Types of defrost in refrigeration

INTARCON2025-08-11T13:55:21+02:00The defrost process in refrigeration systems is crucial for the correct operation of the equipment and allows the removal of the frost generated after dehumidification and subsequent freezing of the humidity in the air.

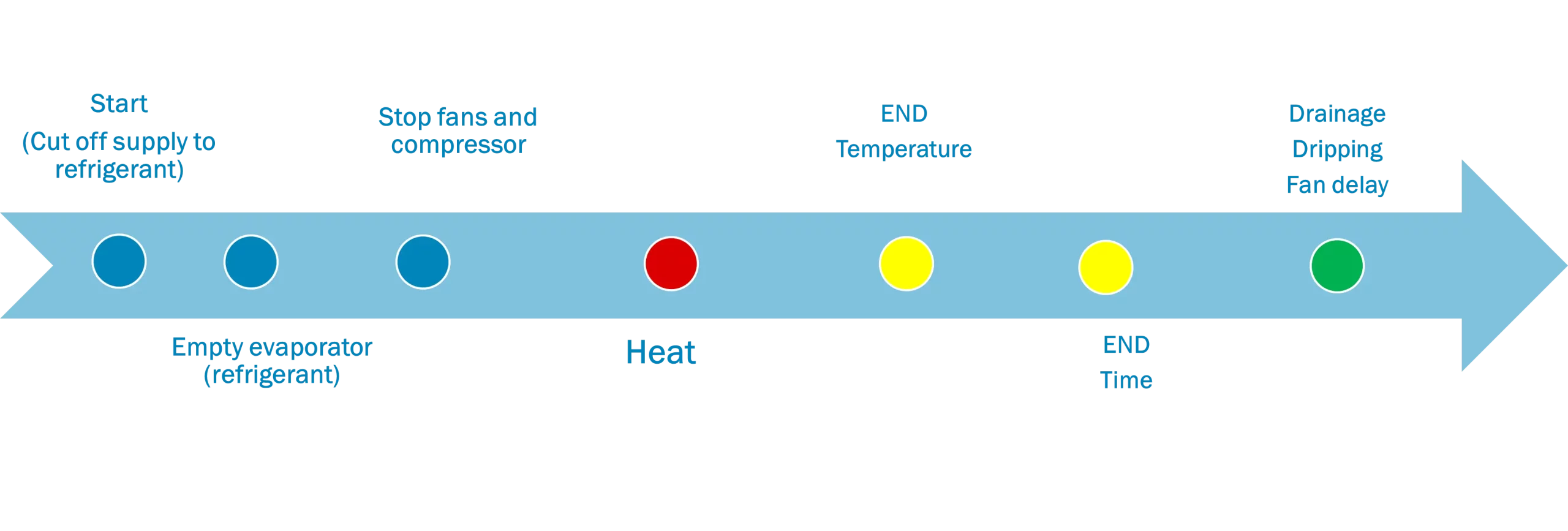

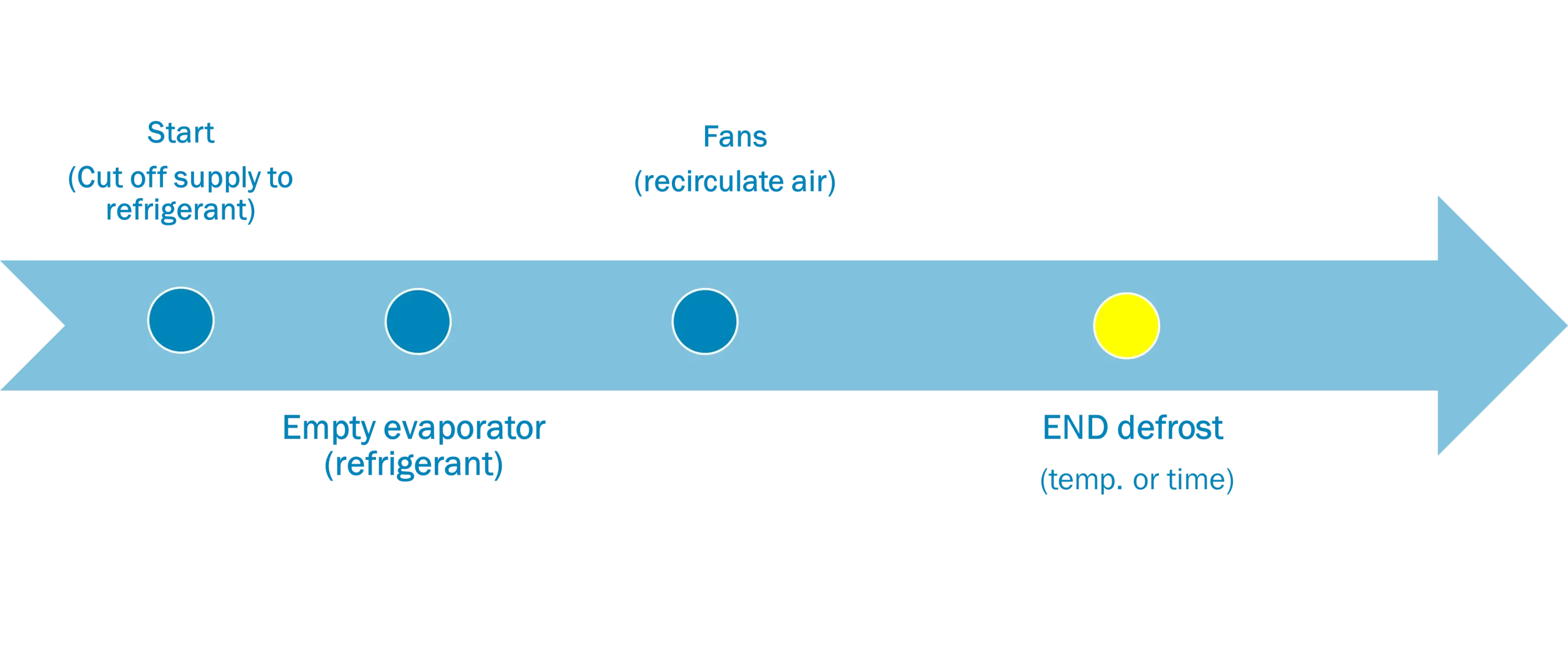

First, we plan a defrost schedule, where we agree on the frequency of defrosting. Initially, by closing the refrigerant solenoid valve to prevent the refrigerant from entering the evaporator, the compressor sucks the remaining refrigerant until it stops due to low pressure. This process allows the system to completely and safely empty the evaporator. During defrosting, in general, both compressors and fans are switched off to minimise the flow of hot air into the refrigerated chamber.

