Refrigeration systems

INTARCON2022-11-04T11:09:20+01:00What is a refrigeration system?

A refrigeration system is a mechanical process or arrangement that is responsible for lowering the temperature between two points. For this process to take place, the thermodynamic properties of matter are involved, which are responsible for transferring thermal energy or heat between two points.

The main difference between a system and a refrigeration circuit is the complexity of the circuit, as systems are only a simple arrangement of the circuit, in which other variables such as mass balance, energy, heat transfer, etc. become more important.

There are two basic configurations of a refrigeration system depending on the method of refrigerant injection or its construction.

Compression refrigeration

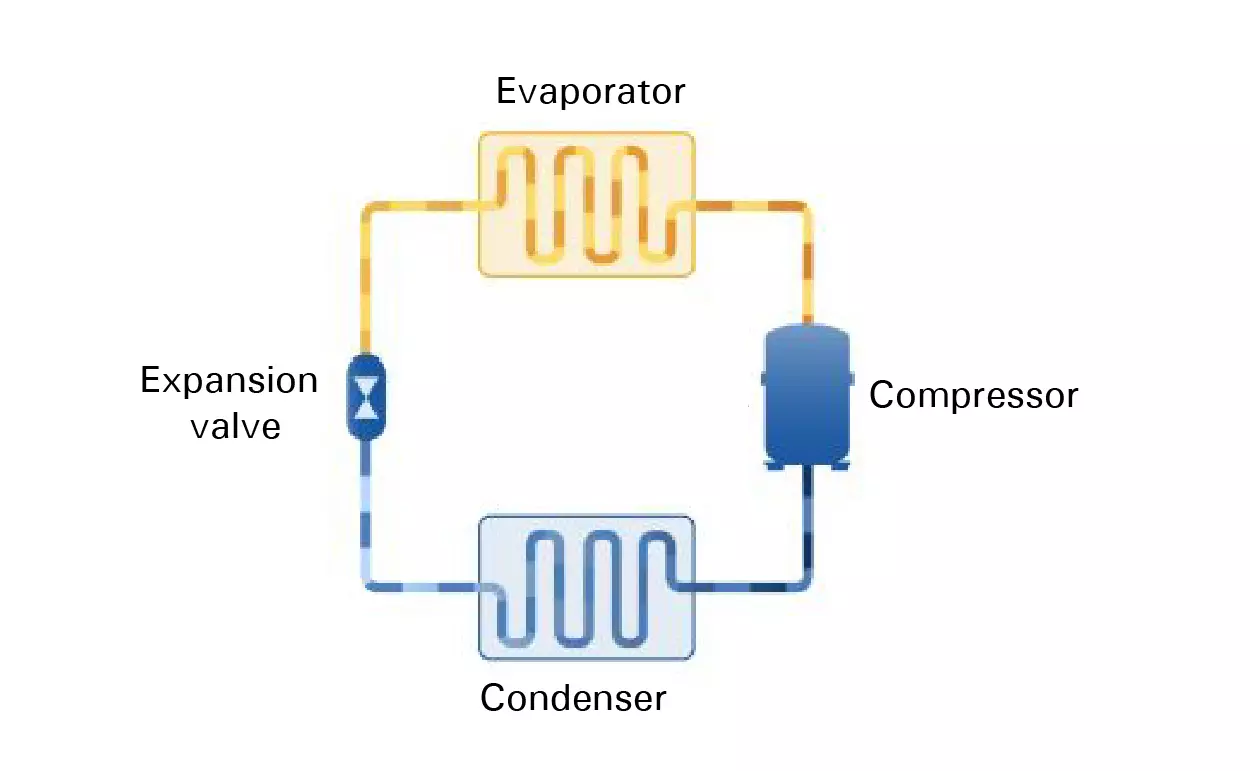

It is based on the operation of the mechanical energy of the circuit through the compression of a refrigerant fluid. When it condenses, this fluid gives off latent heat at a lower temperature than that which was absorbed when the refrigerant itself evaporated. The compression of the refrigerant fluid in the compressor is responsible for maintaining the cycle which, after passing through the evaporator, the expansion valve and the condenser, is subsequently repeated, passing through different pressures and therefore different temperature conditions.

