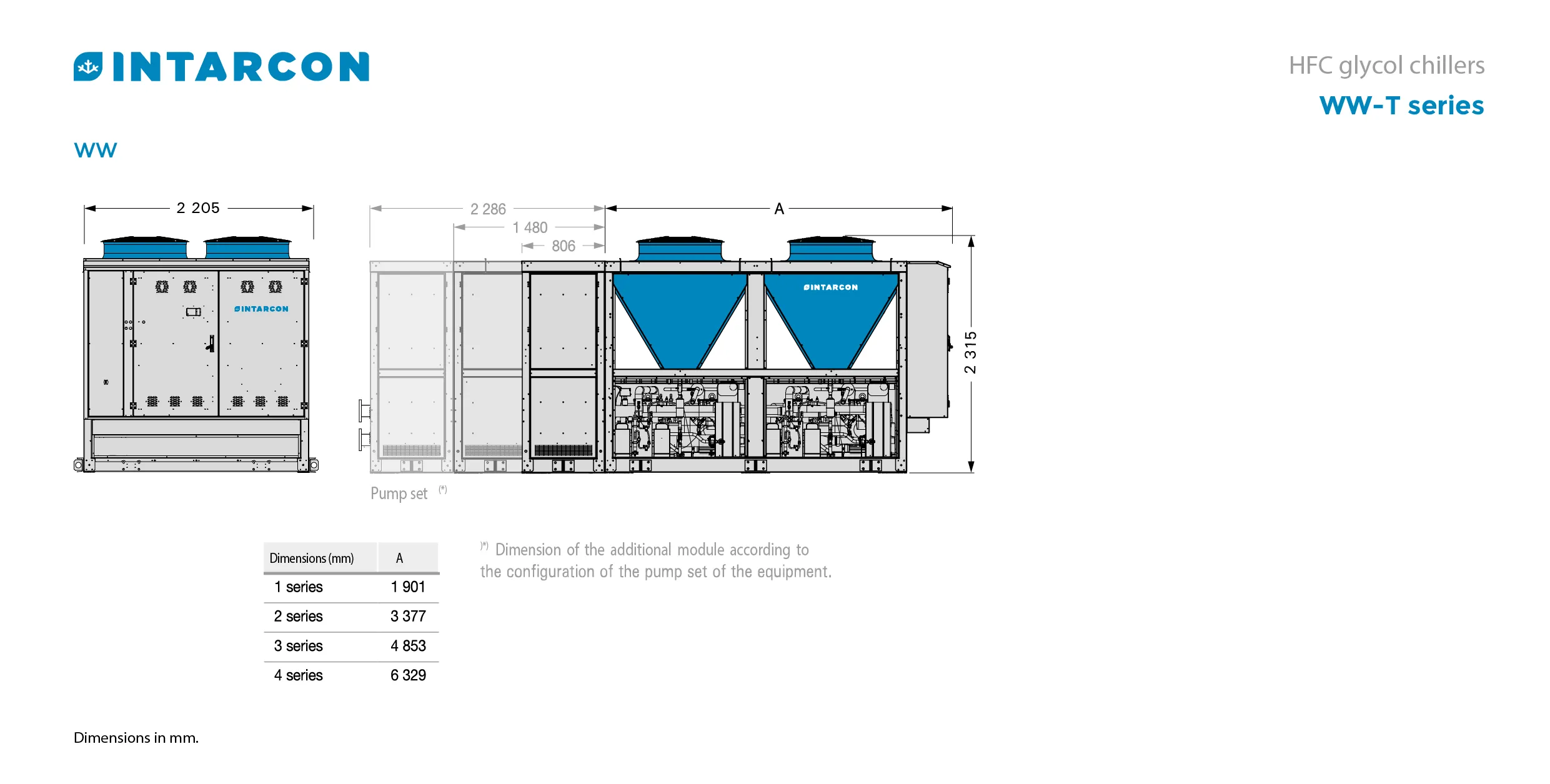

- Dimensions

- Documentation

Description

Air-cooled water or glycol chillers for industrial applications. They are characterised by a very compact construction, designed for outdoor use, which integrates the semihermetic compressors, air condensers with V-coil arrangement, plate heat exchanger and the control panel.

- Built-in hydraulic circuit (optional).

- No need for machine room.

- Minimum refrigerant charge.

- Optimised compact system with minimum maintenance.

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Semihermetic Copeland Stream compressors, damper-mounted and acoustically insulated, with power partialisation, rotalock service valves, crankcase heater and electronic protection and diagnostics module.

- High-efficiency condensing coils in V-arrangement, made of copper tubes and aluminium fins, with double-speed axial motor fans Ø 800 mm.

- Cooling circuits made of annealed copper or steel tube equipped with high and low pressure switches, service valves, filter and sight glass.

- Copper brazed stainless steel plate heat exchanger with anti-freeze heating element.

- Hydraulic circuit made of copper pipe with threaded connections, fill/drain valve, flow switch, thermometers and inlet/outlet pressure gauges. Threaded connections up to 2 1/2″ and following with flange connection.

- Electric control panel with thermal, magneto-thermal and differential protection for each compressor and fan.

- Electronic control with control of power stages, high and low pressure transducers, anti-freeze control and digital control interface.

- Integrated hydraulic unit (see page 114).

- Secondary pump and/or frequency converter.

- Variable speed EC electronic fans.

- Anti-corrosion coating on condensing coil.

- Cooling circuit closing panels.

- Interior fairing of frigorific compartment.

- Motor guards with manual reset on compressors.

- Heat recovery (20 or 80 % condenser heat) for hot water generation.