Defrosts involve providing sufficient heat to melt the accumulated ice, using different heat sources depending on the method employed, such as air, water, electric heaters or hot gas from the compressor. The defrost ends when a probe detects that the temperature is above 0°C or when a predefined time has elapsed, ensuring that the process is effective and consistent.

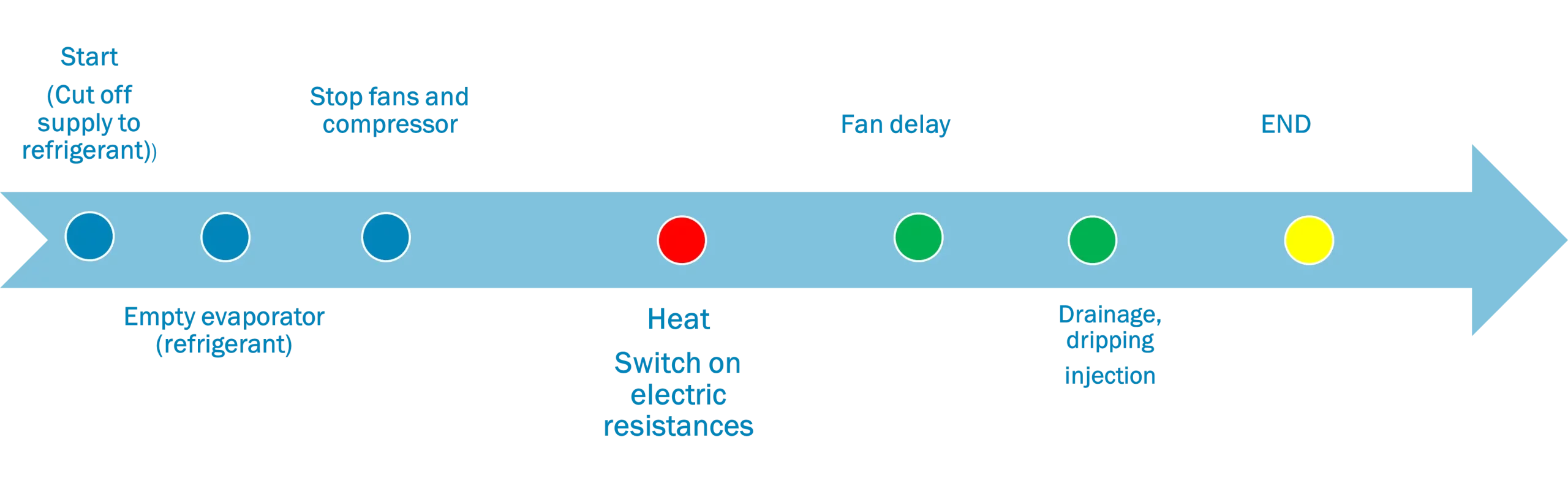

In addition to these steps, it is essential to consider delay times such as drip, dry-out, drain or injection time to allow water to drain and the evaporator to cool, reducing thermal shock and stabilising conditions inside the chamber. These practices not only improve the energy efficiency and operation of refrigeration systems, but also extend the life of the equipment, maintaining optimal and safe product preservation.

