The preservation of dairy products

Jose Miguel Molina2022-09-06T09:59:12+02:00The daily consumption of certain products with a high vitamin content makes the correct preservation of dairy products essential for optimal processing and consumption.

Dairy product processing.

The processing of dairy products requires a high degree of processing regardless of the type of product. For example, milk and cheese are not processed in the same way, as cheese has a much more elaborate process. However, all dairy products must have safety in common in order to be consumed safely, as they are processes with a high proliferation of microorganisms during their elaboration.

Like the vast majority of products, dairy products also need to be refrigerated for proper processing and preservation due to being a perishable product.

Dairy product processing.

Refrigeration plays an important role in the production of dairy products, because without it, the production of dairy products would not be possible. For the production of dairy products, refrigeration is necessary in processes such as:

Descremation

This process is based on the separation of cream and whole milk, resulting in skimmed milk, which must be refrigerated at around 4ºC in order to be able to continue with the dairy product production process without the raw materials suffering any loss of properties or being unable to guarantee their safety.

Pasteurisation

This process is based on ensuring the safety of dairy products so that they can be consumed safely and under optimal conditions. However, it could also be used to alter certain product properties, for example, the texture and viscosity of yoghurt.

Pasteurisation involves exposing a product to a sudden change in temperature. First, the product is exposed to a high heat treatment in order to eliminate pathogenic bacteria and reduce its microbial activity. This product is then subjected to a thermal shock in which refrigeration comes into play, responsible for preserving a product in a controlled environment in which, depending on the type of product, it will have specific needs, although its main objective is to maintain the reduced microbial activity, thus extending its shelf life.

Both processes are irreplaceable in the production process of any dairy product, as they are essential to guarantee the safety of the food and its subsequent preservation in optimum conditions.

Refrigeration and maturation in the preservation of dairy products.

As mentioned above, the demanding preservation needs of dairy products due to their high microbial activity make refrigeration or ripening two key products.

In the preservation of dairy products, refrigeration is responsible for maintaining optimal conditions in a climatic environment of around 4ºC so that after processing the product, microbial activity does not recover quickly, which could damage the product’s properties or even endanger the consumer’s health.

But what is ripening of dairy products?

Maturation is the process of food transformation that occurs in some foods, in which their properties are altered, in this case their texture, flavour and hardness, for example. This process mainly takes place in the production of cheeses, which are stored in rooms specifically conditioned to the temperature and humidity required for each type of cheese. This helps to obtain certain properties depending on the type of cheese to be produced. The average temperature for a ripening process is between 9 and 11º with a relative humidity of 85-95%, although these conditions vary. We can distinguish between:

- Tender: they are matured for less than 30 days.

- Semi-cured: they are matured for 1 to 3 months.

- Cured: they are matured for 3 to 6 months.

- Old: they are matured for 6 to 9 months.

- Aged: they are matured for more than 9 months.

After finishing this process, the cheeses must also be refrigerated at around 4º C in order to extend their optimal conditions for consumption and, consequently, slowing down the ripening process.

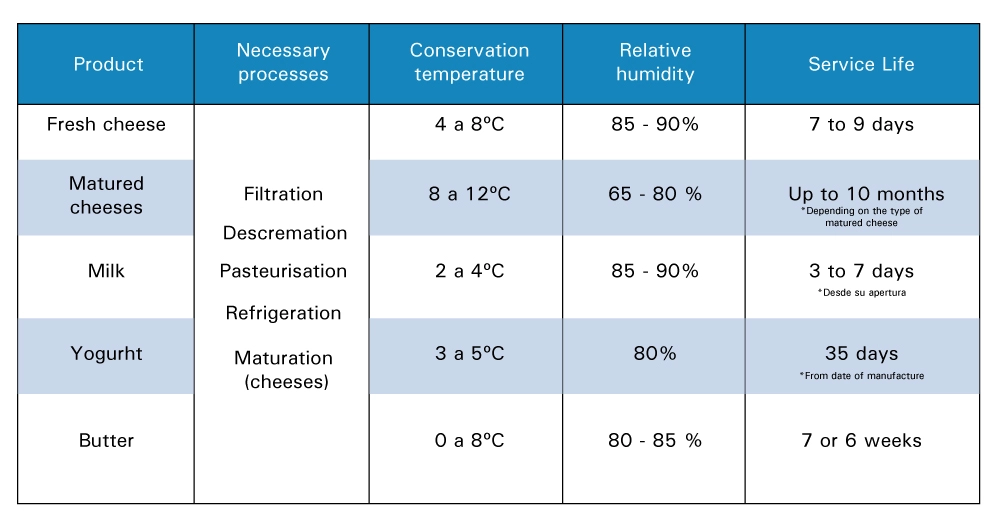

Properties of dairy products

For a correct production process and preservation of products, it is important to know what their refrigeration needs are. In this way, we will ensure that during the useful life of the product, its conditions and properties in terms of nutritional value, flavour, texture, etc. are preserved.

Recommended equipment for preserving dairy products

At INTARCON we have certain equipment that adapts to the necessary conditions both for dairy production processes and for subsequent preservation. For a correct selection we have our online Calcooling equipment selection software, this tool allows us to know which equipment is best suited to the needs of our product depending on the size of the space to be refrigerated, the ambient temperature, the number of openings in the refrigerated space, the humidity, the properties of the product, the product load inside the space, etc.

However, within this selection we can highlight the equipment with special conditions for refrigeration, such as: