Refrigeration in dryers

INTARCON2024-12-12T07:48:04+01:00The drying process currently plays a crucial role in the food industry by allowing the drying of certain products and increasing their shelf life, providing safety by allowing food safety to be maintained for a longer period of time. However, to ensure that products maintain their safety and organoleptic properties, it is essential to have adequate refrigeration systems in dryers that control temperature and humidity during storage.

What is a dryer?

A drying room is a space designed to develop the drying process in a natural or artificial way in certain products. Drying is an indispensable preservation method in the food industry, as it increases storage time and reduces the weight and volume of the treated product.

During the drying process, the free water in the food is evaporated, reducing the amount of water in the food, and thus the capacity to carry out biochemical reactions that would alter the product over time. This process can be carried out naturally, by exposing it to the sun or wind, or artificially, through the use of industrial dryers.

Industrial dryers use hot air to evaporate water from feed. Hot air can be generated by a variety of sources, such as gas burners, heat pumps, electric heaters or steam boilers. Such air can cause excessive heating of the food, altering the quality and properties of the food.

By implementing effective cooling systems, the temperature and humidity in the dryer can be controlled, which helps to maintain the quality, taste and texture of the products.

Refrigeration can also help to reduce the loss of nutrients during drying. These nutrients are heat sensitive (thermolabile), such as vitamins C or B and proteins, and can be degraded when the food is exposed to high temperatures. Refrigeration helps to protect these nutrients by keeping the air temperature at a safe level, thus preventing their denaturation or destruction.

In the case of tobacco drying, for example, refrigeration is especially important to prevent the leaves from burning. Tobacco leaves are very sensitive to heat, and can easily burn if exposed to high temperatures. Refrigeration helps to keep the leaves at a safe temperature, preventing them from burning.

Types of drying

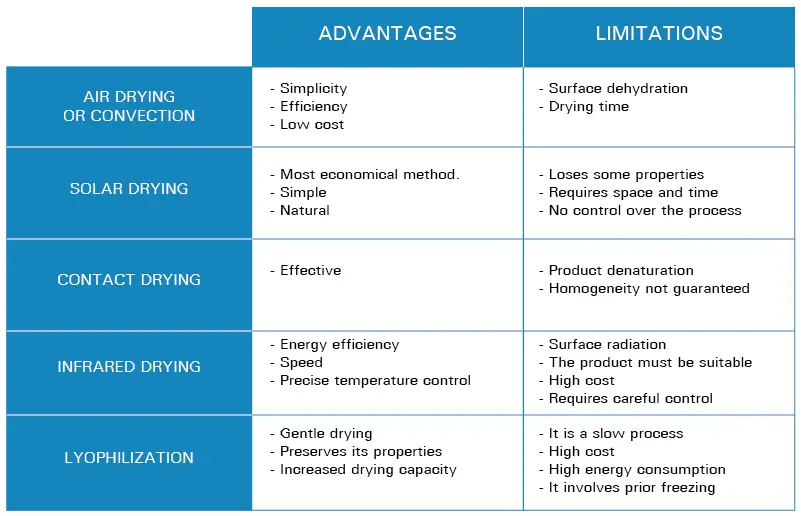

There are several methods for cooling air in dryers, the main types being:

Air or convection drying.

It is the most common process because it is an economical, efficient and simple solution for heavy-duty industrial and food products. Refrigeration comes into play in this type of drying.

Advantages of air or convection drying.

- Simplicity: It is a relatively simple process to implement and maintain.

- Efficiency: It can reach high temperatures, which allows products to be dried quickly.

- Cost: It is a relatively inexpensive method.

Limitations of air or convection drying.

- Surface dehydration: Hot air can completely dehydrate the surface of the product, causing cracks or a heterogeneous result.

- Drying time: This can be a slow process, depending on the product and the allowed drying temperature.

Solar drying

As the name suggests, this is the exposure of the product to the sun.

Advantages of solar drying

- More economical method.

Limitations of hot air drying

- The product loses some of its properties such as vitamins, for example.

- This method requires a lot of space and time.

- There is not much control over this process.

Contact drying

This method involves the transfer of heat through a wall or surface to dry the product.

Advantages of contact drying

- It is very effective in drying processes in heavy industry.