Types of defrost

In refrigeration systems, the effectiveness of defrost will depend on the ability of the method used to generate sufficient heat to melt the accumulated ice, minimising energy consumption and time required. The most common methods include air defrost, electric resistance defrost, hot gas defrost, hot glycol defrost and reverse cycle defrost. Each has its particularities and should be selected based on efficiency as well as its impact on the stored products.

Air defrosting

In refrigeration, air defrost is an effective method of combating ice build-up in evaporators. This process uses the air in the chamber itself to defrost the frost efficiently.

Its suitability is intensified in chambers above 4ºC, as at lower temperatures its effectiveness is reduced.

The system starts with the closing of the liquid solenoid valve, which stops the refrigerant flow to the evaporator and to be emptied by the compressor until it stops. In this case the fans recirculate the air in the chamber passing it through the coil, facilitating the defrosting of the accumulated ice. The defrost process ends automatically, either by detection of the defrost set point temperature by means of a probe or by compliance with the time set in the system, ensuring that the evaporator returns to normal operation without thermal shocks with a smooth transition to the resumption of refrigeration activity.

Air defrost is useful in environments that require meticulous humidity control, such as fruit and vegetable chambers or warehouses. It is also common in workrooms. Specialised INTARCON equipment, such as those in bottled wine cellars or barrels, and compact high-temperature industrial equipment, such as the R-290 superblock, use this method. In this way, they optimise the preservation environment and maintain the energy and operational efficiency of the system.

Electric resistance defrosting

In refrigeration, electric resistance defrosting is used as an effective and controlled method of eliminating frost build-up on evaporators. This system consists of integrating electric heating elements directly inside the evaporator, with the objective of heating the affected surface and melting the frost.

Resistor defrosting is widely used in commercial and industrial applications where precise control of the defrosting process is required.

The process is close to standard, starting with shutting off the liquid solenoid valve to stop the refrigerant flow, followed by draining the compressor. The fans and compressors are then shut down simultaneously to prepare the system. Next, the electric heaters are activated, which are selected to provide the amount of heat required to melt the frost in the desired time. The delay times are set appropriately to ensure that the defrost process is completed efficiently.

