7 Keys to improving energy efficiency in cold rooms

INTARCON2025-08-11T14:43:37+02:00Achieving good energy efficiency in cold rooms leads to energy savings in the installation. Below we are going to analyse 7 keys to improve energy efficiency, and thus save on your electricity bill.

Avoid unnecessary door openings

Each opening of the cold room door leads to a temperature drop. In general, the room where the cold room is located will be at a higher temperature than the temperature inside the cold room.

There are chambers that, due to their location (type of establishment) or type of product stored, have more openings throughout the day than usual. For this reason, rapid opening and closing systems can be installed to mitigate the loss of cold in the cold room.

Maintenance and cleaning of the condenser coil

Maintenance of the condenser coil is key to ensuring energy efficiency in cold rooms. For this reason, a correct cleaning of the condenser coil is done in the following way:

- Check the condition of the outer casing of the equipment to ensure that it is not damaged by rust or other substances.

- Clean any dust and dirt that may be on the condenser coil.

- Check that there is nothing to prevent the correct evacuation of heat.

- Check and remove obstructions from the ventilation grilles and on the fan.

- Check that the maintenance registers of the equipment are properly closed to prevent unauthorised personnel from tampering with the equipment.

Maintain a reasonably low outside temperature to improve energy efficiency in cold rooms

The ideal way to avoid a large temperature difference between the cold room and the outside is to provide the installation with an area called an pre cold room. The antechambers are another key factor in energy saving, as the opening and closing of refrigeration doors is unavoidable. In many cases the doors remain open with the consequent thermal loss, which generates a considerable energy cost.

In fact, when we open the door of a cold room, there is a renewal of air, the magnitude of which depends on the size of the cold room doors and the indoor/outdoor temperature and humidity. This implies that the smaller the size of the cold room, the greater the air renewal, and of course the higher the electricity consumption.

Incorporate strip curtain in the door or equipment with air curtain

Unwanted air infiltration into the cold store can lead to a reduction in the temperature of the cold store and therefore to a loss of efficiency. For this reason, an option in cold rooms with a considerable number of openings per day, or with a prolonged opening due to loading and unloading of goods, it is recommended to install a strip curtain in the door.

Strip curtains or PVC hinged doors are an economical solution, which in turn is highly effective in preventing air infiltration into the chamber. These slat curtains have a negative point, which is that as they are a physical barrier, they reduce the visibility of the interior/exterior of the chamber and can increase the risk of accidents.

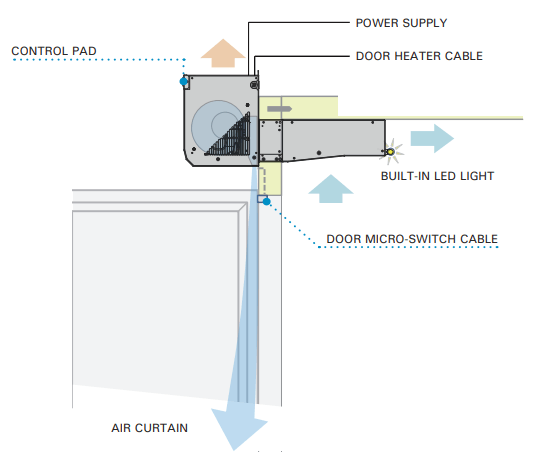

Another option to mitigate cold losses in small cold rooms is the installation of door units with an integrated air curtain. The air curtain creates an invisible barrier to prevent cold losses from the interior of the cold room, which is activated when the door is opened, and prevents the entry of warm air and the loss of cold air, with an efficiency of more than 50 %.

Location of evaporators in cold storage rooms

The wrong location of the evaporator unit can reduce energy efficiency in cold rooms, even leading to poor product preservation. Therefore, the evaporator unit should be installed at one end of the cold room, avoiding placing it above the door of the cold room and preferably driving it longitudinally in the cold room and transversally to the entrance door.

LED luminaires and lighting automation to improve energy efficiency in cold rooms

Lighting consumption in a cold room can be minimal, we recommend the installation of LED lights and an automatic lighting system, with a presence sensor and timers for switching off.

With these changes we achieve more efficient lighting, the reduction of heat emitted by the light is better with LED technology, and we avoid light consumption when there are no people in the cold room.

Installation of humidity and temperature sensors

Humidity and temperature are two fundamental parameters for the optimum operation of a cold room and for its energy efficiency, especially when the product is delicate, and a large part of its correct preservation depends on these parameters. Therefore, the installation of humidity and temperature sensors in a cold room and the good measurement of these can optimise and increase the performance of the cold room.

- Conservation at controlled relative humidity: The conservation of certain products, such as fruit, vegetables or cut flowers, requires the control of the relative humidity in the chamber within a certain range. These high relative humidity units are particularly suitable for storage rooms for fruit and vegetable products. The evaporators have a double air impulsion through oversized coils in order to obtain a high level of relative humidity inside the chamber of around 95 %, thus avoiding the loss of humidity and weight of the product.

- Temperature and humidity control: INTARCON equipment can incorporate advanced electronic regulation for temperature and humidity control inside the cold rooms.

With this in mind, and by doing so, we will be able to improve the energy efficiency of the cold rooms and the refrigeration installation.