Absorption refrigeration

Its operation is the same as in compression refrigeration, since it involves producing cold through the transfer of heat by means of changes in the state of certain refrigerant fluids. In this case, it is not the compressor that is the key aspect but the properties of the refrigerant fluid, which is able to absorb the properties of another substance in the vapour phase…

Examples of such substances are lithium bromide, ammonia or water in vapour phase, although this method is usually only used when there is a cheap or waste heat source, because it is an economical method, but not very efficient, since, depending on the fluid used, it cannot cool to temperatures below the freezing point of water, for example.

Types of refrigeration systems

As mentioned above, refrigeration systems can be classified according to the method of refrigerant injection or construction.

Refrigeration system for cold rooms

Different types of refrigeration systems can be used in cold rooms due to the many factors that directly affect the refrigeration needs for the preservation and maintenance of the stored product. For example, the dimensions of the cold room, the number of door openings, the load of the cold room, the requirements of the stored product, the type of construction material of the cold room itself…

The main cooling systems are:

- Direct refrigeration systems: compressed and condensed refrigerant gas leaves the equipment and is distributed to the remote units (evaporators). This type of system is mainly used in smaller, commercial applications due to refrigerant charge limitations in the industry.

- Indirect refrigeration systems: the refrigerant gas is confined in the cooling generation zone, where the cooling power is transferred to a secondary fluid by means of an exchanger. The fluid (water, glycol or brine), driven by a pumping system, conveys it to the final elements such as air coolers, exchangers, tank coils, etc. This type of system is mainly used in large and industrial applications because the use of a secondary fluid such as glycol, brine or water lowers the cost of the refrigerant charge in this case, showing a high performance.

Basic refrigeration system

It is made up of:

- Compressor: responsible for compressing the refrigerant fluid and increasing its pressure in order to transport heat throughout the circuit.

- Evaporator: this is responsible for reducing the pressure and temperature of the refrigerant fluid after leaving the compressor until it becomes a liquid at a lower temperature and pressure, transferring the heat to the outside.

- Expansion valve: responsible for increasing the pressure of the refrigerant until it becomes a liquid after passing through the condenser.

- Condenser: this is responsible for sending the thermal energy of the refrigerant liquid to the outside which, until it reaches the compressor again, will be converted back into gas due to the increase in pressure caused by the change in temperature of the refrigerant exchange.

Vapour compression refrigeration system

This is a compression system in which compressors are responsible for activating the refrigerant by compressing it to a high pressure and temperature after having produced the refrigerant effect. In this way, the compressed refrigerant transfers its heat to the outside and is condensed, returning to its liquid form, thus achieving the refrigerant effect during evaporation, which is the most common and basic process in refrigeration.

Ammonia refrigeration system

It should be noted that ammonia or NH3 refrigeration is currently an economical alternative and is more efficient. Its thermodynamic properties make it highly efficient, and it reaches temperatures down to -70ºC in direct expansion systems.

Ammonia refrigeration has certain advantages for its use:

- Superior thermodynamic performance compared to other refrigerants.

- It is an environmentally safe refrigerant with zero GWP.

- It has a low cost, and a smaller quantity is required for the same application than other refrigerants.

- Its strong smell can be a sign of quick identification in case of leakage.

- Ammonia refrigeration equipment is safer for preventive purposes.

Disadvantages include:

- Ammonia is not compatible with copper, so we cannot use it for its construction.

- Although a safe refrigerant, ammonia is a toxic refrigerant.

CO2 refrigeration system.

The main difference between CO2 and other refrigerants is the operating pressure at which it works. However, this makes it a high-density gas, achieving a higher cooling effect with a low circulating mass. Advantages of using CO2 as a refrigerant:

- GWP = 1.

- It is not flammable.

- Low toxicity (only dangerous in high concentrations).

- Contains a high heat transfer coefficient.

- High efficiency, low energy consumption.

- It has no long-term side effects.

- It is cost-effective and has no risk of obsolescence.

- High availability, as it is obtained as a by-product of different processes.

- Can be blended with POE, PGA and PVE lubricants.

CO2 also has a number of drawbacks and restrictions for its use in refrigeration:

- It works at higher temperatures and pressures than HFCs and other refrigerants.

- In case of leakage, CO2 accumulates on the ground, displacing the air; and being odourless, it cannot be detected olfactorily.

- CO2 is only suitable for new systems. As a high pressure, low critical temperature refrigerant, it is not suitable for conversion of systems with existing fluorinated refrigerants.

- The price of the system is high.

- It is governed by the Regulation F-GAS.