Hot gas defrost

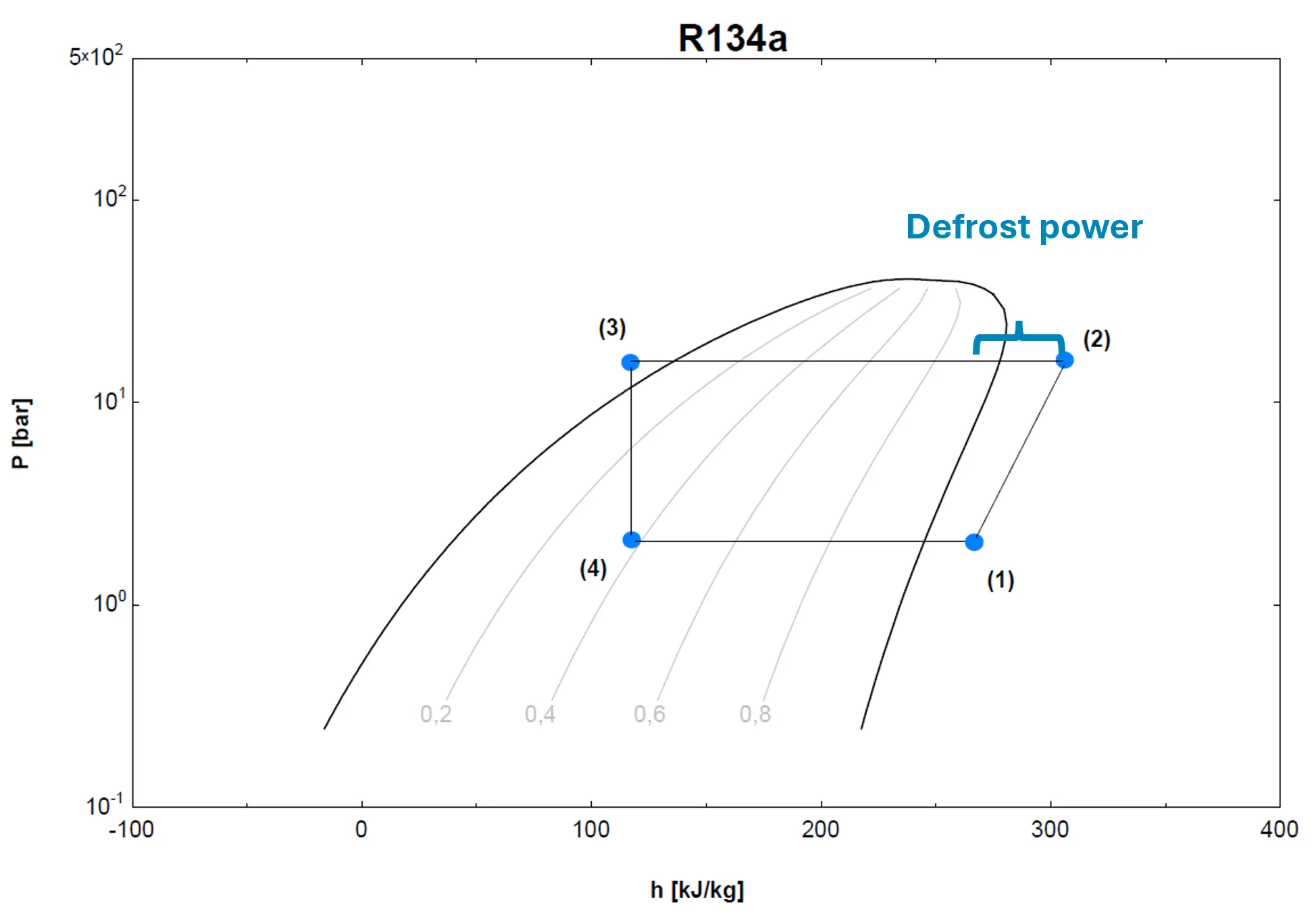

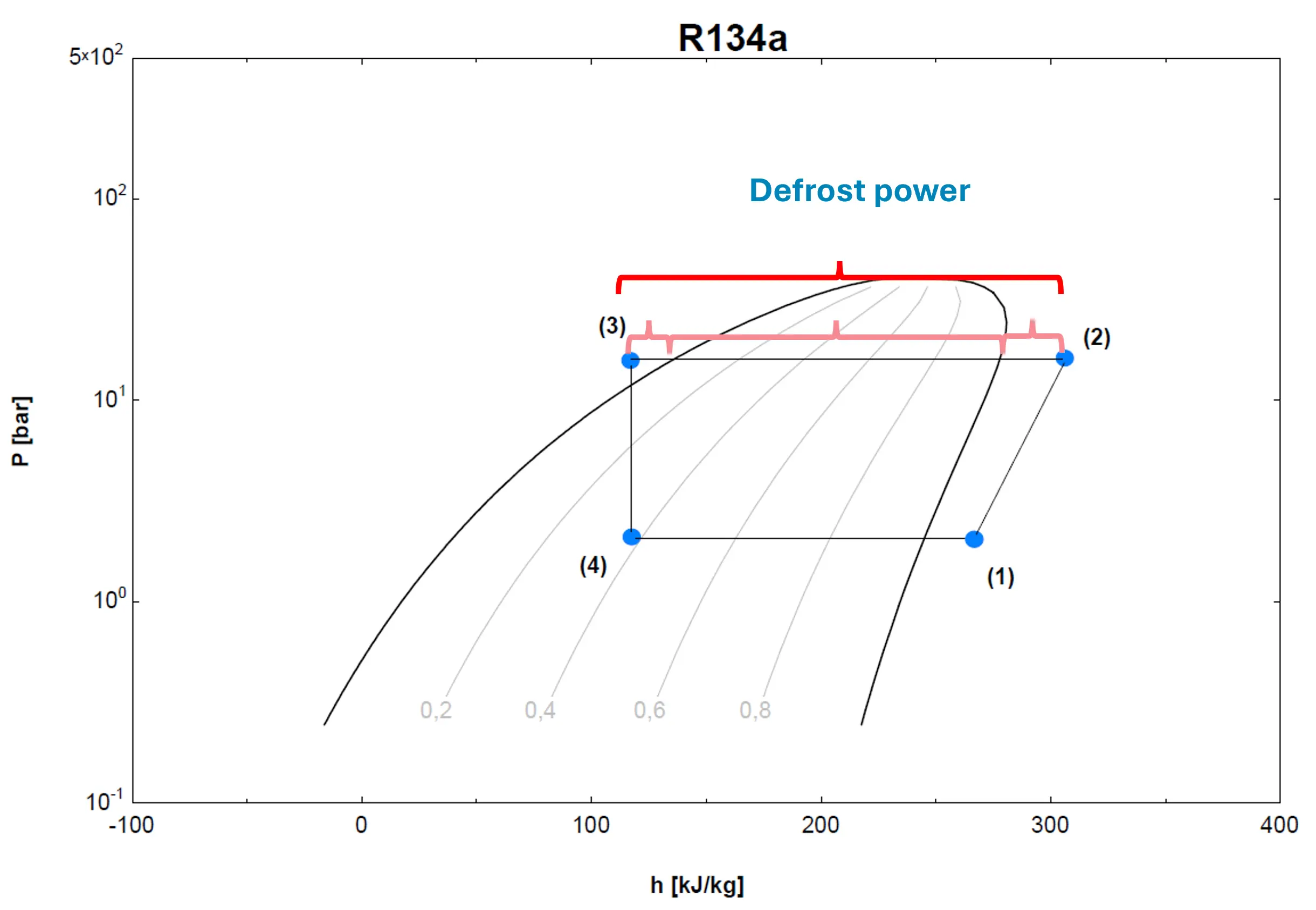

Hot gas defrost stands out as a highly effective method of removing frost from evaporators in refrigeration systems. This technique connects the compressor discharge directly to the evaporator, downstream of the expansion system, using the heat generated during refrigerant compression to melt the accumulated ice. This results in a defrost power equal to the power absorbed by the compressor as shown in the Mollier diagram below.

