The best cold rooms for fruits and vegetables

INTARCON2022-12-20T18:45:25+01:00Why are cold rooms for fruits and vegetables important? The World Health Organisation (WHO) recommends daily consumption of fruit and vegetables, with a consumption per person per day of at least 400 grams. These products are perishable, so it is essential that food safety is guaranteed for as long as possible, avoiding spoilage and thus preventing health problems for people.

The importance of good refrigeration for fruits and vegetables

The safety of fruit and vegetables is guaranteed if they are kept at optimum temperature conditions for each type of fruit and vegetable, as well as a controlled humidity percentage.

This temperature and humidity control is responsible for reducing the reproduction speed of many microorganisms that can cause product decomposition, favouring the loss of product quality and avoiding possible illnesses in consumers.

Important factors of cold rooms for fruits and vegetables

The cold rooms of fruit and vegetables has three important factors: temperature control, humidity control and ventilation. There are other factors that may influence the good preservation of these products.

Temperature control

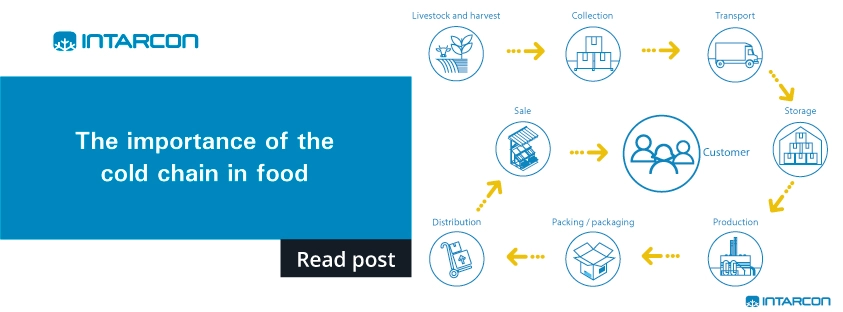

Fruit and vegetables are very vulnerable to breakage in the cold supply chain, which can seriously affect food quality. Products with poor temperature maintenance will arrive at the sales counter with a worse appearance and odour, and can even lead to bacterial contamination.

There are tools to control the temperature in the cold rooms of products, such as the kiconex monitoring and control system.

Kiconex is a system for equipment and installations that collects data in real time. This system makes it possible to analyse the operation of equipment and installations, controlling chamber temperatures and anticipating possible problems thanks to alarm management.

Humidity control

As well as the temperature, the correct percentage of humidity in the fruit and vegetable chamber allows the best and longest conservation of these products.

Humidity control is important. Because, during the ripening process, products transpire and lose water naturally. In order to avoid the loss of hydration and the acceleration of the putrefaction of the product, the cold rooms for fruits and vegetables must have equipment that provides a relative humidity between 85 and 90%. The adequate relative humidity for each product will depend on the surface/volume ratio. Excessive humidity may cause mould growth on the fruit and, therefore, a loss of value.

Ventilation

For the proper preservation of fruit and vegetables, it is essential that they are refrigerated in a controlled environment. Fruits and vegetables are mainly very delicate products with very demanding refrigeration conditions, so much so that even in a poorly ventilated environment, the products would not ripen, although they would deteriorate.

The ripening of fruits and vegetables takes place with the process known as fruit respiration, in which the product acquires oxygen and converts it into carbon dioxide. This process is responsible for the ripening of the fruit and for altering some main attributes of the fruit, such as colour, flavour, texture, and overall quality of the fruit for optimal consumption.

This is why good ventilation is so important, because at low oxygen levels, the fruit will not ripen. However, this would lead to fermentation processes that would also deteriorate the quality of the fruit for optimal consumption.

It is recommended that there should be a ventilation flow of approximately 10-15 min for every 8 hours of storage in the refrigeration chamber. In addition, it is important that the minimum oxygen levels are always maintained above 2% at a controlled temperature, pressure and humidity.

Finally, it should be noted that it is important for proper ventilation and thus cooling that the ventilation flow does not impinge directly or at high speed on any fruit or vegetables, as it could deteriorate them at higher speeds. In addition, it could alter the climatic conditions of the refrigeration and preservation process of fruit and vegetables more quickly.

Other factors in fruit and vegetable cooling

Storage material.The Food and Agriculture Organisation of the United Nations recommends storing fruit and vegetables in plastic boxes (as far as possible), with ventilation. In case of packing the boxes, they should be packed on pallets, preferably in plastic. Plastic reduces the risk of spoiling the produce by bugs or wood splinters.

Specialised transport. Refrigerated transport is not necessary for short distances, but it is necessary for long distances. Refrigerated transport, when the outside temperature can reach 40 ºC, is recommended for medium and long distances. Imagine a truck loaded with pears from Almeria (Spain) that is sent to the United Kingdom, it can take up to 3 days to arrive in normal conditions. If the outside temperature is 40ºC with a tarpaulin roof on the lorry, the fruit may not arrive in good condition. However, with refrigerated transport, the temperature inside slows down the ageing of the product.

Methods of refrigeration of fruit and vegetables

There are three methods of refrigeration of fruit and vegetables: preservation, freezing or deep-freezing.

- Preservation or refrigeration: is the method by which fruit and vegetables are kept between 0 and 10 degrees Celsius in order to slow down the growth of microbes in the product. Read more.

- Freezing: with this method, fruit and vegetables are brought below freezing point, between -18 and -25 degrees. Read more.

- Ultrafreezing: in this method, fruit and vegetables are subjected to temperatures below -40 °C for short periods of time, usually less than 120 minutes.

The best cold rooms for fruits and vegetables

The best cold rooms for fruits and vegetables are those with a cold room motor adapted to the needs of these products.

INTARCON has a wide range of solutions for small and medium-sized cold rooms, as well as for large cold rooms.

For smaller cold rooms, we can select INTARCON’s high humidity units consisting of a silent or centrifugal condensing unit, and a double airflow evaporator unit, this type of evaporator allows the air not to reach the product directly.

These units have advanced electronic temperature and humidity control inside the chamber, allowing passive relative humidity control in the regulation range of 60 to 95%.

For larger cold stores or fruit and vegetable refrigeration installations, it is common to have refrigeration equipment based on indirect systems for several reasons:

- It limits the risks associated with refrigerant leakage to the whole installation.

- It reduces the gas load.

- It opens up the possibility of using natural gases such as R717, R290 or R744.

Also, in this type of installation, it is common to find, in addition to the cold rooms for product storage, working or handling rooms for washing the product, putting it in trays or processing it for the third range.

In indirect systems, the refrigerant gas is confined in the part of the refrigeration equipment that is responsible for the generation of cold. There the cooling power is transferred to an intermediate fluid (glycol or water), by means of an exchanger. This intermediate fluid, driven by hydraulic pumps, transports it to the air coolers, exchangers, coils…

What is passive humidity regulation?

Humidity control in fruit and vegetable chambers is carried out passively, acting on the evaporator’s ventilation flow rate, without the addition of water vapour. The actual range of humidity regulation depends to a large extent on the conditions of the chamber, absolute humidity outside and type of product.