Limitations of contact drying

- Direct contact of the product may cause denaturation of the product.

- The homogeneity of the process is not guaranteed.

Infrared drying

Infrared drying is a dehydration method that uses infrared radiation to remove moisture from products. This technology takes advantage of the ability of infrared waves to penetrate the material and directly heat the moisture present inside. In addition, it can be combined with hot air drying and is used in those products where the main purpose is to give a toasted effect to the surface.

Advantages of infrared drying:

- Energy efficient, as it heats the water directly inside the product, minimising heat loss.

- Fast, Infrared radiation can heat products quickly and evenly.

- They allow precise temperature control, which helps to avoid overheating and degradation of certain heat-sensitive products.

Disadvantages of Infrared Drying:

- Infrared radiation only penetrates the surface of the products.

- Products must be suitable for infrared drying.

- These systems are costly.

- It requires precise monitoring and control in order not to damage the products.

Lyophilisation

Lyophilisation is based on freezing the product at very low temperatures and then subjecting it to pressures close to vacuum, causing the water contained in the product to sublimate when it is below the triple point in the phase diagram. This process makes it possible to dry products with thermolabile compounds and maintain their shape and organoleptic characteristics.

Advantages of lyophilisation

- Gentle drying

- It retains most of its organoleptic properties.

- Process with higher drying capacity (99% of water content)

Limitations of lyophilisation

- It is a slow process

- Its costs are high

- High energy consumption

- Involves prior freezing

In addition, there are other methods such as fluidised bed drying, which is often used to dry seeds or grains. And dielectric drying based on homogeneous and gentle drying by microwave and radiofrequency.

How to optimise cooling in dryers?

To ensure effective cooling in dryers, it is important to follow some key guidelines:

- Proper system design: Make sure that the refrigeration system is efficiently designed and correctly sized for the needs of your dryer.

- Temperature and humidity control: Use advanced control systems to keep temperature and humidity at optimal levels for your products.

- Regular maintenance: Perform regular maintenance of your refrigeration equipment to ensure that it is working optimally.

- Constant monitoring: Implement monitoring systems that allow you to closely supervise conditions inside the dryer and take corrective action if necessary.

- Energy efficiency: Consider energy efficiency when choosing your cooling systems to reduce operating costs.

Refrigeration equipment for dryers

Depending on the size of the project INTARCON offers a range of cooling solutions for dryers to control the temperature of any product. In addition, we offer a wide range of alternatives with different gases and a specially developed product range in our product portfolio.

Our experience in the industry supports us and with the development of our range of high humidity equipment mainly for commercial applications. These are semi-compact humidity-controlled refrigeration units consisting of a silent condensing unit or centrifugal unit and an evaporator unit, designed for applications with high relative humidity.

These units stand out for their controlled relative humidity conservation, which in certain products such as fruit, vegetables, flowers, etc., requires the control of the relative humidity in the chamber within a certain range. In addition, the evaporators have a double air impulsion through oversized coils in order to obtain a high level of relative humidity inside the chamber of around 95%, thus avoiding the loss of humidity and weight of the product.

In addition, these units also incorporate advanced electronic regulation for temperature and humidity control inside the chamber.

- Multifunctional digital remote control with temperature and relative humidity display.

- Relative humidity control in the regulation range from 60% to 95%.

- Optionally, active humidification kits with steam lances and dehumidification and humidification kits can be integrated.

Humidity control in the chamber is passive, acting on the evaporator’s ventilation flow rate, without the addition of water vapour. The actual range of humidity control depends largely on the chamber conditions, absolute humidity outside and the type of product.

And, on the other hand, the development of specific solutions with natural refrigerants for larger installations of an industrial nature. This industrial equipment includes the option of heat recovery to support the hot water loop in the drying process, making it possible to reduce the carbon footprint generated by typical combustion systems. Such is the case of chiller plants or chillers mainly developed with NH3 (ammonia), CO2 (carbon dioxide) and R290 (propane).

In addition to the quality and easy installation of the equipment, INTARCON stands out for its capacity for advice and design of refrigeration projects adapted to the needs of each client.

We have a large commercial and prescription team with extensive experience and training for the execution of projects aimed at this sector, whose objective is to offer the best solution, analysing all the alternatives and proposing the most efficient, reliable and sustainable solution to the client.