This method is particularly useful in refrigeration plants that require frequent and efficient defrosting, offering a simple but effective system where the heat generated and the cold are at the same point.

Measures and precautions for hot gas defrost

To ensure the safety, performance and efficiency of hot gas defrost, it is crucial to implement certain measures:

| Precautions | Installation safety measures |

| Preventing Liquid Backflows to the Compressor | Suction separator |

| Preventing Mixing of Hot Liquids or Gases with Cold Liquids | Pressure regulating valve |

| Avoiding pressure surges | Pressure relief valve |

| Preventing Liquid Expansion in the Suction Line |

Exploring variants of the method, the 3-pipe hot gas defrost offers a simplified alternative. It reduces the temperature of the hot gas by means of a pressure-static valve. This allows cooling of the gas and its entry into the evaporator at reduced pressure and temperature. This minimises thermal stress and maximises efficiency. Thus, the gas returns to the compressors without the risk of condensation.

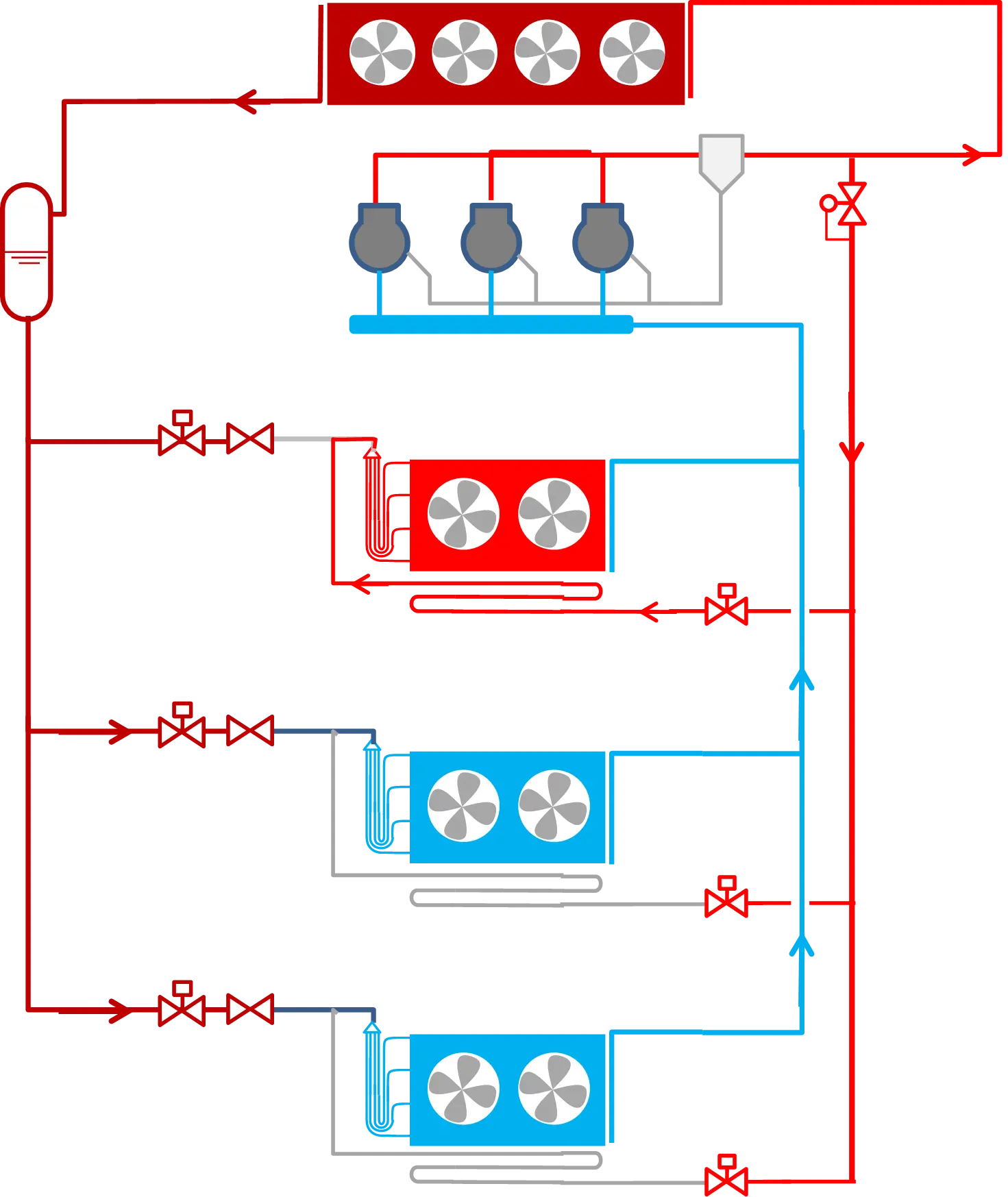

The 4-pipe system, on the other hand, uses cycle inversion in the evaporators. It allows using the condensing heat from the compressors to optimise frost removal. It involves more complex control of the hot gas flow to avoid overloads and ensure efficiency in the duty cycle.

These hot gas defrost methods are robust and effective solutions for refrigeration systems in INTARCON. They are suitable for medium and low temperature commercial and industrial applications, ensuring optimum performance and efficient cold cycle management.

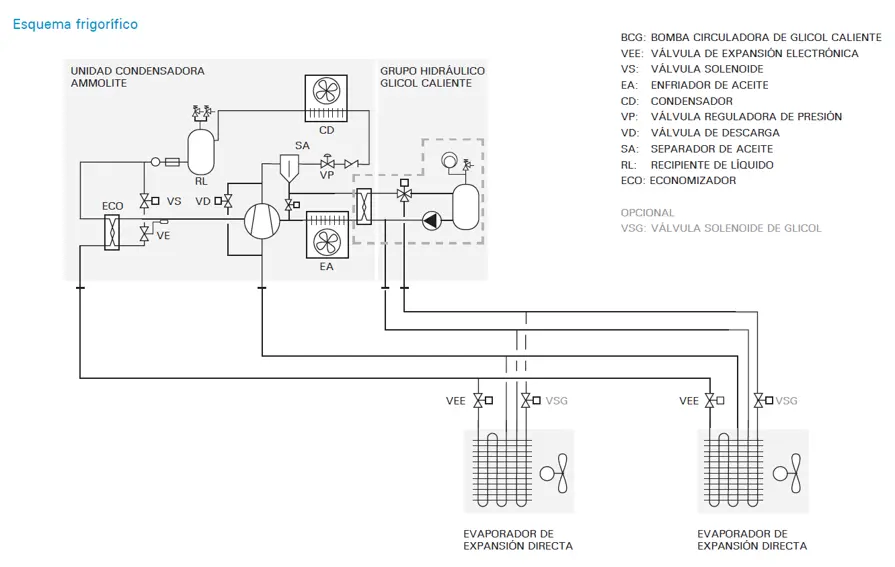

Hot glycol defrost

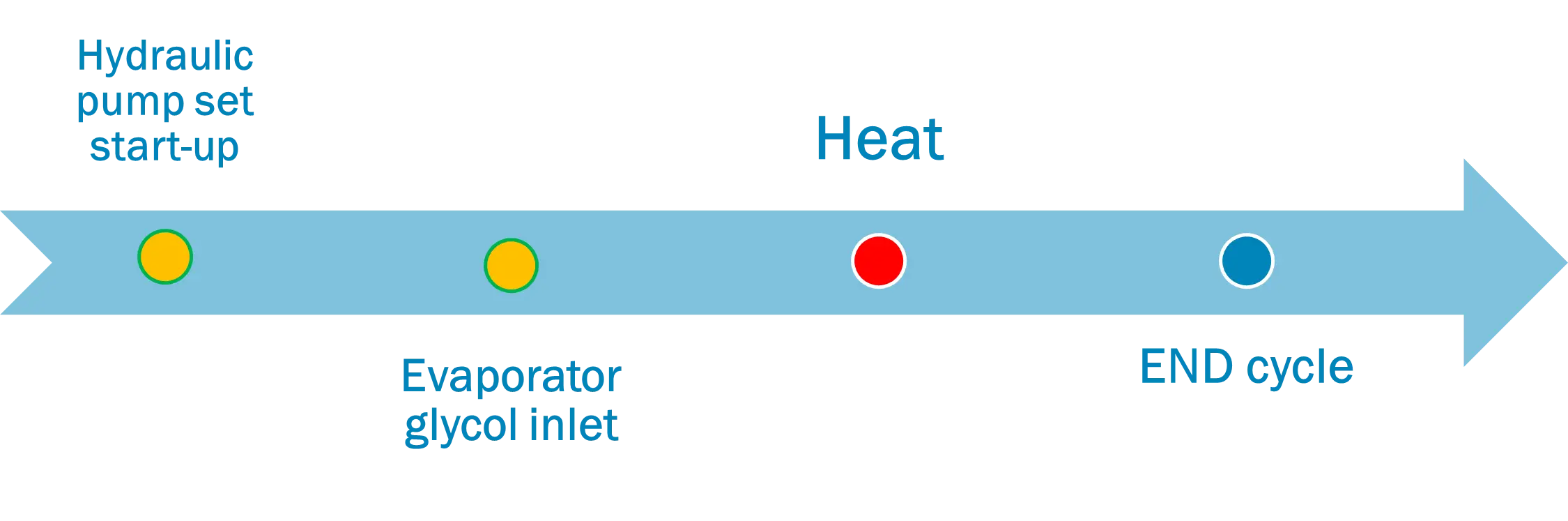

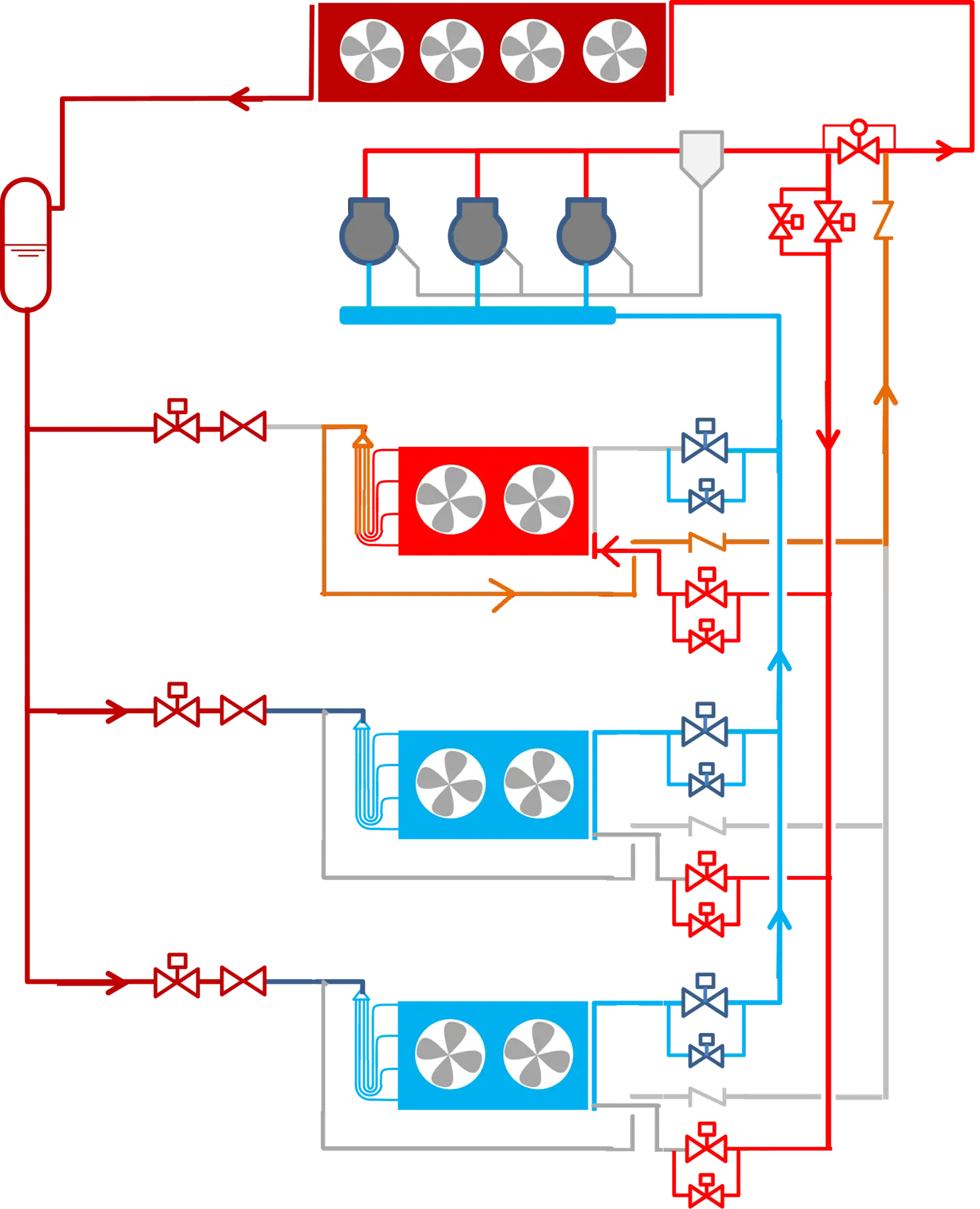

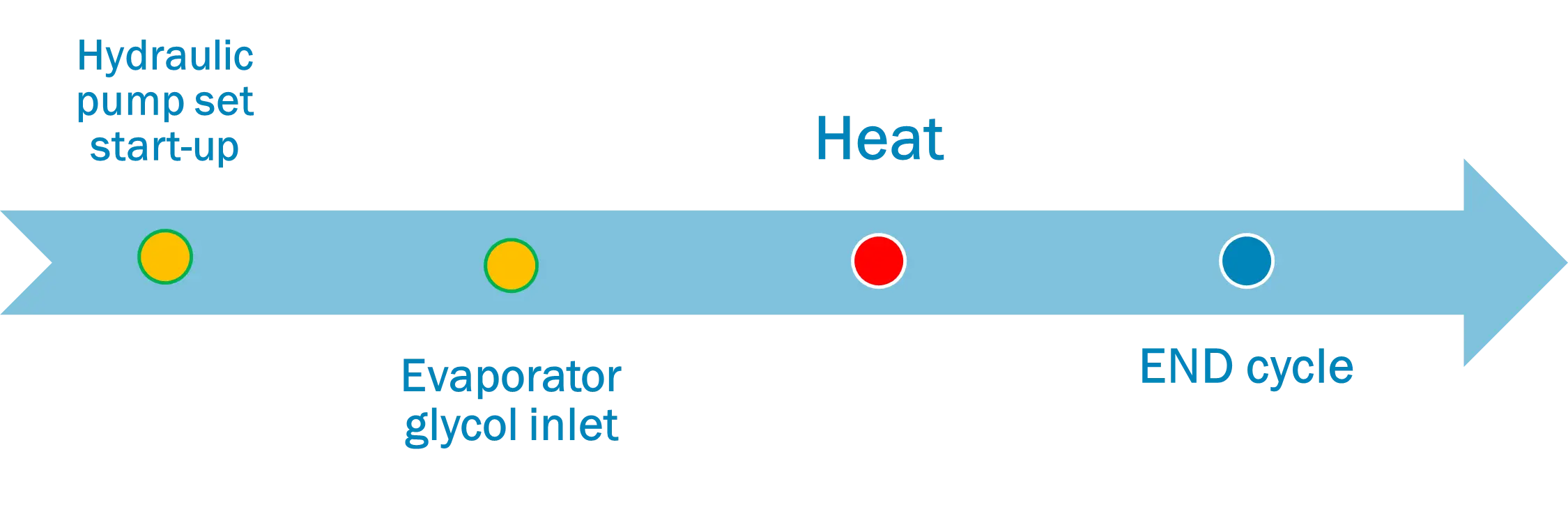

Hot glycol defrost is an efficient method that uses a heated glycol solution pumped through coils inside the evaporator to melt accumulated ice. This process begins with the opening of the glycol solenoid valve and activation of the hydraulic unit pump, allowing the hot glycol to flow directly into the evaporator.

During defrost, the hot glycol runs in a separate circuit in the evaporator, efficiently transferring its heat to the ice and facilitating its rapid and complete melting. This method is particularly valued for its ability to precisely control the defrost process without increasing the ambient humidity.

Once the target temperature is reached or the programmed time is reached, the defrost process is terminated. The glycol is collected and returned to the buffer tank for reuse. Installations must be prepared with suitable hydraulic connections for hot glycol.

Reverse cycle defrost

Reverse cycle defrost takes advantage of the reversibility of refrigeration systems. It converts the evaporator into the condenser and vice versa to melt the frost quickly. During this process, the chamber fan stops. The 4-way valve changes the direction of the refrigerant to the evaporator, which acts as a condenser. The refrigerant transfers heat to the accumulated ice and effectively melts it.

After defrost is completed, the cycle continues with the refrigerant in a liquid state. This passes through the filter and the thermostatic expansion valve to the condenser, which now functions as an evaporator. Thus, the cycle is completed. This method is notable for its speed and energy efficiency, ensuring effective defrost without compromising the performance of the refrigeration system.

In the Mollier diagram, it can be seen that the entire condensing power is used for defrost. It includes both sensible and latent heat of condensation. This demonstrates the efficiency and optimisation of this method for removing frost in evaporators.

Applications, advantages and disadvantages of each of the defrost types

| Defrost type | Application | Advantages | Disadvantages | |

| Air | Systems and cold rooms > 4ºC High humidity equipment Equipment for warehouses | Simple and cheap Low consumption Reduced maintenance Optimised drying | Prolonged time Temperature limits Damage to unpacked product

| |

| Electrical resistance | Warehouses, supermarkets Commercial Industrial systems

| Speed Simplicity Precise control | High energy consumption Risk of overheating Maintenance | |

| Hot gas | 3 tubes (3T) | Supermarkets, coldrooms | Simplicity Lower initial cost Regulation and control Reduced mechanical and thermal stress | No heat recovery Limited COP System performance |

| 4 tubes (4T) | Industrial refrigeration systems | Higher energy efficiency Lower chamber temperature impact Heat recovery COP higher than 3 | Complexity High initial cost Penalty for compressor consumption Differential pressure management Caution desynchronisation Frequency of defrost limited 2 to 1 evaporators | |

| Cycle reversal | HVAC-R systems | High defrost performance Energy efficiency Localisation of heat source Fast execution | Complexity Risk of liquid hammer Operational wear | |

| Hot Glycol | Ammonia Turbofrezzer Industrial CO2 applications | Efficient, simple Avoids the risk of refrigerant water hammering Cycle uninterrupted Controlled area temperature | Needs pumping system Complexity Cost Control | |